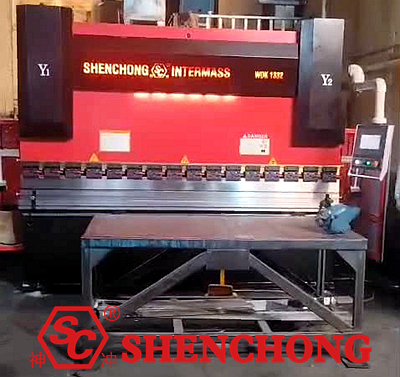

Radwan city metal, a customer of INTERMASS, the solo agent of Shenchong in Egypt, ordered four machines: WDK25040, WDK13032, WGK 30130, QC11K 6X3200 HIGH SPEED. This is the largest customer in Egypt. Now, the machines have been shipped to the customer's factory and installed and debugged.

The oil-electric hybrid servo WDK press brake machine is a bending equipment that combines hydraulic system and electric servo technology. It is widely used in sheet metal processing, machinery manufacturing and other fields. It combines the high strength of traditional hydraulic bending machine with the high precision, energy saving and environmental protection characteristics of servo electric technology, and has the following significant advantages and features:

The oil-electric hybrid structure allows the equipment to start the hydraulic system only when it needs to move, greatly reducing energy consumption.

Compared with traditional hydraulic presses, energy consumption can be reduced by 30%-70%, suitable for long-term operation.

The servo motor drive can accurately control the output of the oil pump to achieve fine adjustment of the bending angle and speed.

It has high repeat positioning accuracy and is suitable for products with high precision requirements.

The servo system responds quickly, runs more smoothly, and significantly improves work efficiency.

Start and stop quickly, reducing waiting time.

Almost no noise in standby mode, improving the working environment.

The oil pump only operates when moving, effectively reducing the overall noise level.

The oil circuit is simpler and the amount of hydraulic oil used is reduced (about 1/3 to 1/2 of traditional models).

The system generates less heat, reduces cooling requirements, and extends the service life of oil and components.

It can be equipped with a CNC system to realize functions such as multi-axis linkage and automatic angle compensation.

Easy to access industrial automation and intelligent manufacturing systems.

It can automatically adjust the pressure and speed according to the material, thickness and length of the workpiece.

When the motor stops, the system has no power output, reducing energy consumption and carbon emissions.

Easy to maintain and upgrade, the oil pump, motor or control system can be customized according to user needs.

It has multiple safety mechanisms such as overload protection, travel limit, photoelectric protection, etc.

Wuxi Shenchong Forging Machine Co., Ltd. has entered the sheet metal machinery market in Egypt and other Middle East and Africa for many years. We have been working stably with Egyptian distributors for many years. Every year, Shenchong exports dozens of bending machines and shearing machines to Egypt.

We have solid technical support and rich sales experience in Egypt. We can provide you with complete and timely pre-sales, in-sales and after-sales services. Welcome to inquire!