Stacking crane is the abbreviation of stacking crane and is the characteristic symbol of sheet metal tower storage system. The sheet metal storage stacker is responsible for the functions of picking up, transporting, lifting, and discharging materials. Therefore, the function of the stacker directly determines the throughput efficiency of the warehousing system.

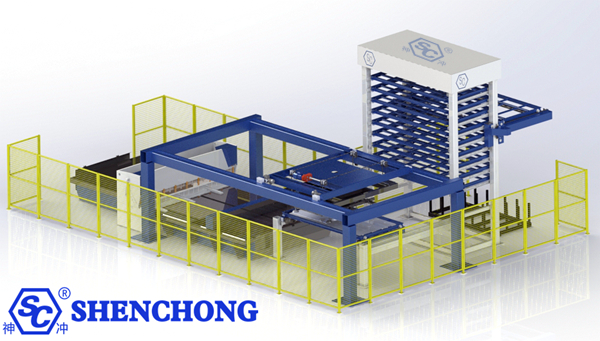

A stacker crane is an overhead automated loading and unloading system. It is mainly used for the handling, stacking and storage of materials in large storage spaces. It can realize efficient storage of sheets in a limited space and greatly improve the space utilization and work efficiency of the warehouse.

Early stackers hung a gantry (column) on the lifting trolley of a bridge crane, and used the up and down movement of the forks on the column and the rotation of the column to transport plates. They were usually called bridge stackers. Roadway stackers appeared in the United States around 1960.

The stacker is an important part of the automated three-dimensional warehouse. It has obvious advantages in overall shape, retrieval device, power control, protection measures, etc.

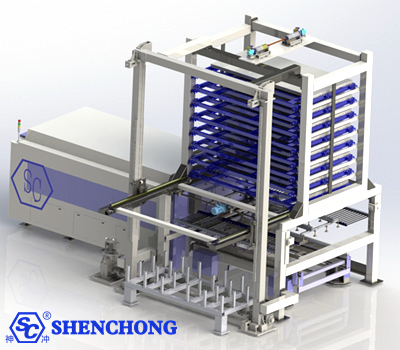

The automatic palletizer is the core equipment of the entire automated three-dimensional warehouse. Transporting sheets from one place to another is achieved through fully automatic operation. It consists of a frame, a horizontal traveling mechanism, a lifting mechanism, a cargo platform and an electrical control system.

Automatic stacker cranes are unmanned. The stacker cooperates online with the warehouse management system through the electrical control system. After receiving the operation instructions, the stacker can perform horizontal walking, vertical lifting, fork telescopic and lifting in the tunnel.

Complete the access operation of the cargo units in the designated cargo space, and transfer the cargo units with the conveying equipment or fixed transfer platforms located at the end of the lane to form a complete automated warehousing and logistics system. In this way, the access, transmission and sorting of metal sheets can be realized, and the movement of sheets in and out of the storage tower can be automatically carried out.

The speed or height of the stacker's access to goods can be adjusted. Through programming, the horizontal height of the stacker can be directly adjusted to increase the working speed.

The stacker crane is mainly composed of lower beam, cargo platform, fork mechanism, column, upper beam, horizontal operating mechanism, lifting mechanism, electric control cabinet, safety protection device and electrical control system.

The main structure of the sheet metal tower storage stacker crane is mainly composed of upper beams, columns, lower beams and control cabinet supports.

The upper and lower beams are made of steel plates and shaped steel welded into a box-shaped structure. Good cross-sectional performance. The running wheel axle holes on both sides of the lower beam are completed in one clamping process on the floor-standing boring and milling machine. This ensures the parallelism of the main and passive wheel axes, thus improving the smooth operation of the entire machine.

The column is made of square steel tubes, and two flat steel guide rails are welded on both sides of the square steel tube at a time. The guide rail surface is hardened. Good wear resistance.

Automatic welding technology with special devices is used during welding to effectively overcome the deformation of the overall structure. The upper beam is welded to the column. The columns and lower beams are positioned through flanges and connected with high-strength bolts. The entire main structure has the characteristics of light weight, torsion resistance, bending resistance, high stiffness and high strength.

The material holding mechanism is a component that moves vertically up and down through the power traction of the lifting mechanism. L-shaped structure welded by vertical and horizontal frames.

The vertical frame is used to install the lifting guide wheel and some safety protection devices. The horizontal frame is made of seamless steel pipes, which can fully meet the cargo loading requirements.

The horizontal running mechanism is composed of power drive and active and passive wheel sets, and is used for the operation of the entire equipment in the tunnel direction.

The lifting mechanism is composed of a drive motor, a drum, a sliding group and a wire rope, and is used to lift the cargo platform for vertical movement.

The fork telescopic mechanism is a mechanism composed of a power drive and an upper, middle and lower fork, which is used to store and retrieve goods perpendicular to the direction of the tunnel. The lower fork is fixed on the loading platform, and the three forks are linearly telescopic through chain transmission.

The stacker crane adopts three sets of guide wheel devices: upper and lower horizontal guide wheels and lifting guide wheels. The upper and lower horizontal guide wheels are installed on the upper and lower beams respectively to guide the stacker to move horizontally along the tunnel direction.

The lifting guide wheel is installed on the loading platform and moves up and down along the column guide rail to guide the vertical movement of the loading platform. At the same time, the load is supported through the guide wheel and transferred to the main structure.

The sheet metal automatic storage stacker uses advanced automated storage equipment to realize automated management of three-dimensional warehouse storage, and can automatically replenish cylinder cores and empty pallets to the conveyor line in a timely manner.

At the same time, the conveyor line can realize timely conveying of plates to the next station. The control adopts manual and automatic modes to more flexibly handle abnormal problems that occur during conveyance.

According to whether there are guide rails, they can be divided into rail stackers and railless stackers. Among them, the rail-mounted stacking crane refers to the stacking crane operating along the track in the tunnel. Trackless stacking crane is also called overhead forklift.

The main operating equipment used in automatic storage system are: tracked lane stacking cranes, trackless lane stacking cranes and ordinary forklifts.

According to different heights, they can be divided into low-rise, mid-rise and high-rise types. Among them, low-rise stacking cranes refer to lifting heights below 5m. Mainly used in split high-rise shelf warehouses and simple 3D warehouses.

Mid-level stacking crane refers to a lifting height between 5 and 15m. High-rise stacking crane refers to a lifting height of more than 15m, which is mainly used in one-piece high-rise shelf warehouses.

According to the driving mode, it can be divided into upper driving mode, lower driving mode and upper and lower driving mode.

According to the degree of automation, it can be divided into manual, semi-automatic and automatic stacking cranes.

Manual and semi-automatic stacking cranes with driver's cab. The sheet metal storage automatic stacking crane does not have a driver's cab and is controlled by an automatic control device, which can perform automatic addressing and automatic loading and unloading of metal sheets.

Stacking cranes can be divided into bridge stackers and tunnel stackers according to different uses.

Bridge stacker refers to a stacker that stacks sheets and is guided by suspended columns. A lane stacker refers to a stacker that has a metal structure supported by upper and lower supports. The stacker runs along the warehouse lane and loads items into pieces.

Stacking cranes can be classified according to different lifting heights and play a vital role in automated three-dimensional warehouses. The stackers in modern automated sheet metal storage system high warehousing efficiency through a series of advanced technologies and methods.

The advantages of the sheet metal tower storage stacker crane lie in its efficient warehousing efficiency, flexibility, versatility, and improvement in precision and accuracy. Stacker cranes can store more goods on a limited floor area, saving warehouse space and reducing the cost of leasing or building large warehouses. At the same time, the high accuracy and speed of the stacking robot make the storage and retrieval process of goods faster and more reliable, helping to reduce manual errors.

Compared with other palletizing equipment, the stacker has the following characteristics:

The stacking crane is a special equipment for sheet metal tower storage system. It has a high handling speed and cargo access speed, and can complete the warehouse entry and exit operations in a short time. The maximum operating speed of the stacking crane can reach 500m/min.

The stacking crane itself is small in size and can operate in tunnels with smaller widths. It is also suitable for high-rise warehouse operations and can improve warehouse utilization.

The stacking crane can be controlled remotely. The operation process does not require manual intervention. High degree of automation and easy management.

Stacking cranes have high reliability and good stability when working.

By optimizing the stacker's travel path, it reduces ineffective travel distance and time and improves operating efficiency.

The widespread application of high-tech achievements such as laser ranging, frequency conversion technology and high-performance PLC can promote the development of stacker technology. Improve operation accuracy, stability and work reliability.

The synergy between the stacker and the automated management system enables automatic and efficient entry and exit of designated metal sheets and improves the efficiency of warehousing operations.

In practical applications, stackers can be used in conjunction with automated conveying systems and advanced storage management software to achieve efficient warehousing and picking operations. For example, a small stacker sheet metal three-dimensional tower warehouse can store more sheets on a limited floor area. Save warehouse space and reduce the cost of renting or building a large warehouse.

With the continuous advancement and innovation of technology, stackers may have more new technologies and methods to improve efficiency in the future. For example, more advanced control algorithms, more precise positioning technology, and more flexible design solutions may become future development trends.

At the same time, with the development of artificial intelligence and Internet of Things technology, stackers may achieve a higher degree of automation and intelligence, further improving warehousing efficiency. In general, the application of modern automated sheet metal tower storage stackers in logistics and warehousing management is becoming more and more extensive. Its high efficiency, flexibility and space-saving characteristics give it broad prospects for future development.