Summary:

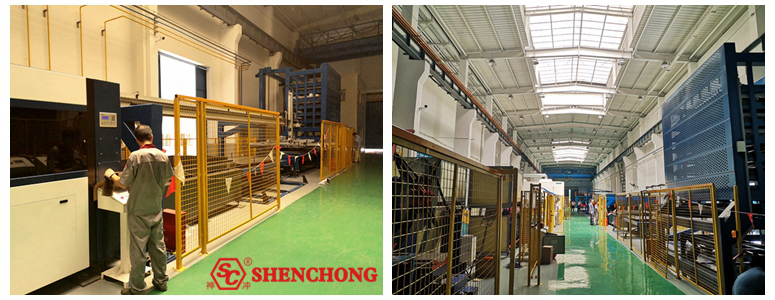

The flexible sheet metal intelligent workshop designed and manufactured by Shenchong for Zhenhua Heavy Industry was officially put into production! This is the first cable tray automatic production line in China.

At the end of 2019, Wuxi Shenchong undertook the project of sheet metal flexible automation production line of Zhenhua heavy industry.

At the beginning of 2020, Wuxi Shenchong began to build the cable tray automatic production line.

In the end of August, the flexible sheet metal intelligent workshop of Zhenhua Heavy Industry Co., Ltd. was started and successfully put into production.

The project contains:

It is a intelligent workshop for cable tray automatic production. This project includes sheet metal automatic production lines and related integrated components.

The flexible sheet metal intelligent workshop is divided into 15 areas:

East side – cable tray sheet metal flexible production line

West side – cable tray intelligent automatic production line

South side – automatic processing area

North side – artificial area and storage area

Purpose:

The project aims at automatic control, remote supervision, staff reduction and efficiency improvement, energy conservation and emission reduction, environmental impact assessment and safe operation.

This is the first project cultivated and implemented by Zhenhua Heavy Industry’s “Shuangchuang“( short for “mass entrepreneurship and innovation” ) platform.

The new trend of mass entrepreneurship and innovation

On September 18, 2018, the State Council of China issued the “Opinions on Promoting the High-quality Development of Innovation and Entrepreneurship and Creating an Upgraded Version of Shuangchuang “. On December 20, 2018, “ Shuangchuang ” was selected as the top ten economic buzzwords in 2018.

Among them, the cable tray intelligent automatic production line is the first in China. The production of the workshop is another important achievement of Zhenhua heavy industry in the field of intelligent manufacturing.

Features:

It is an intensive project of Zhenhua heavy industry and an intelligent comprehensive production project.

– Automatic control

– Remote supervision

– Reduce staff and increase efficiency

– Energy conservation and emission reduction

– Environmental impact assessment

– Safe operation

Advantages:

– The robot welding, robot splicing and robot grasping technologies introduced by the workshop are in the international leading level.

– The intelligent sheet metal storage system and automatic laser cutting linkage technology designed by Wuxi Shenchong are the new technologies that we have launched for the first time.

– The production line will apply for utility model patent in the future.

– Through this automatic sheet metal flexible production project, users can greatly save labor and time costs, and improve the efficiency of enterprises.

Shanghai Zhenhua Heavy Industries Co., Ltd. – ZPMC

Zhenhua is a heavy equipment manufacturer. Production and manufacture of large port containers and ore coal handling machinery, marine heavy industry, heavy special steel structure, marine transportation and installation.

Requirements:

They have higher requirements for the full automation and robotics of sheet metal processing, and the demand is also relatively large.

The main components, functions and parameters of automated production equipment need to meet the requirements of reliability and stability.

SHENCHONG Sheet Metal Automation Advantages:

– Shenchong flexible sheet metal intelligent workshop makes full use of the production management experience of Zhenhua heavy industry and optimizes the process flow.

– Give full play to the flexibility of each production unit and the convenience of processing program

– After the completion of the production line, the manufacturing cost will be reduced.

– Save labor cost and improve production efficiency every year.

– Compared with the traditional process, it uses more suitable tooling and reduces the investment of personnel and equipment.

– In the application of new materials, the workshop replaced the traditional galvanizing by material innovation to solve the market problems of environmental protection and insufficient supply.

– Handle the most challenging manufacturing tasks through the combination and integration of individual processing units.

At the beginning of 2020, Wuxi Shenchong began to manufacture automation equipment of Zhenhua heavy industry intelligent workshop and carried out on-site construction.

On August 26, Shenchong successfully completed the project of Zhenhua flexible sheet metal intelligent workshop, and held a ribbon cutting ceremony.

Wuxi Shenchong is very honored to undertake this project and complete it successfully. Our cooperation is very happy!

The project uses two flexible lines to complete the production. A series of processes from uncoiling to forming are integrated into the production system.

The annual output value of a single production line is expected to be 100 million Yuan. In the future, the workshop will continue to expand the production lines for junction box, expressway corrugated board, 5g equipment box, sheet metal batch, as well as the production line for customized products with high added value.

Wuxi Shenchong focuses on R & D, production and sales of sheet metal automation equipment and supporting products.

Relying on mechanical design, industrial software R & D advantages and more than ten years of manufacturing experience in CNC press brake and plate shearing machine industry, we can provide customers with a full range of automatic solutions and flexible production lines for sheet metal processing machines, including automatic loading and unloading machine, intelligent storage system, robot bending, etc.