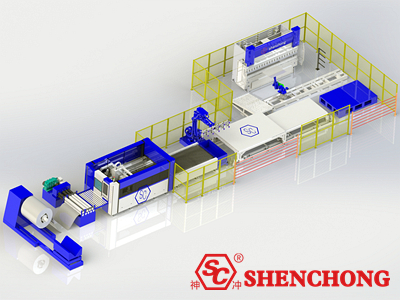

The sheet metal uncoiling and leveling production line is used to unwind cold-rolled steel coils, hot-rolled steel coils, stainless steel coils, and galvanized steel coils. After uncoiling and leveling, cut the cut-to-length plates of various specifications, suitable for industries such as stainless steel products, electrical appliances, vehicles and machinery manufacturing.

The CNC sheet material uncoiling, leveling and shearing production line has the function of automatic fixed-length cutting sheet material, which can uncoil, level, longitudinally cut and cut various coiled sheet materials into different specifications of sheets, and automatically stack them. tidy.

The use of this line can significantly improve production efficiency, reduce costs, ensure product quality, and greatly improve your company's market competitiveness. This line is mainly composed of feeding car, uncoiler, intermediate bridge, leveling machine, slitting machine, shearing machine, receiving table, hydraulic and pneumatic system, numerical control system and so on. Equipped with high-precision servo motor, reliable hydraulic system and high-tech programmable control system to ensure feeding and cutting.

The above is a summary of the functions and characteristics of the sheet metal uncoiling and leveling production line. Welcome to buy uncoiling leveling line products.

The uncoiling leveling machine is mainly composed of a frame, a coil support seat, a leveling roller, a driving device, and a leveling roller adjustment mechanism.

The frame is welded with high-strength steel, which has high stability and anti-vibration performance. The coil support seat is located above the machine frame and is used to support the weight of the coil and balance the tension of the coil. The leveling roller is composed of several rollers with different diameters, and the distance between the rollers can be adjusted to adapt to different thickness of the board.

The driving device is driven by a frequency conversion motor and a reducer, which can realize stepless speed regulation. The leveling roller adjustment mechanism can realize the position and angle adjustment of the leveling roller, so as to adapt to plates of different thicknesses.

The working principle of the uncoiling leveling machine is to place the coiled material on the coiled material support seat, start the driving device, and the coiled material starts to rotate and gradually unfolds. As the coil is unfolded, the leveling roller starts to work to level the plate. The leveling roller adjustment mechanism adjusts the position and angle of the leveling roller according to the thickness and hardness of the plate to ensure the best leveling effect. The leveled board is transported to the designated location for subsequent processing.

The decoiling leveler has the following advantages:

- It can realize the automatic unfolding and leveling of the coil and improve the production efficiency.

- The position and angle of the leveling roller can be adjusted according to the different thickness of the plate, and the adaptability is strong.

- Driven by variable frequency motor and reducer, it can realize stepless speed regulation and save energy.

- The frame is welded with high-strength steel, which has high stability and anti-vibration performance.

Sheet metal uncoiling and leveling machines are widely used in sheet metal processing industries, such as construction, automobiles, machinery, furniture, etc. Its usage scenarios include: unrolling the coiled material into a flat plate for use by shearing machines or punching machines. The unrolling the coiled material into a flat plate of a certain length and width for use in welding machines or production lines; unrolling and leveling the coiled material, and directly supplying it for downstream customers to use, etc.

The sheet metal uncoiling and leveling production line has the function of automatically cutting sheets to length. It can uncoil, level, slitting and cutting various coil materials into sheets of different specifications, and automatically stack them neatly. The use of this line can significantly improve production efficiency, reduce costs, ensure product quality, and greatly improve your company's market competitiveness. This line is mainly composed of feeding car, uncoiler, intermediate bridge, leveling machine, slitting machine, shearing machine, receiving table, hydraulic and pneumatic system, numerical control system and so on. Equipped with high-precision servo motor, reliable hydraulic system and high-tech programmable control system to ensure feeding and cutting.

It can effectively control the deviation of the coil, the fixed length is accurate, and the production efficiency is high. After the material head is sent to the leveling machine, it can automatically complete the whole process of uncoiling, leveling, cutting and blanking of the metal coil. It has the characteristics of high degree of automation, good leveling quality, high cutting precision, high production efficiency, stable and reliable performance, and convenient operation and maintenance. Slitting and shearing machine: hydraulically driven, cutting times 40 times/min.

- During the operation of the uncoiling leveling line, forward and reverse rotation cannot be selected, and the machine must be stopped first. After the emergency stop is turned on, forward and reverse rotation can be selected. When coiling materials, be careful not to touch the wires with the sheet material, so as not to scratch the wires.

- After using for a long time, check whether the screw nut is loose, and tighten it with a wrench if it is loose. If you encounter professional problems, you must ask a professional to deal with it.

- Pay attention to the maintenance of the leveling machine. Where there is a grease nipple, add butter once a month. Mainly the lubrication of the bearings! Pay attention to the cleanliness of the roller surface, and no welding slag, short sheets or other things are allowed to fall between the rollers, so as not to damage the leveling roller.

- When someone checks and repairs or refuels, it must be ensured that the power of the machine is completely cut off. When starting up, also pay attention to whether someone is too close to the machine.

- Establish safety awareness and pay attention to personal safety. All rotating parts of the leveling machine should not be in close contact!