In recent years, with the large number of sheet metal stamping processing technology, bending work pieces have become the most important sheet metal processing methods. The precision of bending processing has become an important parameter for measuring the quality of work pieces. So what are the factors that affect the precision of sheet metal processing? How to guide to improve the precision of bending work pieces?

Precision sheet metal bending analysis involves the careful evaluation of various factors that affect the accuracy and quality of bends in sheet metal fabrication. In precision manufacturing, understanding and controlling these factors ensures that the final product meets the required specifications with minimal errors. Here’s an in-depth look at the key aspects of precision sheet metal bending analysis.

In the bending processing of high-precision work pieces, the deficiency of the machine tool is a factor that must be considered.

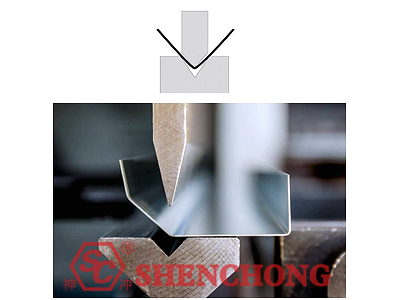

Affected by the structure of the bending machine, the overall work range presents a tiny arc, which causes the slider to move in the horizontal direction. There is a certain gap between the record value and the actual displacement.

The value of the middle part is large, which leads to changes in the angle in the length direction during bending processing, which causes the problem of excessive intermediate angle and affects the precision of bending processing.

Reduce the deformation of the machine tool itself.

Set the oblique structure above the model, and use the oblique structure to compensate the precision loss caused by the deformed deformation.

In the actual processing process, the degree of deformation of the material and nature of the work piece is different. If you want to achieve higher precision of deformation compensation, you must conduct multiple tests to obtain the best form of compensation. After that Perform massive production to ensure the processing precision of the work piece.

You may also want to know: Sheet Metal Forming: What Factors Cause Workpiece Deformation?

When processing sheet metal processing, the sheet to be processed is regarded as a homogeneous body, with the same physical properties and thickness.

However, in fact, there are differences in a certain thickness and unevenness of metal sheet, which affects the bending precision of the metal sheet. This factors are most obvious when bending in the gap, which will cause the actual displacement direction of the upper slider to cause offset and the direction of the travel direction, resulting in a certain angle error.

Select the metal sheet with evenly materials.

Uneven material is an important factor that affects the bending precision of the work piece, causing uncertainty of the rebound volume of bending processing.

In response to this problem, you should start with the choice of metal sheet and try to choose high -quality metal sheet with evenly materials as the material for bending processing.

At the same time, it should be started from the manufacturing of the metal sheet to achieve the improvement of the quality of the metal sheet with the help of advanced metallurgical and forging processes, and improve the general quality of the metal sheet.

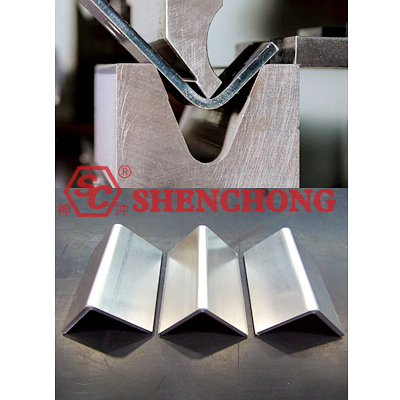

As we all know, the metal sheet has rigidity. After the mechanical effect of sheet metal processing is evacuated, a certain range will be rebounded, resulting in the angle of curve below the design value.

In response to this problem, when processing of sheet metals, "over-bend" is required, leaving a certain amount of rebound.

However, affected by the uncertainty of the material unevenness and the uncertainty of the work piece, the rebound volume is difficult to accurately estimate, showing disorderly discrete distribution features, which affects the precision of the final bending angle.

Improve the overall quality of the metal sheet, try to select the high-quality plate with a uniform material as the material of the bending processing of the work piece to improve the general quality of the plate.

When designing the work piece, people mainly design the size of the work piece, and calculate the size of the work piece development material on the basis of this.

However, the size of the work piece formed after bending processing of different materials and shapes is different.

In addition, work pieces need to be tailored with the help of shear machines, and its cutting also has certain errors.

The above two aspects lead to a certain exit of the actual size and expected value of the work piece expansion, which affects the final work piece size and precision.

Improve the size and precision of the work piece. During the processing process, the improvement of the size and precision of work pieces should be carried out from the following two aspects:

The first is to accurately calculate the length of the expanded material, consider the deviation value of the work piece size, incorporate it into the calculation of the unfolding material, and select the intermediate value as the calculation value. At the same time, the public difference should be reasonably distributed.

The second is to improve the processing precision of work piece development materials and reduce cutting errors.

There are three main reasons for the forming size of the work piece to do not match the drawings: the cut size error, the bending positioning is inaccurate, and the accumulation of errors with multiple bending accumulation.

Adjust the bending factor, re -calculate the expansion of the size; adjust the positioning; select a reasonable positioning benchmark to eliminate the cumulative error.

If the cutting size error and cumulative curvature error are within the allowable range, the formation size can be guaranteed first, and the error can accumulate the non -installation edge that has no effect on the work piece.

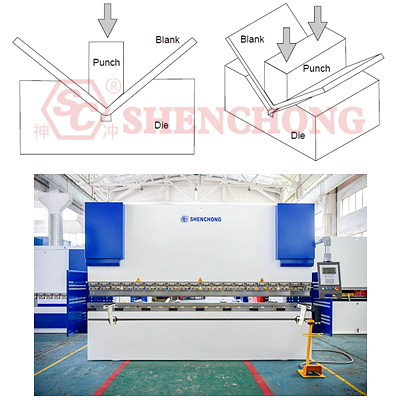

The bending angle of the work piece is too large or too small, which can easily lead to the deviation of the bending angle. It is mainly caused by the improper lower -die V port, improper setting of the punch rebound compensation parameter, and the pressure of the press brake.

Refer to the bending die platform to select the appropriate downward die, adjust the compensation value and the pressure of the press brake.

Sheet metal bending processing is an important method for sheet metal processing. The processing precision of processing to a large extent determines the manufacturing quality of the processing and manufacturing industry. Strategy, improve the processing precision of work pieces, and meet the development needs of processing manufacturing.

Click here to know more about Metal Sheet Bending Process