In the sheet metal industry, most companies are still engaged in traditional bending processes. In the production process, due to the variety of products, specifications, and small batches, multiple bending machines and a large number of skilled and experienced sheet metal bending operators are still required to complete the bending of the workpiece.

However, in actual work, there are the following problems:

First, because the operator works for a long time, the endurance is not continuous, resulting in inconsistent height positions of the work piece each time.

Second, the operator will not maintain stable work like a soft bending robot, so due to the manual influence, the size and bending accuracy of the bent work piece cannot be guaranteed, resulting in poor quality of the finished product.

Thirdly, 3-4 operators are generally required to complete the handling and operation of large work pieces, and the difficulty in recruiting and high cost is the enterprise.

The fourth is that operators have poor work safety, and there are greater safety hazards when working with work pieces, and work-related accidents are prone to occur.

Now, although the manufacturing and accuracy of sheet metal bending machines have been greatly improved compared with the past, there is still a big gap with the current requirements for intelligent manufacturing.

“Collaboration with networking” and other aspects also require joint innovation and development in the subdivision of sheet metal equipment manufacturing and the demand side. This innovation, development, promotion and application is another increase and liberation of productivity.

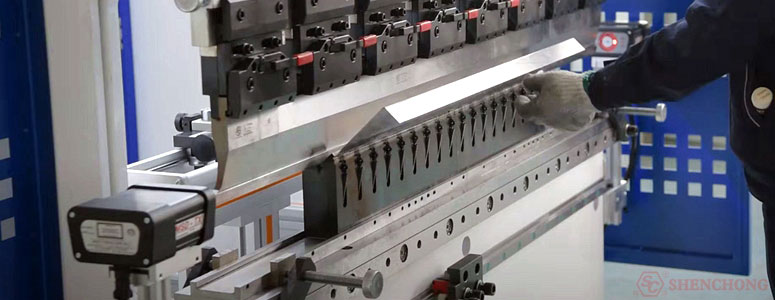

CNC Press Brake Bending Machine For Sale

The traditional bending of the sheet metal industry needs to solve the following problems:

It is impossible to realize multiple varieties, small batches, and fast switching.

The bending of high-precision workpieces in the sheet metal industry has low accuracy and unstable quality.

Sheet metal bending operators are scarce, and the labor intensity of workers is high.

Personnel costs, safety hazards, process layout, management and operation.

The above problems can be solved by choosing a set of intelligent soft robot bending cell, which includes:

CNC bending machine, 6-axis soft robot and seventh-axis guide rail, feeding station, magnetic sheet separation device, pre-alignment Positioning worktable, sheet material turning mechanism, feeding gripper, finished product stacking, mold library, offline programming software, parametric programming software, secondary developed bending software and extended services, etc.

The design of the soft bending unit aims to use the latest technology (software, hardware) to realize the intelligent product concept, so as to carry out real-time data exchange, real-time compensation and bending tracking follow-up during the production process.

The main problems solved and the results obtained are:

Solved the technical problems of customized sheet metal production, and solved the rapid switching production problems of multi-product, small-batch (5-10 pieces) and multi-variety parts in the elevator industry.

The problems of unstable product quality, low precision of parts and poor product consistency have been solved.

Solved the problems of low production efficiency, unreasonable production layout and process route.

Solve the problems of difficult recruitment, high labor cost, and high labor intensity of manual bending.

Improve the bending accuracy and automation, improve the enterprise’s intelligent manufacturing capabilities, and enhance the visual effect of customer visits.

In the soft robot bending cell, we applied parametric programming software, offline programming software and production management software. At the same time, we developed the bending follow-up, automatic die change, automatic gripper change, flexible palletizing, real-time compensation, and edge Edge seeking, flexible flip technology and bus control technology. Can greatly meet the technical and software requirements of various customers for sheet metal bending.