Elevator sheet metal flexible production line refers to the use of flexible manufacturing technology and automated equipment to efficiently and accurately produce elevator-related sheet metal parts.

Since the elevator manufacturing process involves a large amount of metal sheet processing, including door panels, frames, shells, brackets, etc., the quality, precision and production efficiency of sheet metal parts directly affect the overall performance and safety of the elevator. Through the flexible manufacturing system, it is possible to flexibly respond to different batches and diversified product requirements, greatly improving production efficiency and flexibility.

The acceleration of urbanization and the increase in high-rise buildings, coupled with updates and maintenance, have provided impetus for the stable growth of elevator demand. The continuous growth of market demand has also driven the sheet metal processing industry for components such as elevator cars, door panels, and control cabinets.

The elevator industry, as a typical representative of discrete manufacturing, highly relies on fine division of labor and collaboration in its production process. CNC, with its profound industry insights and technological innovation, has created a flexible production line for elevator door panels in the elevator industry, solving the pain points in traditional production models.

In the production process of sheet metal products, the wall and door panel, as key components, need to go through a series of complex and rigorous processes: from the initial stamping and cutting, to bending and forming, and then to the unique processing of the door panel, each step directly affects the final performance and appearance of the product.

Under the traditional production mode, these processes are often dispersed in different work areas and carried out using assembly line operations. This model has improved production efficiency to some extent, but there are also drawbacks.

The circulation of raw materials, semi-finished products, and finished products on the production line occupies a large amount of space, increasing warehousing and logistics costs

High human involvement and potential safety hazards, such as injury accidents caused by improper operation and scattered operations affecting product quality

The variety of products, large batch sizes, and frequent switching of production lines have reduced production efficiency and increased management difficulty and costs

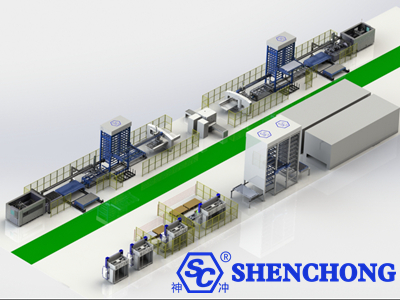

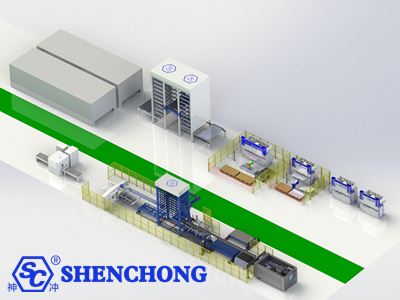

The CNC flexible processing production line integrates a three-dimensional sheet metal storage system, laser cutting, sheet metal bending, etc., realizing automatic loading of raw materials to the exchange table and automatic stacking of finished products to the pallet, digital operation, saving time and safe handling. Effectively solves the problem of wasting time on manual loading or driving, forklift loading, etc., greatly saving labor costs and reducing safety hazards.

The elevator sheet metal flexible production line is a highly automated and flexible production line designed for the elevator industry, aimed at improving the production efficiency, processing accuracy, and process flexibility of various sheet metal components for elevators. It can meet the needs of the elevator industry for personalized, customized, and mass production, reduce manual intervention, and improve the automation level and production capacity of the production line.

Flexible production lines can adapt to the processing of elevator sheet metal parts of different models and specifications, allowing for quick switching between different product types and meeting customized and personalized production needs.

With preset programs and modular equipment, the production line can quickly switch between different work tasks, reducing production preparation time. The flexible configuration of the equipment enables the production line to adjust flexibly according to needs, adapting to different production batches and production plans.

The elevator sheet metal flexible production line integrates an automated feeding system that can automatically feed materials into the work area and complete multiple process steps such as sheet metal positioning, clamping, cutting, and bending.

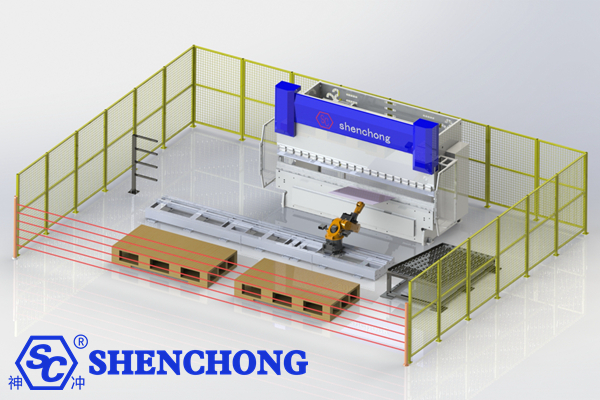

Automatic loading and unloading, bending, welding, etc. of sheet metal are carried out through industrial robots or collaborative robots (cobots), further reducing manual intervention.

The entire production line is operated through advanced digital control systems (such as CNC control, PLC control) to ensure the accuracy and consistency of each processing step.

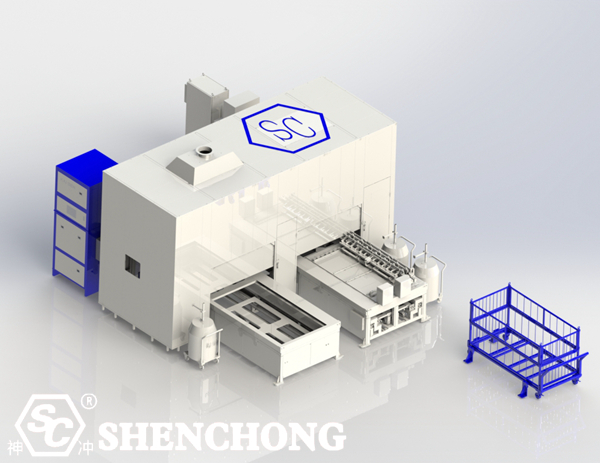

Flexible production lines often integrate equipment such as laser cutting machines, CNC punching machines, shearing machines, etc., which can achieve material cutting, stamping, carving and other processing operations.

Integrating automatic bending robots and laser welding equipment, it can accurately complete the bending and welding processes of various elevator components, improving production efficiency and product quality.

Production lines are usually equipped with high-precision visual inspection systems and force feedback systems, which can monitor the quality of components in real time during the production process, ensuring that the size, shape, and welding quality of each component meet the standards.

Through CNC systems and precision equipment, the production line can ensure high cutting and bending accuracy for each sheet metal part, minimizing errors and waste to the greatest extent possible.

All equipment and robots in the production line can maintain consistency in each production, ensuring stable product quality in batch production.

The flexible production line is equipped with a full process data monitoring system, which can track production progress, equipment status, processing parameters and other information in real time, providing accurate data support for production management personnel.

Through IoT technology, various devices on the production line can be remotely monitored and receive fault warnings. Pre detect potential equipment malfunctions and perform pre maintenance to reduce downtime and improve equipment efficiency.

Modern elevator sheet metal flexible production lines reduce energy consumption and improve energy utilization by optimizing equipment configuration. For example, designs such as servo motors, energy-saving lighting systems, and intelligent power management can effectively reduce overall energy consumption.

Through precise cutting and bending processes, minimize material waste, lower production costs, and contribute to environmental protection.

Automatic feeding equipment can accurately deliver sheet metal raw materials into the work area, reducing manual operations.

Equipped with automatic alignment, positioning, and clamping functions to ensure positioning accuracy during the machining process.

Laser cutting machines can efficiently and accurately cut sheet metal, especially suitable for complex shapes and high-precision processing requirements.

Laser cutting is not only suitable for common steel, but also for cutting various materials such as stainless steel and aluminum alloy.

CNC punching machines are used for processes such as punching, trimming, and stretching, and can efficiently and accurately process sheet metal.

CNC press brake can be used for precise bending of elevator sheet metal, ensuring that each bending angle and radius meet strict process requirements.

Efficient and high-precision press brakes can improve production efficiency while also reducing errors caused by manual operations.

Robots can bend metal sheets through computer control, which can improve the automation level of production lines.

The robot system, combined with visual recognition technology, can achieve precise operation of sheet metal parts, ensuring high quality and precision.

Automatic welding systems use precise control systems for welding, often equipped with laser welding, spot welding, or brazing techniques to ensure welding quality.

The welding process is crucial for the frame, car and other components of elevators, and automatic welding can provide consistency and efficient production capacity.

By using visual sensors and image processing technology, the size and shape of each sheet metal part are checked in real-time to ensure the quality of the parts.

Once non-conforming products are detected, the system will automatically sound an alarm and adjust processing parameters as needed.

By using automated carts or AGVs (Automated Guided Vehicles) to facilitate the flow of workpieces between various processes on the production line, efficient material handling is ensured.

Automated logistics systems not only improve production efficiency, but also reduce the risk of errors and injuries during manual handling.

Elevator car: making the frame, inner and outer shells, panels and other components of the elevator car.

Elevator door: Processing elevator door machine components, including door frames, door panels, etc.

Elevator counter weight: Production of relevant components for elevator counterweight systems.

Elevator control cabinet: Manufacturing of sheet metal shells, internal brackets, and other components of the elevator control cabinet.

Elevator guide rail: a bracket and frame structure used for manufacturing elevator guide rails.

Through flexible equipment configuration, the elevator sheet metal flexible production line can quickly switch production modes according to different needs, reduce line switching time, and adapt to the production needs of small batches and multiple varieties.

The fully automated control system ensures precision and consistency during the machining process, resulting in stable and high product quality.

By replacing manual operations with automated equipment and robots, a significant amount of labor costs have been saved, and errors and instability caused by manual operations can be reduced.

Capable of responding to rapidly changing market demands, achieving efficient customized production, and adapting to the rapidly changing design needs of the elevator industry.

The data collection and monitoring system of the production line can provide real-time feedback on production status, predict equipment maintenance requirements, optimize production processes, and further improve production efficiency and equipment utilization.

By precise cutting and bending, material waste is reduced, and the use of energy-saving equipment reduces overall energy consumption, meeting the requirements of modern manufacturing for environmental protection.

The elevator sheet metal flexible production line can significantly improve production efficiency, processing accuracy, and production flexibility through highly automated and flexible design. Adapting to different needs of elevator sheet metal components, especially in customized and small-scale production, has demonstrated significant advantages.

At the same time, it can also achieve automatic detection, data analysis, and maintenance through an integrated intelligent control system, ensuring the stability and continuity of the production process. These advantages make elevator sheet metal automatic production lines an important tool for elevator manufacturers to improve production capacity, reduce costs, and enhance competitiveness.