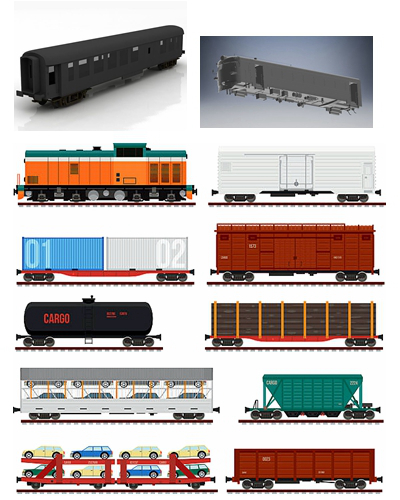

Train carriage is also called railway carriages, train cars, railroad cars. Train carriages are an essential component of railway transportation, and their production process involves multiple links and professional technology.

This article will provide you with a detailed introduction to the production process of train carriages. The production and manufacturing of railway carriages is usually a complex process that requires multiple stages and different professional skills.

The following is the general production process of railroad cars.

Design and planning are crucial steps in the production process of railway carriaes.

The designer develops a carriage design plan based on customer needs and railway company regulations, including the shape, size, materials, functions, etc. of the carriage. Designers need to consider factors such as the structural strength, stability, weight, and safety of the carriage.

1) Determine the type and specifications of the carriage, and determine the size parameters such as length, width, and height of the carriage as needed.

2) Design the structure and materials of the carriage, including the skeleton, body shell, doors, windows, and other parts.

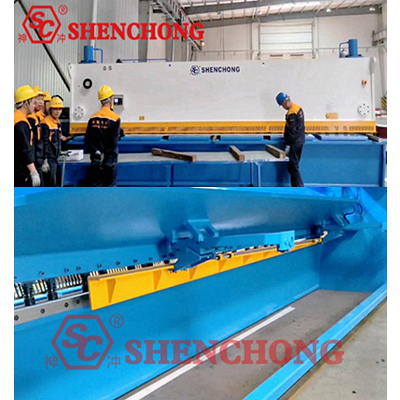

These structural components are generally made of metal sheets, and at this point, we need to use sheet metal processing equipment to process the confirmed raw materials. Different materials and structures require the selection of different equipment.

3) Design the internal layout and equipment of the carriage, including seats, restrooms, electrical equipment, and other parts.

After the design and planning are completed, raw material procurement is required. The main raw materials for the railway carriage include steel, aluminum alloy, glass, wood, etc. These raw materials require quality inspection and acceptance to ensure compliance with design requirements and standards.

Carriage body processing is one of the core links in carriage production. The frame is the skeleton of a carriage, usually made of steel material.

Firstly, it is necessary to carry out processing processes such as cutting, bending, welding, drilling, etc. of steel or aluminum alloy to ensure the strength and stability of the frame.

Choosing a high-precision CNC plate shearing machine can produce high-quality sheet metal parts, which is conducive to ensuring the quality of welding the frame plate in the later stage. Of course, the bending forming process is also an important step. Manufacturers can choose high-quality CNC hydraulic press brake machines to improve production efficiency.

After the processing of various accessories, the production and assembly of parts such as the body shell, doors, windows, etc. are carried out.

The floor and wall panels of the railroad car are usually composed of multiple layers of materials, such as steel plates, wooden boards, insulation materials, etc. These materials need to be cut and processed, and then installed on the frame.

The doors, windows, and skylights of the carriage are usually made of glass and metal. These components need to be cut and processed, and then installed on the railroad car.

Metal door frames and window frames are also processed using bending machines.

Stainless Steel Doors And Windows Manufacturing And Characteristics

Aluminum Alloy Doors and Windows Manufacturing And Bending Problems

The interior decoration of the train carriage includes seats, floors, walls, ceilings, toilets, and other parts. These parts require precise processing and assembly to ensure compliance with design requirements and standards.

The equipment installation of the train car includes electrical equipment, air conditioning equipment, ventilation equipment, and other parts. These devices need to be installed and debugged according to design requirements to ensure normal operation.

The production process of the railroad car requires multiple quality inspections, including raw material inspection, production process inspection, finished product inspection, etc. Only after passing strict quality inspection can they be sold and used before leaving the factory.

The above is a simple train carriage manufacturing and production process. The actual situation may vary depending on factors such as manufacturer and model.

The production process of train carriages is a complex project that requires the coordination of multiple professional technologies and links. Only through meticulous production processes and strict quality inspections can the safety, reliability and long-lasting use of the carriages be guaranteed.