Sheet metal parts are widely used in industries such as aviation, home appliances, electric power, fire protection and instrumentation. Bending is a kind of important sheet metal forming method, the bending process will directly affect the product forming quality and appearance.

At present, bending mainly adopts the method of manual assistance, which is labor-intensive and low in production efficiency. In order to reach the level of automation, informatization and intelligence, we need to improve the bending process urgently. The replacement of human labor by sheet metal bending robots has become the main development trend of the industry in the future.

In the process of bending thin sheet plate, we load and unload the sheet plates by manual method.

Sometimes we met problem, for example: the maximum thickness of the plate is 3mm, length and width of the plate size 1325mm×651mm, this plate weight is close to 27kg, the operator will be difficult to manually load and unload the plate, and it also has potential Safety hazard risk.

The robot bending unit processing process, the robot grabs material from the loading area, the robot cooperates with the press brake machine to bend sheets. After the bending is completed, the robot stacks the finished products in the unloading area.

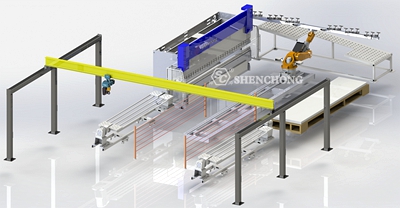

The purpose of the sheet metal bending robot unit: Robot automatic bending unit can improve the production automation and efficiency, reduce the use of labor. The production line includes loading and unloading system, and robot bending unit.

Case Review:

200KG ABB Robot Press Brake Automatic Bending Unit

Robotic Press Brake Case: ABB 500Kg Robot Bending Cell For Sheet Metal

Complete the layout of various functional areas for automated bending by combining the existing space around the CNC press brake machine.

It mainly consists of robots, end effectors (robot grippers), feeding devices, finished product stacking devices, bending machines (existing), flip frames, plate positioning andworkpiece centering platform (gravity centering tables), sheet turning frame, electronic control systems and safety and protection system.

First of all, we need to analyze the product. For example, for the product we mentioned above, the product maximum plate thickness is 3mm, the large size is 1325mm×651mm, and the product weight is close to 27 kg.

We comprehensively consider the factors of the robot: the robot arm motion range, the size of the working area, the self-weight of the gripper, the deviation of the center of gravity after grabbing the steel plate, and the attenuation of the effective load at the end of the robot, we can select robot with 6 axes, grabbing weight≥80 kg. Working Radius ≥ 2.5 m.

According to the workpiece size and process requirements (one-side bending, two-side bending or four-side bending), we make the design of the gripper, which total need 3 sets.

The gripper is mainly composed of a servo drive module, a cylinder, and a vacuum device. The suction cups are controlled in groups and equipped with a check valve, which can prevent the air leakage of a single suction cup from affecting the adsorption of other suction cups.

The loading device can realize the stack positioning. when the gripper grabs the material, it can effectively separate the upper and lower layer of the different specification material. And it can detect when the last sheet is left on the stack.

For this project, we adopt magnetic separator device, which can realize the easy separation of the upper material in the L-shaped direction.

The gravity centering platform includes a right-angled frame, a gravity slide and a positioning detection device.

When the material reaches the gravity centering mechanism, there is a short pause. The material slides down to the right-angled frame of the slide table by the weight of the workpiece on the gravity slide table.

And then the position of the sheet material is confirmed by the positioning detection sensor, so that the bending robot can accurately grab the material. At the same time, the ball structure is adopted to reduce the friction during the sliding process, so as to avoid scratches on the surface of the workpiece.

Because there are complex actions such as turning and following during the bending process, the material is often in a state of being vertical or above the suction cup.

When selecting suction cup, we need to consider lateral friction and material hardness, minimize the offset of the material relative to the suction cup and the suction cup deformation.

A closed area is formed by safety guardrails and related equipment within the working range of the sheet metal bending robot. It is also equipped with a three-color light prompt system as an auxiliary tool for the safety system.

The master control can stop in time when various abnormal conditions such as robot, bending machine start and stop, failure, refueling, loading and unloading, and safety alarms occur, and Alarm prompt.

Wuxi shenchong Robot automatic bending unit, combined with the application of modern vision technology, can ensure the precise positioning and bending angle, high-precision visual positioning correction, simplify the production process, reduce the cost and improve the product quality.