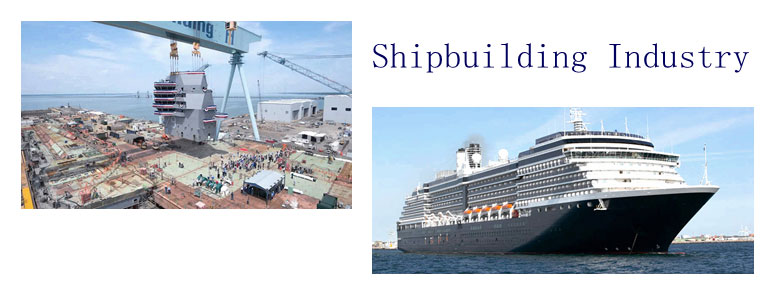

With the continuous development of the global economy, shipbuilding industry has gradually become an important industry to revitalize the equipment manufacturing industry in various countries. With the increasing demand of ship market at home and abroad, the demand of equipment for shipbuilding enterprises is also increasing.

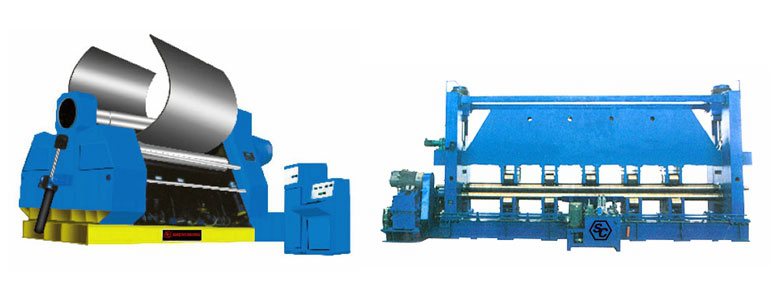

Among them, the super large CNC shipbuilding plate rolling machine is the necessary equipment for manufacturing large ships. This article will introduce you the marine plate bending roll machine to help you better choose and use.

Marine plate rolling machine is a kind of bending rolls, suitable for rolling ultra-wide arc-shaped parts. It belongs to heavy duty equipment and is a large-scale rolling machine.

Generally, according to the requirements of customers, the manufacturer can design symmetrical and asymmetric three roll types.

Machine structure and working principle:

– The upper roller moves between the two lower rollers. The upper roller obtains hydraulic transmission through the hydraulic oil in the hydraulic cylinder acting on the piston rod.

– The two lower rollers rotate. They are meshed with the lower roller gear through the output gear of the reducer to provide torque for the rolling plate.

– There are multiple groups of supporting rollers under the working rollers to improve the rigidity.

– Rigid beam also provided on the rollers to improve the rigidity.

Super large marine plate bending machine for sale is the necessary equipment for manufacturing large ships. And it is the largest numerical control marine plate bending machine in the world at present.

The special rolling machine for ships is mainly used for rolling the arc plate of ship shell and press bending the groove bulkhead.

– Working rolls are 42CrMo, forged and tempered, HB220-260.

– The comprehensive mechanical properties are good, high strength and strong wear resistance.

– The hydraulic station of the plate rolling machine is integrated with the main machine, which is convenient for installation, transportation and use.

– Rolling arc or conical work pieces with a central angle of less than 180 degrees.

– The length of the work piece between 8 meters and 21 meters.

– The remaining straight sides are small.

– It is suitable for high load work and long service life.

The early developed shipbuilding rolling machine is a symmetrical plate bending machine.

The three work rolls are symmetrically distributed. The upper roll and the lower roll are equipped with beam and support roll. Generally, two lower rollers are equipped with an independent driving device.

Symmetrical marine plate bending machine can roll conical or arc-shaped work pieces within 180°center angle of the circle. The length of the work piece to be processed must be controlled between 8 m and 21 m. And it cannot roll the whole circle.

The disadvantage of this machine is that it has no pre bending function and large residual straight edge.

With the continuous development of shipbuilding industry, asymmetric rolling machine for ships came into being.

The asymmetrical marine plate bending machine is usually level-down adjustment type. It makes up for the shortcomings of the previous generation of symmetrical marine rolling machines, which has the function of pre bending and higher working accuracy.

The upper roller of the level down type shipbuilding plate rolling machine rises and falls vertically and the lower rollers move horizontally. The upper and lower roller wheels are equipped with beam and support rolls, without tilting bearing body.

The unsymmetrical marine plate rolling machine can roll curved or conical work pieces with center angle below 180°. The length of work piece should be controlled between 8m and 21m, and the remaining straight edge is small.

How to operate the large plate bending rolls for ships safely? Please read on.

– The plate rolling machine for shipbuilding must be managed by a specially assigned person.

– The operator must know the structure, performance and usage of the machine.

– Only with the approval of the management personnel in charge can the workers carry out the operation.

– Please check whether the safety device is in good condition before starting the machine.

– During operation, it is strictly forbidden to put hands and feet on rollers, transmission parts and work pieces.

– When the work is interrupted, turn the clutch to neutral.

– Multi-person collaborative operations must be under the command of a dedicated person.

– No overload work.

– The lifting and overturning bearing of the upper roll, the toppling reset of the upper roll and the balance of the upper roll must be carried out after the main drive is shut down.

– It is forbidden to stack work pieces and sundries in the workplace.

– Keep the machine tool and site clean at all times.

– After finishing the work, cut off the power supply and lock the power box.

Marine plate bending roller is a large customized rolling equipment. Long supply period and high manufacturing price are the disadvantages of marine plate bending rolls. But the shipbuilding industry has to use it and cannot avoid these problems.

So as to avoid unnecessary rework and waste, customers should contact the manufacturer for customization according to the specific needs of shipbuilding. In the purchase, the user must be clear about the rolling plate parameters and processing requirements. Actively communicate with the manufacturer, so that you can buy a suitable high-quality marine bending machine.