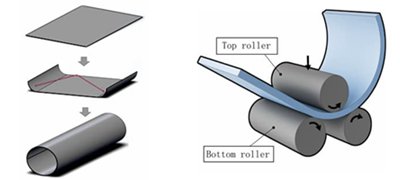

Plate rolling machine equipment, also known as bending rollers, plate bending machine, roll bending machine, is a mechanical equipment used to roll and bend metal plates (such as steel plates, stainless steel plates, aluminum plates, etc.). Its main function is to roll flat metal into a round, conical or other specific shape. It is widely used in steel, shipbuilding, machinery, construction, papermaking, electricity, aerospace and other industries.

The plate rolling machine equipment rotates and applies pressure to gradually roll the metal plate along the roller of the machine to finally reach the desired shape and size. The application scenarios of the plate rolling machine are very wide. From simple round and tubular parts to complex conical, rectangular and other special shapes of metal plates, the plate rolling machine can complete them efficiently.

The plate rolling equipment in the workshop can make sections of sheet metal into round, or conical shapes. We call this process plate rolling, bending roll or plate bending.

Plate rolling is one of the most important manufacturing processes in the world.

The plate rolling machine is a kind of equipment that uses work rollers to make sheet metal round processing and forming.

We also call it the plate bending roller, a kind of machine tool for continuous point metal sheet bending.

In the sheet metal industry, it is a piece of very important manufacturing equipment. We can use it to form cylindrical parts, conical parts and other parts with different arc shapes.

Specifications and model parameters mainly include:

– Maximum thickness of rolling plate (mm)

– Maximum width of the rolling plate (mm)

– Yield limit of the plate (MPA)

– Rolling speed (M / min)

– Minimum diameter of full load rolling plate (mm)

– Diameter of upper roller (mm)

– Diameter of lower roller (mm)

– Center distance between two rollers (mm)

– Main motor power (kW)

– Machine weight (ton)

– Overall dimension (length × width × height) (mm)

The plate rolling machinery makes the material in the free state to conduct three-point continuous rolling, resulting in the plastic deformation process.

The rolling process of the bending roll is continuous elastic bending with a certain stretch.

Its advantages are as follows:

– Smaller rebound

– Precise shaping

– High bending roll quality

– High efficiency

– Low cost of use

– Roller Bending requires less force than press brake bending

– Price of the rolling machine is lower than that of the bender

– Equipped with the auxiliary device to roll taper parts

– Wide application: realize the rolling of plate, pipe, and profile

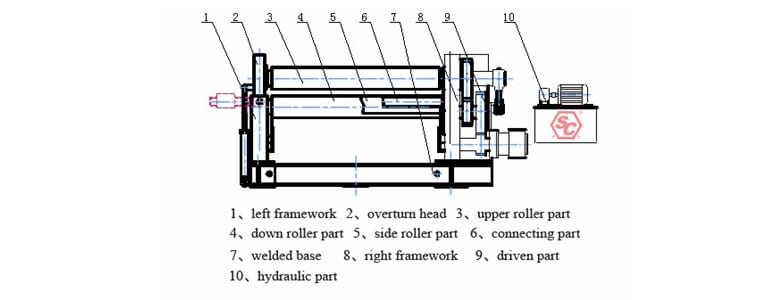

The sheet metal plate rolling machine is composed of upper and bottom rollers, moving device, supporting roller, transmission device, turning device, working system, control system, and so on.

Top roller

The upper roller device is mainly composed of the main oil cylinder, bearings, and upper roll. The upper roll is an important part of the bending machine.

It is usually made of 42CrMo and tempered after rough machining. Quenching and tempering hardness HB 230 ~ 290.

Bottom roller

The bottom roller device is made of the lower roll, bearing seat, gear, sliding bearing, etc.

It is suitable for normal temperature conditions and low-speed heavy-duty sites.

The lower roller is made of high quality carbon steel. They are processed by rough machining and quenching and tempering. Quenching and tempering hardness HB230 ~ 290.

Supporting roller

The supporting roller device is composed of supporting roll, wedge mechanism and adjusting hand wheel. The roller is made of 45# steel and has been quenched and tempered.

There is a group of support rolls. Users can adjust them up and down according to the load of rolled plate specifications.

The support roller is used to support the middle part of the lower roll to improve the rigidity of the lower roll. So as to improve the forming accuracy of the workpiece.

In the metal rolling process, work rolls are affected by extreme operating conditions. It includes huge forces, bending moments, thermal stresses, and wear.

The manufacturer must consider the strength, stiffness, and wear resistance of the material when making the rollers.

The frame is composed of the machine body, slide plate and shaft sleeve.

The frame is welded and annealed. It is used to install the main hydraulic cylinder and drive the upper roller parts to move horizontally.

The rolling machine base is box welded structure, quenched and stress relieved.

For the installation of various components. Put the frame, reducer, motor and other devices on it, and then form a whole.

The main drive device is consist of main motor, brake, gear, reducer, bearing, etc.

The system can rotate forward and reverse to provide power. The torque is transmitted to the lower roll through the main reducer. The output gear and the lower roll gear make the lower roll rotate. It relies on friction to drive the plate to feed and complete the rolling work.

The movement device is powered by a motor. Through the reducer, gear, worm, screw rod and nut mechanism to drive the movement of rollers.

The horizontal moving device is powered by the horizontal moving motor.

It drives the frame and the upper roll parts to move horizontally through the worm drive mechanism and the screw drive mechanism to realize the pre bending of the workpiece.

The overturning device includes sliding block, oil cylinder, etc.

It is installed on one side of the overturning frame used for overturning and recovering.

The function of the turning device is to facilitate the product taken out along the axial direction of the roller.

It is composed of beam, support plate and rod.

It is used to press the end of the upper roll to keep the balance of the upper roll after the overturning frame overturned, so as to facilitate the unloading of the workpiece.

There are two working systems of plate bending rolls: mechanical transmission system and hydraulic transmission system.

– The Low-end or manual plate rolling machine usually adopts mechanical transmission.

– The High-end or NC/CNC plate rolling machine always uses hydraulic transmission.

Mechanical System

The mechanical system plate rolling machine adopts mechanical transmission.

Mechanical transmission of the rolling machine has a history of many years.

Due to its simple structure, reliable performance and low cost, mechanical transmission is still widely used in small and medium-sized plate rolling machines.

However, the low speed and high torque rolling machine is not suitable.

If mechanical transmission system is used, in this case:

– Large transmission system

– High motor power

– The power grid fluctuates greatly during startup

Therefore, hydraulic transmission is becoming more and more popular.

Hydraulic System

The hydraulic system plate rolling machine adopts hydraulic transmission.

All movements are controlled by a hydraulic system station. The whole system has a hydraulic pump station, solenoid valve, superposition valve, oil cylinder and pipeline. All valves and accessories are connected by manifold block.

In order to ensure the effective operation of the hydraulic system, the hydraulic station is equipped with a protection device.

Advantages of hydraulic drive:

– Low energy consumption

– Convenient to adjust the working pressure and rolling speed suitable for different working conditions

– Easy to realize automatic control

Comparison of the two:

The hydraulic bending roller is an upgraded product of a mechanical roller.

The hydraulic rolling can increase the thickness and width of the rolling circle and complete the defect that mechanical rolling cannot roll thick plate.

It is more convenient for the original plate blanking, docking, correction and other complex processes.

Mechanical Hydraulic Combined System

In recent years, some manufacturers use the hydraulic drive for the movement of the work rolls, but the main drive is still mechanical transmission.

We call this type of plate rolling machine a mechanical hydraulic combined rolling machine. This design is also very common now.

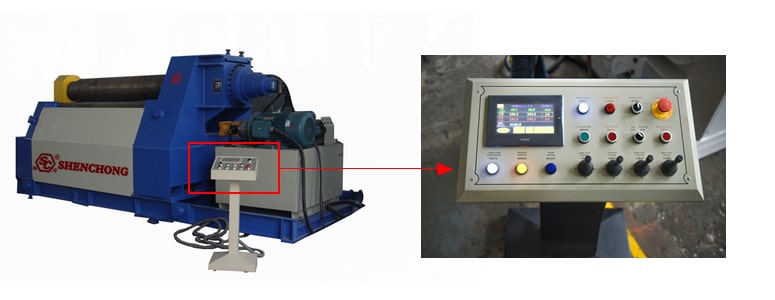

The plate rolling machine has manual type, numerical control type and automatic type.

The power of the rolling machine is relatively large, so most manufacturers use AC motor as the driving control part.

Manual type

In this way, the machining efficiency is low, and the machining accuracy is difficult to ensure.

It has not been able to meet the requirements of the modern market for product processing efficiency and quality

Therefore, it is necessary to carry out a simple numerical control transformation of the plate rolling machine to meet the requirements of the market for the processing efficiency and accuracy.

Numerical control type

With the development of industrial automation, automation system and automation equipment based on PLC, MCU and PC are more and more popular. The corresponding man-machine interface also came into being and developed synchronously.

The rolling machine is a typical example of mechatronics. Its design is based on the understanding of the mechanical structure, the user requirements for a detailed functional analysis.

The corresponding control scheme is adopted to meet the requirements of users. It is a new type of computer technology, automatic control technology and communication technology.

The practical automatic control device is widely used in the field of rolling machine control.

It has the characteristics of good reliability, high stability, strong real-time processing ability, flexible and convenient use, and easy programming.

The rolling machine is a forging machine, designed by the principle of rolling and bending.

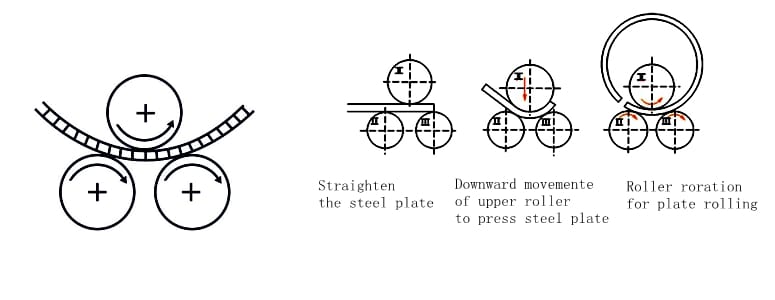

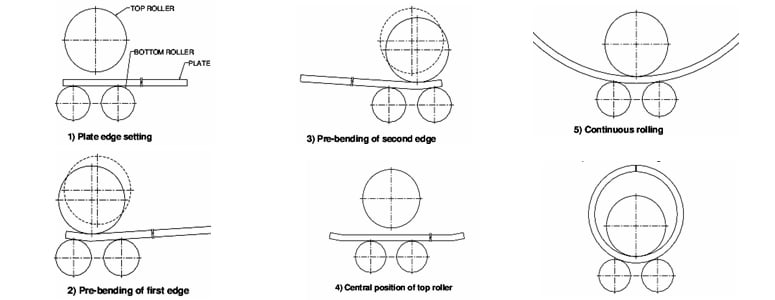

Working roll move through the action of hydraulic pressure, mechanical force and other external force to make the plate rolling or bending.

According to the principle of three-point round forming, the bending machine uses the relative position change and rotation motion to make the plate produce continuous plastic deformation. So as to obtain the workpiece with a predetermined shape.

During the rolling operation, the geometry of the sheet changes, but its volume remains almost constant.

The motion form of the sheet metal rollers can be divided into two forms: the main motion and the auxiliary movement.

– Main motion

The rotation and bending of the upper and lower rollers of the plate bending roller. The main motion completes the processing task.

– Auxiliary motion

The movement of loading, unloading, lifting and overturning of the upper roller in the rolling process.

The upper working roll is moving by the driving device. Use the friction between the roller and the plate to drive the other two bottom rollers, thus rolling the iron plate into a cylinder.

Users can change the distance between the roller to adjust the thickness and diameter of the workpiece.

We divide the rolling process roughly into the following three steps.

Remaining straight edge:

In the rolling plate, there is a length at both ends of the plate. It does not bend because it does not touch the upper roll. We call it the remaining straight edge.

Symmetrical rolling:

The remaining straight edge is about half of the center distance of the lower roller.

At the same time, it is also related to plate thickness.

Asymmetric rolling:

The remaining straight edge is about one sixth to one tenth of the symmetrical bending.

It is difficult to eliminate the remaining straight edges completely when straightening.

But it will easily lead to quality and equipment accidents. Therefore, we need to pre bend the sheet metal.

If there is no pre-bending, workers can also use the mold to correct after the final rolling.

When we put the sheet into the bending rolls, we should align it in order to prevent the workpiece from skewing.

Thus, the generatrix of the workpiece is parallel to the roller to ensure the quality of rolling.

The purpose of rolling correction is to make the curvature of the whole circle uniform as much as possible, so as to improve the product quality.

Correct rolling steps:

– Loading

According to the experience or calculation, adjust the roller to the required maximum correction curvature position.

– Rounding

Under the corrected curvature, the roller rolls twice. Focus on rolling the welded part to make the curvature of the whole circle consistent.

– Unloading

Gradually discharge the load so that the workpiece rolls several times under the gradually reduced corrective load.

Konw more about Working Principle & Rolling Processes of Hydraulic Plate Rolling Machine

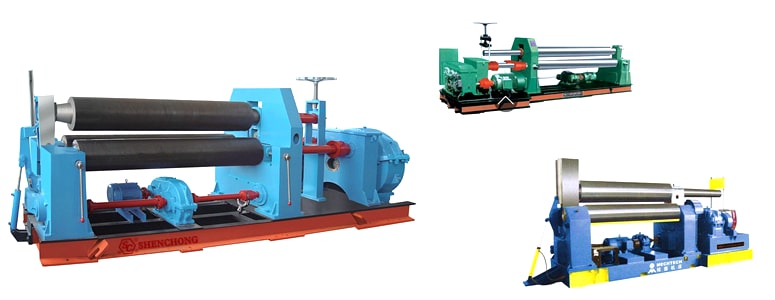

The sheet metal rolling machine is one of the eight major forging machines. Its development has been experienced from mechanical to hydraulic and then to CNC.

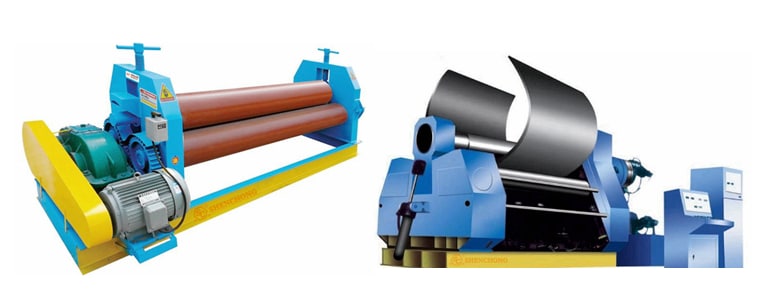

At present, the famous plate rolling machine manufacturers mainly include PROMAUDAVI, MG, FACCIN in Italy, SCHAFER in Germany, HUGH SMITH in the UK, ROUNDO in Sweden, KURI-MOTO in Japan and SHENCHONG in China, etc.

There is a growing demand for the 3 roll plate rolling machines to process large thick plates, high strength plates and composite plates.

The large 4 roll plate rolling machine has the characteristics of good forming precision and short remaining straight edge, which makes it become the development direction.

The small CNC plate bending machine for processing extra long thin plate is the development demand of the oil tank truck industry.

Providing customers with complete sets of equipment not only to provide a single coil machine is also a future development direction.

Another important development direction is to form a flexible production line processing unit based on CNC automatic plate rolling machine.

– From the production

The development trend of the plate rolling machine is to the economy and adaptability.

– From the direction

It is also developing in the direction of improving the utilization efficiency of the driving device.

Plate automatic feeding technology is specially used to solve the feeding problem of the plate rolling machine.

Therefore, this must fully meet the basic requirements of the feeding action of the bending rolls and have the following characteristics.

Automatic center alignment

The roll forming of sheet metal is mainly completed by the roll of the machine.

When the plate enters the bending rollers, we must ensure that the front edge of the plate is in contact with the outer circumference of the roller at the same time.

In this way, the rolled parts have high precision and high quality.

The automatic center alignment operation of the automatic feeding equipment is mainly completed by the center alignment rod driven by the servo motor.

Then the pushing device put the plate to the feeding place, waiting for the plate to be rolled.

Flexibility

Considering the particularity of sheet shape, we mainly use the vacuum sucker pick-up device to transport the plate.

The rolling machine can roll plates of different sizes. So the sucker position in the picking device of the automatic feeding equipment needs to have the appropriate adjustment function. In order to be suitable for the plate transportation of various specifications and sizes.

Fast and Stable

In order to meet the working cycle of the plate rolling machine and the safety of the handling process, the plate handling process with automatic feeding should have better rapidity and stability. So as to prevent over shock and vibration during transportation.

The automatic feeding equipment of the plate rolling machine is mainly composed of the plate trolley, the actuator, the plate conveying mechanism and the auxiliary mechanism.

The trolley is used to place the plate to be rolled.

The main function of the actuator is to transport the plate to be rolled on the trolley to the feeding platform.

The handling operation of plate mainly adopts the manipulator and vacuum chuck picking device.

In the industrial automation system, we often need to pick up and carry the workpiece. Vacuum chuck is widely used as a sucker manipulator.

– Efficient

– Small size

– Light weight

– Simple structure

– Easy to manufacture and install

– Removable……

Now, the frame of the rolling machine is made of forging and welding instead of the original casting.

In addition to the development of the high-power rolling machine, it also attaches importance to automation and unmanned. This development is characterized by high and new technology.

With the wide application of computer technology, sensor technology, automatic monitoring, remote control and centralized control have been developed. It enables the operator to have a clear view of the working face of the bending machine on the computer screen, and can adjust it according to the needs at any time.

The bending roll process is a deformation operation, which can make the plate have a certain curvature. It has the function of rolling O-shaped, U-shaped and multi-stage R-shaped plates.

The plate rolling manufacturing can produce a wide range of different products. All metal or steel forming for cylindrical, almost need to use the bending rollers for rolling.

Rolling machine application fields:

- Structures

- Wind Towers

Wind Power Towers Manufacturing And Wind Turbines Structure

- Off-Shore Platforms

- Aerospace Aircraft

- Shipyard

- Energy Industry

- Earth Moving Machines

- Truck Containers

- Boilers

Guide Of Boiler Manufacturing, Applications And Types

- Pressure Vessels

Manufacturing Of Pressure Vessels: Rolling And Welding

- Heat Exchangers……

With the rotation movement and position change of work rolls with different shapes, the plate bending machine can process oval, arc and cylindrical parts.

By properly adjusting the relative distance between the upper and lower rollers, the user can bend the plate to any value with a radius not less than the radius of the upper roller.

The width of the rolled workpiece can be as much as a few meters or narrower than one thousandth of an inch. Manufacturers have also created a wide range of thickness rolling machine.

The working capacity of the rolling machine refers to:

The ability of a smaller diameter of the bending roll when the sheet rolled with a larger thickness and width according to the specified yield limit under the cold state.

The maximum working capacity is determined by the following factors:

– Maximum rolling thickness (pre-bending thickness)

– Maximum roll width

– Material of rolled plate

– Minimum drum diameter at maximum size

These four parameters determine the maximum working capacity of the plate rolling machine.

In the work, the conversion of these four parameters is the conversion relationship of the working capacity of bending rolls. The rolling machine produced by the professional manufacturers will have the manual provided to the user for more reasonable operation.

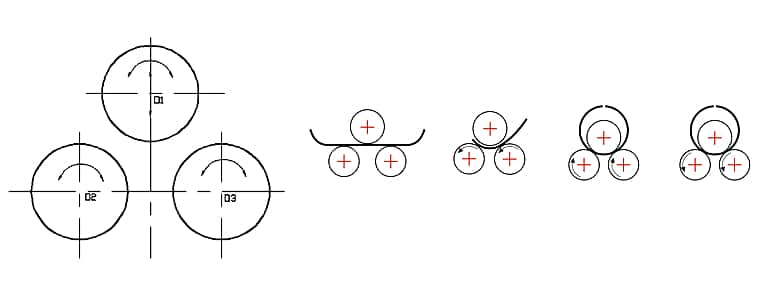

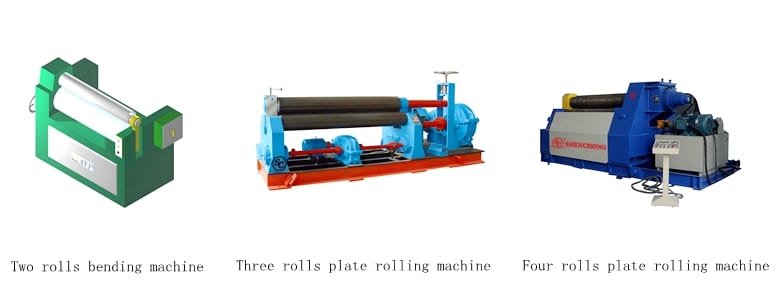

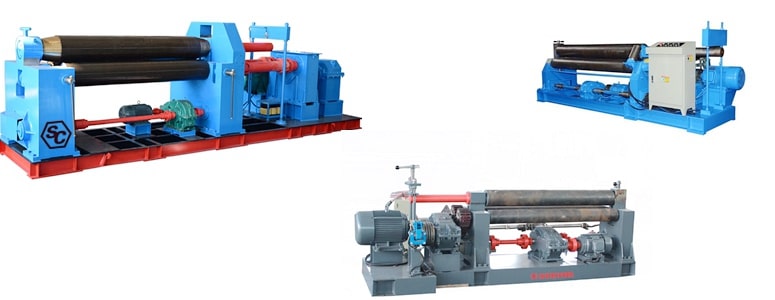

As for the classification of the plate bending machine, we can divide it according to the configuration of work rolls and the number of rolls.

Generally, we can divide into 3 types:

– Two roll bending machine

– Three roller plate rolling machine

– Four roller plate rolling machine

2 roll bending machine

The two-roll models are all manual hand plate rolling machines.

This kind of old plate rolling machine is unable to meet the production standards and requirements of large factories. They are slowly being phased out.

3 and 4 roll bending machine

Now, the mainstream rolling machine on the market is three roller and four roller model.

Next, we will give you a detailed analysis of the three roll plate bending machine and the four roll plate bending machine.

The three roll bending machine has the most structural forms. Compared with the four roll bending machine, the structure is simpler and the cost performance is high. So the three roller model is very common.

3 plate rolling machines can be divided into mechanical and hydraulic, symmetrical and asymmetric.

The plate rolling machine with 3 rolls is compact in structure, easy to operate and maintain.

We will introduce you to the design and performance features of popular and hot-selling types.

This type can be made into large, middle and small size according to the needs of customers

Structural form:

– Vertical movement of the upper working roll

Power: hydraulic cylinder. Function: apply pressure to the plate to make it bend.

– Horizontal movement of the lower working roll

Power: motor. Function: adjust the horizontal distance between the upper and lower work rolls.

Thus, the upper and lower rollers are symmetrically arranged.

Realize the pre-bending of the end of the plate and reduce the length of the straight side.

– Rotation of bottom work roll

Power: electromotor. Function: provide torque for the rolled plate.

– Overturning and reset of the opening device

Power: hydraulic cylinder. Function: unload the finished workpiece.

Design and Performance:

– The upper roll is drum shaped.

You can adjust support roll in the lower part of the bottom roller to do an ideal rolling process from thick plate to thin plate.

– Unique bending process. High precision end pre bending. Digital control of the bending process

– With the help of an auxiliary cone cylinder device, can roll the cone easily.

– Whole base. Simple foundation. Convenient in the workplace.

The structure is three roller symmetrical type.

The upper roller moves vertically in the symmetrical position of the two lower rollers.

The two lower rollers are the main driving rollers to rotate. The output gear of the reducer is meshed with the lower roller to provide torque for the rolled plate.

According to the transmission, the 3-Roller Symmetry Plate Rolling Machine can be divided into mechanical and hydraulic.

– Mechanical:

The W11 mechanical 3-roller symmetrical plate rolling machine obtains the transmission power through the screw nut and worm gear.

We can install the profile molds at one end of the roller of the mechanical symmetrical plate rolling machine to facilitate the processing of the profile.

– Hydraulic:

W11Y hydraulic 3-roller symmetrical plate rolling machine obtains transmission power through the hydraulic oil in the hydraulic cylinder acting on the piston.

Structural form:

Both the upper and lower rollers are the main driving rolls.

The vertical lifting of the lower roller is convenient for clamping the plate.

The lower roll gear is meshed with the upper roll gear to drive the upper roll to rotate.

The side roll makes a linear inclined lifting movement to complete the pre bending and rolling of the plate.

Performance and Advantages:

– It has pre bending function

– Once forming improves work efficiency

– Make small diameter cylinder

Structural form:

– The three rollers are all main drive rolls and with the same diameter.

– The position of the upper roller is fixed.

– The two lower rollers move up and down in an arc around a fixed rotating center.

– Also, they can move up and down together or separately.

– The rotation and lifting movement of the main rolls are all hydraulic transmission.

– The lifting movement can be displayed on the screen.

Performance and Advantages:

– Introduction of Italian technology.

– movable operation table, convenient and fast.

– The touch screen displays the displacement of the two lower rollers with high rolling precision.

– Two lower rollers arc up and down, and the leverage increases the forming force.

– Good feeding and rolling function for any thickness plate

– In the rolling process, the plate can always be clamped without sliding and deviation.

– Three rollers can be close to achieving small diameter rolling and rounding.

– Have cone rolling device.

Performance and Advantages:

– The three rollers of the lever down rolling machines are all active rolls.

– The lifting of the upper roll and the horizontal movement of the lower roll are driven by hydraulic pressure.

– Synchronization of bottom mounted main cylinder controlled by computer.

– Compact, small size and high precision.

– Especially suitable for cold and hot rolls.

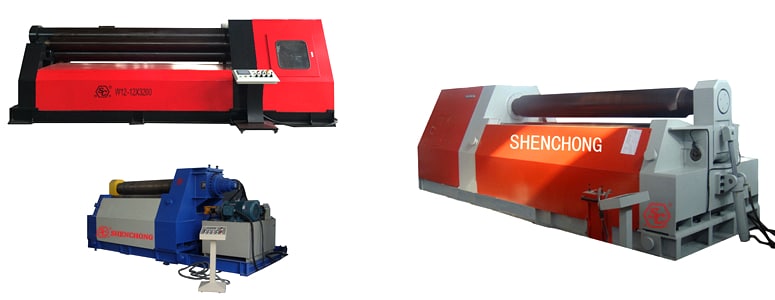

The hydraulic plate rolling machine 4 roll can be used for pre bending and rolling of cylinder workpiece in pressure vessel, machinery, water and electricity, construction, and other industries.

At the same time, it has the function of circle and leveling.

Structure form:

– The upper roller is driven by the hydraulic motor.

– The friction force between the steel plate and the roller drives the lower roll and the side roll to rotate, providing torque for the rolling.

– Bottom roll, side roll, and overturning frame are all driven by hydraulic pressure.

– Lower roll up and down vertically, while the side roll rises and falls in an arc.

– Pre-bending holds the steel plate by raising the lower roll.

– Side roll tilts upward to realize the sheet end pre bending.

Performance and Advantages:

– Convenient and simple operation.

– Diversified rolling methods.

– CNC numerical control, digital display of each work roll displacement.

– High precision and good roundness.

– Full hydraulic drive, high efficiency, and energy saving.

– Drive power equal to 60% of traditional.

– Once roll round, productivity is 50% – 80% higher than three roll convolution.

– Material aligning is convenient and accurate, avoid the phenomenon of the wrong edge.

– With a cone device for easy roll-up cones.

– Permanent lubrication technology: the bearing does not need oil within service life.

– The board is always pressed tightly by the upper and lower rollers in the rolling process without slipping.

– 4 roller plate rolling machine for sale can roll the workpiece with a diameter of 1.1 times of the upper roller.

– When the end of the plate is pre-bended, the straight edge length is smaller than that of other types of bending roll machines.

– Easy to add handling device, feeding device, and supporting device.

Symmetrical up roller adjust series:

– The upper work roll moves vertically.

– The position of the two work rolls is relatively unchanged.

Upper roll universal series:

– The upper work roll moves vertically and horizontally.

– The relative position of the two lower rollers remains unchanged.

With upper beam series:

– Arrange a press roll on the upper roll.

– Install the pressure roller at the lower part of the upper beam.

– Increase the rigidity of the upper beam and the diameter of the upper roller is smaller.

– Suitable to roll the parts with a small radius of rounded corners.

This series of plate rolling machines are specially used for shipbuilding.

The marine rolling machine is mainly used for rolling the arc plate of the ship shell and pressing the groove bulkhead.

– According to the requirements of customers, we can design symmetric and asymmetric marine plate bending machine 3 rolls.

– The upper part of the upper roll has a rigid beam.

– There are several groups of idlers between the upper roll and the girder and the lower part of the lower roll, to improve the rigidity of the upper and lower rollers.

– Three roller full drive.

Know more about The Ultimate Guide For Shipbuilding Rolling Machine

First of all, be clear about your own needs and requirements

– Parameters of plate: material, thickness, and width.

– Processing requirements: work piece drawings, shape, roll diameter, precision, roundness, error, angle, opening size, and some special requirements.

You should tell the information correctly to the manufacturers or suppliers.

In this way, they can recommend you the most suitable model and the clearest quotation.

Secondly, have a certain understanding of plate bending rolls

– Hydraulic or mechanical

– 2 roll, 3, roll or 4 roll

– Manual, NC or CNC

You should think about the 3 following questions or consult a professional.

Only with a basic understanding of the rolling machine, you can better communicate with the plate roller manufacturer and purchase the best equipment.

Some useful tips:

– The 3 roller plate rolling machine suitable for steel or metal sheet from 6mm to 100mm thickness.

– A three-roller bending machine costs less than a four-roll bending machine.

– 4 roller plate bending rolls have higher precision, efficiency and capacity.

– Compared with the symmetric 3-roller rolling machine:

CNC 4-roller rolling machine can directly bend the end of the sheet without any other equipment. And the remaining straight side is smaller.

– Compared with the asymmetrical 3-roller rolling machine:

The four-roller rolling machine can roll the plate without turning. Simple process and convenient operation.

Improve efficiency, ensure the quality of the work piece, and reduce the labor intensity of the workers.

Select reliable manufacturers and discuss details

At present, there are many brands of plate rolling machines, so consumers should be careful when choosing the machine. We can select the rolling machine manufacturers from the following aspects.

Quality

The quality of rolling machines is the most important.

To assess the performance and quality of the machine, we can judge it from the perspectives of frame strength, appearance, application scope, rolling accuracy and speed, special functions, control difficulty, operation stability, failure rate, repair rate, using life, and so on.

The configuration of some important parts is closely related to the durability of the plate bending roller machine

Some typical problems, you can ask the manufacturers. For example:

– What’s the weight of this machine?

– What brand are the reducer and motor used?

– The roll is hollow or solid?

Through some special questions, you can better judge the quality of the machine. To know whether it is really worth the price.

Price

There is a saying in China that cheap no good goods, good goods are not cheap! Closely related to quality is the price.

The good-quality plate rolling machine’s price is higher. However, the situation of high prices and low allocation is not excluded.

Please make sure to shop around. Make inquiries from different manufacturers and compare them more.

Not the most expensive is the best. Not the cheapest is the most suitable.

You should choose the most cost-effective one according to your standards and requirements.

Buy the best that your money and venue allow.

Service

Pre-sales, sale, and after-sales, please take all these 3 aspects of the service into account.

Pre-sale and sale service:

– When you ask the company for inquiries, are they enthusiastic and active?

– Whether their team is professional and thoughtful when discussing technical issues?

You can read their official website first and search the customers’ comments online.

If you can, please go to their production factory for on-site visits.

An on-site visit can directly judge whether this rolling machine manufacturer is professional and capable.

Face to face communication and discussion can better reflect the service level of a company.

After-sale service:

Before you decide to cooperate with a company, be sure to ask about their after-sales service

For example:

– How long is the warranty period?

– How to charge for site debugging?

– How to deal with the maintenance?

– Is there a training service for operations?

– Is there a local department that can provide after-sales service?

You can also check some comments and feedback online. The quality and service of manufacturers with a good reputation will also be better.

Useful Tips

– Buy the most suitable, not the most expensive.

– Buy the most cost-effective, not the cheapest.

– Buy a brand new sheet metal roller instead of a second-hand one.

– Buy a plate rolling machine produced by a professional manufacturer instead of “three no products”.

Top 10 professional plate rolling machine manufacturers:

PROMAU DAVI, FACCIN, AMADA, SHENCHONG, HAEUSLER, ROUNDO, HUGH SMITH, DURMA, PIOCT, KUMLA.

The most important point: cooperation with professional plate rolling machine manufacturers will get better quality assurance and service.

Click Here: The World’s Top 8 Plate Rolling Machine Manufacturers

Generally, the working efficiency and failure rate of mechanical equipment are closely related to the operators.

As operators of plate rolling machines, they should know more about relevant knowledge to effectively avoid some human errors or accidents.

Let’s learn about safety requirements and correct operation.

– The rolling machine must be managed by a specially assigned person.

– Operators must be familiar with the machine structure and performance.

– Start operation after the approval of the responsible management personnel.

– Before operation, check the safety devices carefully.

– There must be a special person to direct the multi person cooperative operation.

– Avoid the clothing corner involved in the roller during the operation.

– During operation, hands and feet are not allowed to enter between roller and transmission parts.

– Pay attention to that the operator can only stand on both sides of the workpiece. This is the most reasonable and safe location.

– During work, don’t stand on the finished products.

– It is also prohibited to stand on unprocessed workpieces.

– No overload work!

– A certain allowance must be reserved at the end of machining.

– After the work is interrupted, please put the clutch in neutral.

– Carry out the tilting, resetting, and balancing of the upper roll’s lifting and overturning bearing after the main drive stops.

– Forbidden to pile up workpieces and sundries in the workplace.

– Keep the workshop clean and tidy all the time.

– At the end of the work, should cut off the power supply and lock the power box.

In terms of the CNC forging industry, it is necessary to establish strict technical operation rules.

It can not only greatly improve the production efficiency, but also avoid the safety production accidents caused by improper operation. And perfect and orderly operation regulations can effectively extend the service life of the machines.

Preparations:

– Please tidy up the working environment first. Maintain a good working environment.

– Wear the required labor protection appliances, such as safety helmet, work clothes, etc.

– Keep clean and tidy to avoid getting clothes into the rollers.

– Make sure all the machine components are normal and reliable.

– Adjust the distance between work rolls in strict accordance with the plate thickness.

– Don’t overload!

– Strictly forbidden to roll the workpiece beyond the specified range of mechanical properties.

During operation:

– The signal should be clear. Appoint a person to direct the work.

– Only after the workpiece is in a stable position, you can turn on the power to start operation.

– Do not place hands on rolled steel plates.

– After the workpiece enters the roller, it is necessary to prevent hands and clothes from being drawn into the rolling machine.

– To adjust or measure the size and roundness, you must stop the machine. It is forbidden to carry out it when the machine is running.

– When measuring the roundness of dimensions, don’t stand on the cylinder rolled.

– The rolling not round enough sheet: when rolling to the end of the plate, reserve a certain amount of allowance. Prevent the workpiece from falling down and hurting people.

– For some parts that are difficult to process, such as thicker or larger diameter, higher hardness or strength of raw materials, etc. Users should work through a small number of operations and multiple processing to achieve the desired results.

– For some parts with a small diameter, users should place them in the middle of the roll for rolling operation.

Stop working:

– If there is abnormal sound in the operation of the bending machine, you should stop the machine tools immediately, and check & repaired.

– Turn off the switch and cut off the power supply.

– After shutdown, put the workpiece in the designated place.

– Pay attention to the regular cleaning of the rolling components, especially the connection.

– The assembly of the rolling machine must follow the principle: from inside to outside, from bottom to top.

– During assembly, please give priority to centralized handling of assembly work using the same tools or in the same place.

– Carry out the assembly process in strict accordance with the design drawings. We should strictly control the size and specifications.

In the actual work, also need to consider the influence of the following factors.

Correct the curvature radius of the workpiece appropriately:

– Springback

Due to the existence of elastic deformation, spring back occurs after the sheet is rolled and the radius of curvature will increase.

Therefore, when rolling, we need to increase the down pressure and reduction.

– Hardening

Because of the cold plastic deformation, the strength and hardness of the plate increase, while the plasticity and toughness decrease.

This requires increasing the reduction of force and amount.

– Yield limit of plate

Let’s take the ordinary plate rolling machine as an example.

The working capacity of the rolling machine is designed according to the yield limit of 235mpa.

If the material changes and the yield limit increases, the reduction force and reduction amount should be increased.

– There are many factors that also affect the radius of curvature. We should make some corrections based on the actual situation.

With the analysis and study of the pressure force and the pressure amount, we can also control the actual rolling process.

These provide a reference for workers to operate and a theoretical basis for automatic control.

Press Brake Bending Machine Latest Buying Guide

The correct use and proper maintenance can greatly extend the using life of plate bending roller. At the same time, it can reduce the cost of repairs.

The main points of bending roll machine maintenance:

– Make sure that rolling machines work under normal operation and regular lubrication

– The electrical system should be properly grounded.

– Electrical components should be regularly maintained and disassembled.

– Replace the damaged and failure components in time.

– During operation, you should pay attention to the temperature of each part.

– Formulate a regular inspection and maintenance system.

– If any parts are damaged, repair them in time. All wearing parts shall be replaced when they are excessively worn or lose their original performance.

– It is not allowed to stack anything randomly in the working area.

– Clean the oxide layer on the surface of the machine in time.

– Strictly comply with the lubrication system.

– According to the regulations in the lubrication diagram of the machine, add lubricating oil to the lubrication points of each oil cup and manual lubrication as required.

Reasonable lubrication for the machine transmission parts and sliding surfaces can reduce power consumption and improve the machine service life.

So it is necessary to choose the right lubricant and grease lubrication system.

According to the working condition, we adopt box-type lubrication and regular lubrication.

– Each slider guide surface lubricated by hand gun, grease once per shift.

– Slider bearing between rollers lubricated by one-time lubrication.

– Main drive gear speed reducer of bottom rollers and transfer-case adopted box-type lubrication.

The lubrication system of the rolling machine is very important in the whole machine tool. Its design, debugging and maintenance play an important role in improving the machining accuracy and prolonging the service life of the plate rolling machine tool.

– Each roller slider bearing, slider guide board adopted lithium-based grease.

– Speed reducer adopted N220# industrial gear oil.

– Rack slider guide surfaces available by hand gun once per shift.

– Before each work shift, must lubricate to every lubrication point

– Check whether the speed reducer lubricant oil at a predetermined position.

– The main drive speed reducer after the first working 150 hours, should change lubricant once.

– After that, change lubricant after working 1500 hours or once a year.

– You should clean the entire lubrication system after the first 150 working hours, after that at least once cleaning per year.

– If the machine is in the long-term continuous full load, you should clean the plate rolling machine once half a year.

In the rolling plate process, we often encounter the situation that the cylinder produced appears big in the middle and small in the two ends.

We usually call this phenomenon barrel (drum) deformation.

For medium and thin plates with the same material properties:

The larger the plate width (the size along the length direction of the equipment) is, the smaller the diameter of the rolled cylinder is, and the easier the deformation is.

When the width of the plate exceeds 5m (in this case, the flat plate is welded and then rolled), the barrel deformation will be obvious.

Deformation brings great inconvenience to welding or internal assembly.

If the deformation is too large, we must shape the workpiece to meet the requirements of the following process.

But this kind of deformation is very difficult.

In order to reduce the amount of shaping as much as possible, it is necessary to analyze the causes of the deformation. So that roll the qualified cylinder at one time. And take appropriate measures to prevent or remedy and eliminate deformation.

During the working process of the plate rolling machine, the upper roll presses downward and the rollers on both sides rotate to make the plate continuously bend around the upper roll. So as to achieve the purpose of rolling the required radius of the cylinder.

According to the structure of the plate bending machine, we can analyze the stress of each roller in the working process as a beam.

Generally speaking, the upper roll is thicker with better rigidity. The lower roll is slightly thinner and less rigid than the upper roll.

If the downward pressure of the upper roll is too high and the rigidity of the side roll is insufficient, the roller will deform.

– Especially for the rolling machine with long roll shaft (e.g. more than 5 m):

When the pressing and bending force are close to the limited capacity of the equipment, the roll shaft is more likely to be deformed.

This makes the gap between the upper and lower rollers inconsistent along the length direction.

The gap between the two ends is too small. As a result, the two ends of the roller shaft have a large pressing force on the plate and a small pressing force in the middle.

That is to say, the stress and strain of each point along the length direction of the roll shaft on the same layer of the metal plate are not uniform. The bending radius of the middle part is enlarged to form a barrel shape.

– For medium and thin plates with the same material properties:

When the thickness of the plate is the same as the diameter of the rolled cylinder, the larger the plate width is or the smaller the diameter, the greater the required pressing and bending force, the greater the deflection caused by the roll shaft deformation.

Therefore, the greater the difference of stress on each point along the length direction, the more obvious the barrel deformation is.

If the width of the plate exceeds 5 m and the diameter of the rolled cylinder is small, the barrel deformation will be obvious.

From the above analysis, we can see that:

The barrel deformation is mainly caused by the insufficient rigidity of the roller shaft.

That makes the uneven force on each point on the same level as the plate along the roller shaft.

For rolling out the ideal cylinder, it is very important to keep the gap between the upper and lower rollers uniform and to ensure the same pressing force and bending force on the plate.

According to the specific situation, the following measures you can take:

1) Choose a plate rolling machine with enough rigid roller shaft

In this way, the roll shaft will not deform even when rolling the largest sheet metal.

However, the rigidity of the roller shaft is related to its section modulus. It is limited by equipment structure and other factors. It is impossible for us to make the roller shaft very thick.

2) Arc correction

In this case, the rolling machine manufacturer should consider to design each roller as slightly curved according to the length of the rolling machine, the performance of the rolling material, and the thickness of the plate. That is, to correct the roller shaft by the arc. However, this only applies to a certain range of sheet thickness.

Purpose of arc correction:

In the process of plate rolling, when the upper and lower rollers are subjected to bending deformation, the part of the plate clamped by them tends to be straight.

That is to ensure that the gap between the upper and lower rollers of the clamping plate is consistent. So that the stress on each point of the plate along the length direction of the roller shaft is uniform.

The size of the arc shall be calculated carefully by experienced professional technicians according to the material and applicable plate thickness range.

3) Use auxiliary support roller in the middle of the lower roll to enhance the rigidity. Or roller arc correction and auxiliary support roller both.

The number of auxiliary support rollers is set according to the length of the equipment.

At present, most of the famous plate rolling machine manufacturers will adopt the method of roll shaft arc correction combined with adding auxiliary support to design and manufacture long bending rollers.

However, the correction methods adopted by different manufacturers are slightly different according to their own experience.

In this way, when rolling cylinders of different sizes, we can adjust the upward pressure of the auxiliary support wheel properly. So the lower roller has an upward reverse deformation in the rolling process.

After the upper roller presses downward, the reverse deformation of the lower roll will be eliminated.

The upper and lower rollers fit well with the material to ensure that the stress and deformation of each point on the same layer of the plate are consistent. So as to eliminate barrel deformation and roll up the qualified cylinder.

This method can adapt to a wider range of sheet metal than simple arc correction. The effect is better as well.

4) For the plate bending roll with neither arc correction of roller shaft nor auxiliary support roller of lower roll:

– When rolling the cylinder in sections, try not to roll the cylinder to the limit.

Then, the rigidity of each roll shaft of the metal roller can bear the pressing and bending force without deformation. This is the most basic and the easiest to do.

– In the case of not affecting the pressing and rolling of the plate, appropriately reduce the pressure of the upper roller.

Reduce the amount of pressing each time. This method makes the gap between the upper and lower rollers consistent. In this way, the barrel deformation of the formed cylinder can be reduced.

– Pad two gaskets between the sheet metal and the upper roll for auxiliary adjustment.

Therefore, the compression and bending force of the plate along the length direction of the roller shaft are basically the same.

– Appropriate modification of the equipment.

In order to enhance the rigidity of the lower roller, add auxiliary supporting rollers in the middle of the lower roller. The specific method has been mentioned above.

Wear is a process in which the material is gradually lost due to the mechanical action of friction.

It will cause the size of the object to decrease gradually in the direction perpendicular to the friction surface.

Local mechanical damage is formed on the contact surface under high stress. The damage form is affected by the surrounding environment.

Under certain friction conditions, the wear process can be divided into three stages: run-in, stable wear and severe wear.

Run-in Stage

– Run-in is an unstable phase of wear.

– It takes up a small proportion of the whole working time and has a high wear rate.

– But it decreases with working hours.

Stable Wear Stage

– The time of the stable wear stage is the longest.

– It is characterized by slow wear and stable wear rate.

Severe Ware Stage

– In the severe wear stage, the wear rate increases sharply.

– For the roller of the plate rolling machine, it means that the stress concentration is serious.

– It leads to the roller fracture easily.

Run-in of trial operation

For the plate bending machine, the idling running in of the machine is of great significance to the efficiency and service life of the machine.

Running in can form elastic contact conditions on the machine surface.

Thus, it can provide a minimum friction rate and a stable friction value.

Stable roughness

The important rule of run-in is stable roughness.

It is not related to the original roughness, but depends on the wear conditions.

This is a medium and long-term running in for the work.

The run-in results between the rolling machine and plate are affected by material, load, speed, mechanical and physical properties.

However, as long as the pressure does not exceed the critical value, it is better to keep elastic contact.

Initial fracture of roller

1) For the upper roll

Causes:

– The problem must be that the pressure of the upper roller is too large

– The strength safety factor of the roller is insufficient.

Measures:

– At this time, it is necessary to consider the design to have a relative swing space.

– Carry out the rolling process step by step and at a reasonable time.

2) For the lower roll

Causes:

– The problem is that there is no initial running-in stage.

– The torque of the lower roller increases a lot of additional wear torque than the normal running in.

– So the comprehensive stress increases and the failure occurs.

Measures:

– The lower roller should be thickened properly and idled in advance to prevent the trouble.

Mid-term fracture of roller

Compared with other stages, this kind of roller fracture is more common.

1) There are mainly two kinds of faults in this period.

Causes:

– It will be a welding gap after the plate welded.

– Analysis of welds from a more microscopic perspective:

It is a straight edge, not an arc edge.

It's a thick edge, not a thin edge.

It's rough, not smooth.

– Generally speaking, it not only increases the friction between the upper and lower rollers.

– And the torque of the lower roller is also increased.

Measures:

– We should polish the weld before rolling round, not too thick.

– Secondly, rolling must be carried out step by step.

– These need not only theoretical calculation, but also experienced guidance.

2) Wear causes fracture.

Causes:

– The smaller the diameter of the bending plate, the greater the contact force and tangential stress.

– Wear causes excessive stress concentration on the roller, which may cause fracture at any time.

Measures:

– If the rolling done one by one, the bending torque will be reduced. So the tangential stress will be reduced and the lower roll will be safe.

– In this case, it should be noted that the rolling process should be divided into several main passes, so that the pressure will not exceed the critical value.

– Eliminate the hard spots and impurities for rolled plates to avoid scratches and scratches.

– Improve the surface hardness of the roller.

Later fracture of roller

Causes:

– If the design and operation are in accordance with the specification, after the fatigue stress of the roller reaches a certain number of cycles, stress concentration will form, leading to fatigue fractures.

– With the increase of the overload tangential stress, the fracture accelerate.

Measures:

– Within the technical level, we should try our best to improve the hardness of work rolls.

– Promote its wear resistance and fatigue resistance.

– Similarly, reducing the contact stress will increase the life expectancy of the roller.

The rolling process is generally cold rolling. When the coil is cold rolled, the spring back is obvious.

Therefore, for thin, large diameter, high alloy material cylinder, we must apply a certain amount of over-volume.

Roll the specified cylinder a little smaller. After the amount of over-rolling reached, you should rewind several times at this curvature.

According to the mechanics of materials, the spring back of the rolled sheet depends on the elastic modulus, yield limit, drum diameter, and plate thickness.

The materials, processes, molds, and workpieces shape complexity in bending parts are different. The spring back of parts after forming is different.

The main factors are as follows:

– Mechanical properties of materials

– Relative bending roll radius

– Bending roll angle

– Shape of curved parts

– Mold size

– Compensation method

Control the geometric shape and size of the rolling according to the spring back trend and the size of the bending part. Thus, the spring back of the work piece can be compensated after bending roll.

– Stretch bending roll method

Apply a pull force while sheet bent. In this way, the upward pressure area of the plate can be transformed into a pull zone.

The distribution of stress and strain tends to be consistent to reduce the amount of spring back.

– Pressure correction method

After the sheet metal bonded with the roller, additional pressure applied to correct the bending deformation zone.

– Increase bending roll

According to the calculation and experience, increase the roundness of the roll by 2% to 5% to meet the need for spring back.

With the progress of technology, the performance of the bending roller is more and more stable. The processing speed is increasing gradually. The oil cylinder provides running power for the rolling machine.

If there is a problem with the oil cylinder, the machine is difficult to use normally.

The following is to introduce the common problems of the oil cylinder of plate bending rolls.

– Insufficient oil supply of hydraulic pump

Due to the wear of internal parts of the hydraulic pump, the volumetric efficiency of the pump is reduced.

As a result, the cylinder load increases, the pressure increases, and the leakage increases.

The increase of leakage caused the speed of the pump to the oil cylinder could not reach the specified value.

– Problems with hydraulic cylinder layout

The end face of the piston is close to the end face of the cylinder.

When starting, the bearing area of the piston is not enough, so it can not push the load.

Therefore, the speed of the rolling machine oil cylinder is slowed down.

It is worth mentioning that the occurrence of this situation is often caused by the lack of meticulous preparation before working.

In any case, we should not neglect the maintenance of mechanical equipment, so as to avoid accidents.

– Overflow valve failure

If the relief valve spool is stuck in the open position, a large amount of oil will flow back to the tank from the relief valve.

This will make the flow into the cylinder too large and not enough speed.

– The accumulator has small volume or low charging pressure

– Connection between hydraulic cylinder and load

When the speed of the cylinder is not accurate, it will cause the cylinder to move slowly.

Then, the flow into the cylinder is too large and the speed is not enough.

The common problems of the oil cylinder of plate rolling machines are roughly divided into the above several kinds.

When there is a problem with the oil cylinder of the equipment, you must analyze it according to the situation. Specific situation specific analysis, and then to solve.

There are two ways to roll a conical barrel with common plate rolling machines.

– The most convenient is to install a cone rolling device on the machine.

ShenChong 3-roll or 4-Roll plate bending machines are all equipped with cone rolling device for customers to choose. If you have any requirements, please make a request to the roll machine manufacturer.

– Make the rollers into a cone shape with a certain slope.

It produces a large lateral force during rolling. In addition, we should also install lateral reduction gear. The block wheel needs to be quenched.

It will be more complicated to roll a conical workpiece.

We suggest that users purchase a CNC plate rolling machine so that the operation will be more simple and convenient.

With the continuous development of technology, the future work of the bending roller will occur other different faults. At the same time, there will be more and better solutions.

In continuous practice, we will continuously improve the manufacturing and maintenance technology of the plate rolling machine.

The above is about the rolling machine related knowledge points, hope to help your work! As a professional plate rolling machine manufacturer, we sincerely look forward to cooperating with you!