With the development of society, the growth of labor costs, the improvement of product requirements, many companies have continuously improved their requirements for the performance and quality of production equipment.

As one of the important production equipment of forging machine tool and sheet metal industry, CNC plate bending machine is also constantly updated and developed. So, in recent years. We have launched an hybrid servo electric press brake energy-saving series.

Why is the hybrid press brake better? Why choose it?

Next, let’s talk about the upgrading of CNC plate bending machine and the advantages of hybrid electric servo press brake.

The update of the bending machine has gone through the following stages:

– Manual press brake: mechanical synchronization

– NC press brake for sale: torsion axis synchronization

– CNC press brake: electro-hydraulic synchronization

– Servo electric hybrid press brake: servo motor drive control

The previous bending machines were all torsion axis synchronous or valve-controlled. The Hybrid Servo CNC brake press is a real pump-controlled machinery. And the synchronization of the machine tools relies on pump control.

Human science and technology is more and more advanced, bending machine is also more and more advanced.

– From manual to numerical control to more advanced robot and automation

– From simple bending to complex machining

– From slow to fast to super high speed

– From low precision to high precision

– From noise to low mute quiet work

After years of research and development and improvement, as a new generation of hydraulic CNC bending machine, servo electric press brake is really a better choice for users.

Compared with previous generations of hydraulic bending machine, its advantages are very obvious. Next, we will analyze the outstanding advantages of hybrid electric press brake machine.

At present, the trend of sheet metal equipment industry in the future is to develop in the direction of environmental protection, energy saving, high efficiency, automation and unmanned.

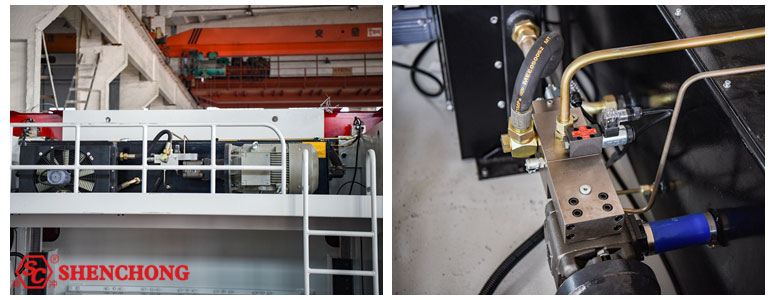

The WDK series servo electric hybrid CNC press brake produced by Wuxi Shenchong came into being, which perfectly embodies the superior performance of energy saving, high efficiency, automation and unmanned.

First of all, let’s take a look at the advantages in environmental protection and energy saving.

The WDK Series Hybrid Servo bending machine uses the world’s most advanced dual servo pump control system drive. We call it servo motor drive in the follow.

Servo motor replaces the traditional servo / proportional valve control technology. This drive solution saves more space, oil and energy than conventional hydraulic systems. The amount of hydraulic oil used is only about 1/3 to 1/5 of that of ordinary hydraulic systems.

WDK series servo motor driven hybrid CNC bending machine has the advantages of power consumption and energy efficiency.

Compared with the traditional bending system mode, its energy efficiency is very high. Because the system only uses the energy required for pressure at each stage.

Most of the pressure from bottlenecks will be reduced and offset. Therefore, the energy consumption can be increased by more than 75%. In standby mode, the energy consumption is the lowest, only about 5% of other systems.

WDK Series Servo Drive Hybrid CNC press brake for sale in high efficiency performance, the key is speed.

On the premise of ensuring the bending accuracy, its no-load and working speed can be increased by 15% – 25% compared with ordinary bending machine. The return speed can reach more than 1.5 times. This has greatly increased productivity.

And thanks to its excellent hydraulic system, we can control the oil temperature in a stable range after a long time of fast work. When the external ambient temperature is 38 ℃, the hydraulic oil temperature does not exceed 50 ℃.

It is suitable for factories in high temperature areas, such as South China, Southeast Asia, countries near the equator, etc. Users do not have to worry about the rise of oil temperature, but also improve the service life of bending equipment.

The servo electric motor press brake machine for sale can achieve automatic program calculation, laser automatic detection, automatic feedback and recognition of test results, automatic compensation, anti-collision control and so on.

Further more, it can also realize the real sense of unmanned operation. Its perfect cooperation with robots can realize a real unmanned factory. The staff only need to work on the computer system in the office, they can complete the whole process of ordering, blanking, production, transportation, and finished products, and they can continue to work for a long time.

Servo electric press brake machine not only has high precision, energy saving and low noise, but also is more stable and reliable with less oil consumption, which is conducive to the manufacture of large stroke and ultra-high speed bending machine.

In the coming year 2021, servo press brakes will become more and more popular. It’s worth trying!