The shearing machine anti-twist device system is an auxiliary device specially designed to solve the distortion caused by uneven force on the plate during the shearing process. It is usually integrated into the workbench or tool holder system of the CNC plate shearing machine, and exerts reverse restraint force on the plate through a specific mechanical structure or control method, thereby ensuring the shearing quality and the flatness of the plate.

A shearing machine anti-twist cutting system is an auxiliary device installed on a plate shearing machine, designed to reduce or eliminate the phenomenon of twisting, warping or deformation of the plate during the shearing process.

When the metal shear is working, it applies appropriate constraints or supports to the plate through a specific mechanical structure or auxiliary function, thereby improving the shearing quality and processing accuracy.

During the shearing process, the plate is prone to twisting or warping at the shearing edge due to uneven pressure distribution or asymmetric force on the blade. The anti-twist device works in the following ways:

During the shearing process, the anti-torsion device provides support to the non-shearing side of the plate through a mechanical arm, a support rod or an elastic device to prevent the plate from warping.

When the shear force acts on the plate, the anti-torsion device will apply a force opposite to the twisting direction to offset the deformation tendency of the plate.

The clamping mechanism equipped with the anti-torsion device will clamp the plate before shearing, fix its position and limit its freedom.

After the shearing is completed, the clamping mechanism is gradually released to ensure the flatness of the sheared edge.

Modern anti-torsion devices combine sensors and CNC systems to monitor the status of the plate in real time and automatically adjust the support force and reaction force according to the thickness, length and material of the plate.

Shearing Mchine Anti-twist Device Working Video:

Clamp the plate firmly before shearing to prevent displacement and warping caused by shear force.

Located on the non-working side of the shearing area, it provides support for the plate to prevent sagging.

Applies a reverse force to offset the twisting tendency generated during the shearing process.

Use springs or hydraulic mechanisms to absorb excess shear stress and reduce plate deformation.

The plate is fed into the shearing machine, the clamping mechanism of the anti-twist device clamps the plate, and the support device is adjusted to the appropriate position.

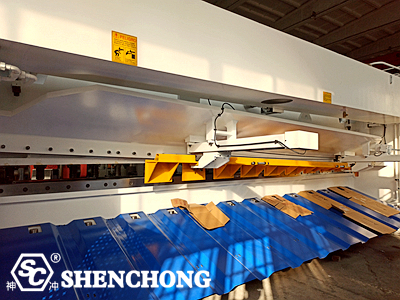

When the shearing machine blade begins to apply shearing force, the support structure of the anti-twist device and the anti-twist arm work synchronously to apply reverse force to offset the warping of the plate.

The anti-twist device gradually releases the clamping force to ensure that the plate leaves the shearing area smoothly and the shearing edge remains flat.

The shearing machine anti-twist device is a key auxiliary equipment in the hydraulic guillotine sheard. Its main function is to reduce or eliminate the distortion caused by uneven force on the plate during the shearing process. The following are the specific functions of the anti-twist device of the plate shearing:

When the shearing machine cuts thin plates or large-format plates, the plate is prone to distortion due to uneven force distribution. The anti-twist device effectively prevents this distortion by applying a reverse constraint force to the plate, ensuring that the plate is flat after shearing.

By reducing the deformation of the plate, the anti-twist device can significantly improve the accuracy and quality of shearing, ensure that the shearing edge is neat and smooth, and meet the requirements of subsequent processing.

Avoiding the trimming process caused by plate distortion, saving time and cost, and improving production efficiency.

The distortion of the plate may cause additional stress on the blade or mold of the shearing machine. The anti-twist device can reduce these stresses and extend the service life of the equipment and mold.

The modern shearing machine anti-twist device is flexibly designed and can be adjusted according to different materials and thicknesses to adapt to diverse processing needs.

The distortion of the plate may cause unexpected bounce or slip, increasing the risk of operation. The anti-twist device can reduce these risks and ensure the safety of operators.

In short, the anti-twist device of the shearing machine is an important component to ensure shearing accuracy, improve production efficiency and reduce costs, especially in the scene of processing thin plates or high precision requirements.

Prevent warping, cracking or twisting of the shearing edge, and ensure the flatness of the shearing surface.

Ensure the flatness and dimensional accuracy of the shearing edge.

It can effectively handle materials that are easy to deform, such as high-strength, stainless steel, and aluminum plates.

Reduce unqualified products caused by plate deformation and improve production efficiency.

Reduce stress concentration on the shearing machine blade and structure, and extend the service life of the equipment.

Thin plates are prone to warping during shearing, and the anti-torsion device can effectively prevent deformation.

For high-strength materials such as stainless steel and alloy steel, the anti-torsion device can reduce deformation after shearing.

Long plates are more likely to be twisted during shearing, and the anti-torsion device can ensure shearing accuracy.

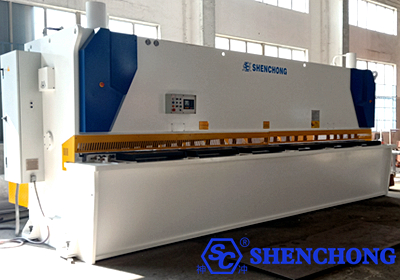

Case show:

Peru Guillotine Shear with Anti-Twist Device 13x6000 E21S

Shearing machine anti-twist device is an important auxiliary equipment to improve the processing accuracy and quality of the shearing machine, especially when processing thin plates, stainless steel or long plates. Through reasonable selection and adjustment, the deformation of the plate after shearing can be effectively reduced, and the production efficiency and product quality can be improved.