The metal sheet bending process is a common metalworking process widely used in the manufacturing industry. Mechanical equipment and tools are used to apply force to sheet metal, causing it to undergo plastic deformation on a specific die, thereby obtaining metal parts of the desired shape and angle. Bending can not only increase the structural strength of metal sheets, but also form complex geometric shapes to meet the needs of various industrial and commercial applications.

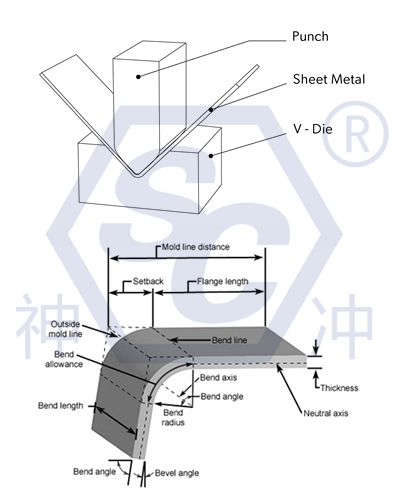

The basic principle of metal sheet bending is to use external force to make the metal sheet plastically deform under the action of the bending die, so as to form a specific bending angle and shape. During the bending process, part of the metal sheet material is stretched and the other part is compressed, finally forming a bending angle.

This process includes several steps:

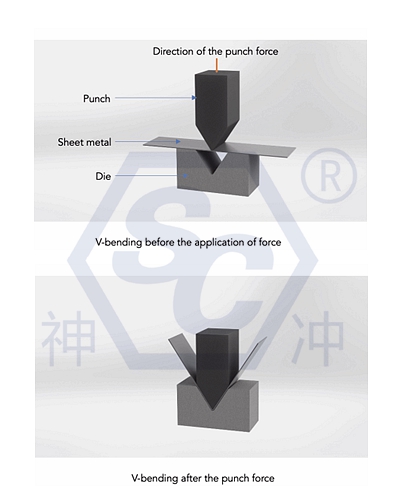

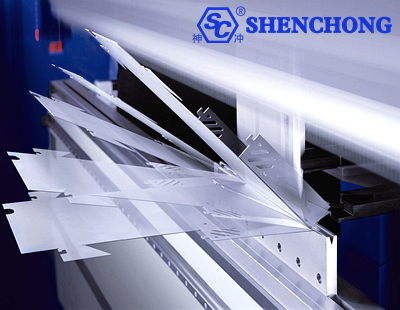

In the bending process, the metal sheet needs to be clamped on the bending die first. The bending die usually consists of an upper die and a lower die. The upper die is usually wedge-shaped, and the lower die is a V-shaped groove or other specific shape of groove. The metal sheet is fixed between the dies by applying force through a bending machine or other mechanical equipment.

Under the action of force, the metal sheet begins to deform plastically.

Stretching and compression: During the bending process, the outer part of the metal sheet is stretched, while the inner part is compressed. The middle part (neutral layer) remains unchanged in length.

Bend formation: As the external force increases, the metal sheet gradually bends to form the required bending angle.

Related article for reference:

What Factors Cause Workpiece Deformation?

After the external force is removed, the metal sheet will rebound to a certain extent due to its own elastic properties. This means that the angle after bending will be slightly larger than when the force was applied. The amount of springback depends on the elastic modulus and thickness of the metal material and needs to be estimated and compensated during the bending process.

In the metal sheet bending process, there are several key parameters and factors to consider:

This is the radius of curvature of the inner side of the metal sheet during the bending process. The smaller the bending radius, the greater the bending force required.

The angle after bending needs to be precisely controlled according to the design requirements.

The force applied to the metal sheet depends on the hardness, thickness and bending angle of the material.

Sheet metal bending force refers to the force applied to the metal sheet during the sheet metal bending process to cause it to plastically deform and form the required bending angle. The magnitude of the bending force depends on many factors, including material type, sheet thickness, bending angle, die shape, and bending method.

P=(K·L·T²)/V

The following empirical formula is usually used to calculate the bending force:

P: bending force, in Newtons (N) or kilonewtons (kN).

K: material coefficient (generally between 1.3 and 1.5 depending on the material type).

L: bending length, that is, the length of the bending line, in millimeters (mm).

T: sheet thickness, in millimeters (mm).

V: lower die width (width of the V-groove), in millimeters (mm).

Click here to know more about:

How to calculate bending force?

Material type: Different materials have different yield strengths, so the required bending force is also different. For example, the bending force of steel is usually greater than that of aluminum.

Sheet thickness: The thicker the sheet, the greater the bending force required.

Bending length: The longer the bending line, the greater the bending force required.

Width of lower die opening: The narrower the width of the lower die opening, the greater the bending force. The wider the width, the smaller the bending force.

In actual operation, the sheet metal bending machine usually displays the value of the bending force and automatically calculates the required force based on the input material and thickness. Accurate bending force calculation is essential to prevent material cracking, ensure bending accuracy, and extend the life of the machine and mold.

The elastic recovery angle of the metal sheet after bending, which needs to be properly compensated.

Related article for reference:

Relationship: Press Brake Radius, Thickness and V Die

Bending Springback of Sheet Metal Parts [Causes & Measures]

Precision Sheet Metal Bending Analysis

Sheet metal bending is a common metalworking process used to bend metal sheets into the desired shape. The process includes multiple steps, depending on the complexity and requirements of the desired product. Here is an overview of the sheet metal bending process:

Select the appropriate metal sheet, such as steel, aluminum or copper, based on strength, flexibility and application requirements.

Determine the thickness of the metal sheet, thicker sheets require greater bending force.

Design the required bending angle and shape using CAD (computer-aided design) software.

Calculate the bend compensation, which is the length of material used for bending to compensate for the stretching and compression of the material during the bending process.

Select the appropriate bending tool (die and punch) based on the material and the required bending radius.

Commission the bending machine, such as a press brake or CNC (computer numerical control) bending machine. Adjust the equipment according to the material thickness and bending requirements.

The metal sheet is placed on the machine and aligned with the bending tool.

The machine presses the sheet into the die through the punch to form the desired bending shape. This process can be manual or controlled by a CNC system for increased precision.

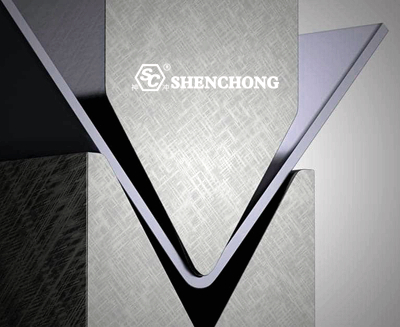

- Air bending: The punch presses the sheet into the die but does not fully contact the bottom of the die, allowing for slight variations in the bending angle.

- Bottom bending: The punch presses the sheet fully into the bottom of the die to ensure a precise bend.

- Imprint bending: The punch applies enough pressure to make the sheet flow and form a high-precision bend.

Use measuring tools to check the bending angle to ensure it meets the design requirements.

Measure the dimensions of the finished product to ensure it meets the required tolerance range.

Remove sharp edges or burrs generated during the bending process.

Surface treatment such as painting, electroplating or polishing is performed as required to enhance the appearance and durability of the product.

Depending on the specific application, the bent metal sheet may need to be assembled with other components or undergo further processing such as welding, cutting or drilling.

Sheet metal bending is widely used in industries such as automotive, aerospace, construction and home appliance manufacturing. Precision and durability are the basic requirements of these industries for bending processes.

The bending of metal sheets requires a variety of equipment and tools to ensure the accuracy and efficiency of the processing process. The commonly used equipment for bending mainly includes bending machines, bending molds and auxiliary tools.

According to different application requirements and processing accuracy, the bending equipment and tools are also different. The following are the equipment and tools commonly used in bending:

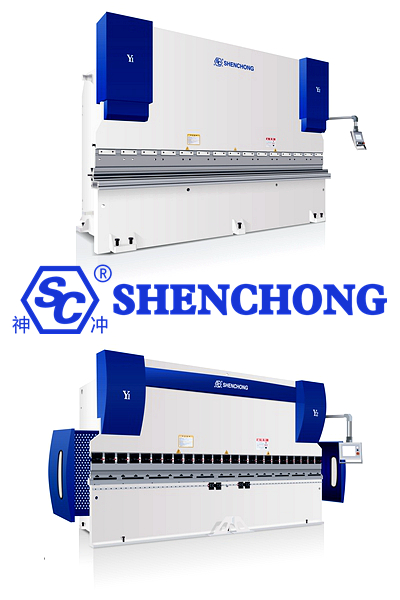

The press brake machine is the main equipment for bending metal sheets. According to the different driving methods and control methods, the press brake machine can be divided into the following types:

- Features: The upper die is driven by a mechanical transmission system for bending.

- Advantages: Simple structure, easy operation, suitable for bending of small and medium-sized plates.

- Application: Mostly used in small batch production and small and medium-sized enterprises.

- Features: The hydraulic system is used to drive the upper die for bending, with strong pressure and stability.

- Advantages: Suitable for bending thick plates and high-strength materials, stable operation and large bending force.

- Application: Widely used in automobile manufacturing, shipbuilding, heavy industry and other fields.

- Features: It is controlled by computer numerical control system and has a high degree of automation.

- Advantages: High precision, high efficiency, easy operation, suitable for bending processing of complex and high-precision parts.

- Application: It is widely used in aerospace, electronics, high-end manufacturing and other fields.

Related article for reference:

Comparison:Electro-Hydraulic, Single Servo, Servo hybrid Press Brake

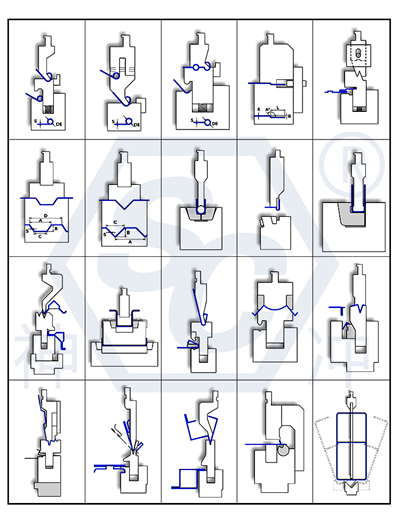

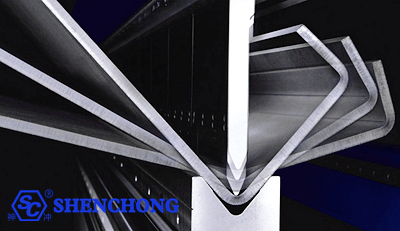

The bending die is the part that directly contacts the metal sheet during the bending process, and is mainly divided into an upper die and a lower die.

- Shape: Usually wedge-shaped, the specific shape is designed according to the bending requirements.

- Material: Mostly made of high-hardness, high-wear-resistant materials, such as alloy steel.

- Shape: Usually V-shaped groove, there are also other specific shapes of grooves, designed according to the bending angle and shape requirements.

- Material: Similar to the upper die material, it must have high hardness and high wear resistance.

Related article for reference:

Press Brake Punch and Die Common Sense

How to Choose Press Brake Tooling and V Die?

Some auxiliary tools are also required in the bending process to ensure processing accuracy and efficiency:

Bending Follower Device For Sale

- Purpose: Used to measure and calibrate the bending angle to ensure the accuracy of the bending angle.

- Type: digital protractor, mechanical protractor, etc.

- Purpose: Used to measure the size of the metal sheet and the length after bending to ensure the accuracy of the size.

- Type: steel ruler, tape measure, etc.

- Purpose: Used to fix and position the metal sheet to ensure the accuracy of the bending position.

- Type: fixture, locating pin, etc.

- Purpose: used to reduce the friction between the metal sheet and the mold during the bending process, and protect the mold and the surface of the metal sheet.

- Type: industrial lubricant, grease, etc.

With the development of science and technology, bending equipment and tools are also constantly upgraded. The following are some modern equipment and technologies:

- Features: The upper die is driven by a dual servo pump control system for bending.

- Advantages: Low energy consumption, high precision, low noise, suitable for production environments with high environmental protection requirements.

- Features: Combine bending processing with automated production lines to achieve continuous and automated production.

- Advantages: High production efficiency, suitable for mass production, and reduce labor costs.

- Features: Use artificial intelligence and big data technology to monitor and adjust bending processing in real time.

- Advantages: Improve processing accuracy and efficiency, reduce scrap rate and production costs.

The bending process parameters of metal sheets refer to the key parameters that need to be controlled and adjusted during the bending process. These parameters directly affect the bending quality, processing accuracy and production efficiency. The metal sheet bending process parameters include bending radius, bending angle, bending force and springback. The main process parameters include the following aspects:

- Definition: The bending radius refers to the radius of curvature of the inner side of the metal sheet during the bending process.

- Impact: The smaller the bending radius, the greater the degree of deformation and the greater the required bending force. Too small a bending radius may cause cracking or damage to the material.

- Selection: Select a suitable bending radius based on the thickness and performance of the material. Generally, the bending radius should be at least 1-2 times the thickness of the material.

- Definition: The bending angle refers to the angle formed by the metal sheet after bending.

- Impact: The bending angle needs to be precisely controlled according to the design drawings and actual needs. Inaccurate angles will affect the assembly and performance of parts.

- Control: Ensure the accuracy of the bending angle through precise mold design and the control system of the bending equipment.

- Definition: Bending force refers to the force applied to the metal sheet during the bending process.

- Impact: The magnitude of the bending force depends on the hardness, thickness, bending radius and bending angle of the metal material. Insufficient bending force will lead to incomplete bending, and excessive force will cause material damage or mold damage.

- Calculation: Use the bending force calculation formula to determine the required bending force.

- Definition: Springback refers to the angle change of the metal sheet under the action of elastic recovery after bending.

- Impact: The springback will affect the final accuracy of the bending angle, and it needs to be compensated and adjusted during the bending process.

- Compensation: Compensate for the springback by adjusting the bending angle, increasing the over-bending angle or using multiple bending methods to ensure the accuracy of the final angle.

- Definition: The bending line length refers to the length along the bending line direction.

- Impact: The length of the bending line determines the distribution and deformation of the material during the bending process, and has an important impact on the final bending effect.

- Calculation: According to the design size and bending angle of the part, calculate the length of the bending line to ensure processing accuracy.

Related article for reference:

Press Brake Bending Unfolded Length Calculation [Y and K factors ]

- Definition: Material properties include the tensile strength, yield strength, ductility and thickness of the material.

- Impact: The characteristics of different materials determine their deformation behavior and bending force requirements during the bending process.

- Selection: Select appropriate materials and corresponding process parameters according to specific application requirements and processing requirements.

- Definition: Mold parameters include the shape, size and angle of the upper and lower molds.

- Impact: Mold design and manufacturing quality directly affect the bending effect and part accuracy.

- Design: According to the bending process requirements, design appropriate mold parameters to ensure the smooth progress of the bending process.

- Definition: Bending sequence refers to the processing sequence during multiple bending processes.

- Impact: A reasonable bending sequence can avoid material interference and processing difficulty, and ensure processing efficiency and quality.

- Planning: According to the geometry and processing requirements of the parts, plan a reasonable bending sequence to improve processing efficiency and quality.

Bending process parameters are the key factors to ensure processing quality and efficiency. By reasonably selecting and controlling these parameters, the accuracy and quality of bending processing can be effectively improved to meet various industrial application requirements.

Bending processing is an important and widely used metal processing process. By understanding its basic principles and process parameters, the metal sheet bending quality can be better controlled to meet various industrial application requirements. In actual production, it is necessary to combine specific materials, equipment and processing requirements, comprehensively consider and adjust these process parameters to achieve the best processing effect.

Bending processing is widely used in the manufacturing industry, especially in the field of metal processing. Here are some of the main application areas:

In automobile manufacturing, metal sheet bending processing is used to manufacture body structural parts, chassis parts, brackets and reinforcements, etc. Bending processing can ensure the high strength and precision of these parts, thereby improving the overall performance and safety of the vehicle.

Bending processing is also important in the aerospace field, and is used to manufacture aircraft and spacecraft structural parts such as wings, doors, brackets, etc. These parts require light weight and high strength, and bending processing can meet these requirements.

In the construction industry, bending processing is used to manufacture building structural parts, steel structures, stairs, railings, guardrails, etc. Bending processing can help realize various complex architectural designs while ensuring the safety and durability of the structure.

Bending processing is widely used in furniture manufacturing, especially in the production of metal furniture. Through bending, various furniture parts with unique designs and beautiful shapes can be manufactured, such as table legs, chair frames and frames, etc.

In the manufacturing of home appliances, the outer casings and internal structural parts of products such as washing machines, refrigerators, microwave ovens, etc. need to be bent. Bending can improve the strength and aesthetics of these parts, while adapting to various complex design requirements.

Some components in medical devices, such as surgical instruments, bed supports, wheelchairs, etc., usually need to be manufactured through bending processing. Bending can ensure the accuracy and reliability of these parts.

In shipbuilding, bending processing is used to manufacture hull structural parts, supports, reinforcements, etc. These parts need to have high strength and corrosion resistance, and bending can help achieve these requirements.

From the above applications, it can be seen that bending plays a vital role in many industries and can help manufacture a variety of complex and precise metal parts.

Related article for reference:

What are the applications of press brake?

Bending processing has many advantages, but it also faces some challenges.

Features: The bending processing speed is fast and suitable for mass production.

Advantages: Improve production efficiency, shorten production cycle, and meet the needs of industrial large-scale production.

Features: Bending processing can handle metal sheets of various shapes and sizes.

Advantages: It has strong flexibility and can adapt to a variety of design and application requirements.

Features: The application of modern bending equipment and CNC technology makes the bending processing precision high.

Advantages: Ensure the accuracy of part size and shape and improve product quality.

Features: Less material loss during the bending process.

Advantages: Improve material utilization and reduce production costs.

Features: Bending processing can increase the structural strength of metal sheets.

Advantages: Make parts more durable and suitable for various applications with high strength requirements.

Features: Complex geometric shapes can be produced through bending, reducing the need for welding.

Advantages: Improve production efficiency while reducing deformation and stress concentration problems that may be caused by welding.

Features: The springback phenomenon in the bending process will affect the accuracy of the bending angle.

Challenge: Compensation and adjustment are required to ensure that the final bending angle meets the design requirements.

Features: The performance of different metal materials varies greatly.

Challenge: It is necessary to select appropriate process parameters based on the hardness and thickness of the material to avoid cracking or deformation of the material.

Features: High-precision and automated bending equipment requires a large investment.

Challenge: For small and medium-sized enterprises, the initial equipment investment cost is high, which may affect capital flow.

Features: Bending requires operators to have a high level of technical skills and experience.

Challenge: Training and maintaining highly skilled operators requires time and cost, affecting the continued stability of production.

Features: Mold design and manufacturing directly affect the effect of bending.

Challenge: High-precision mold design and manufacturing capabilities are required, and mold costs are high, especially for complex shapes and small batch production.

Features: Bending of some complex geometries is difficult.

Challenge: Advanced equipment and technology, as well as detailed process planning, are required to ensure processing accuracy and quality.

Features: The surface of the metal sheet may be scratched or damaged during the bending process.

Challenge: Additional surface treatment and protection measures are required to ensure the surface quality of the final product.

Related article:

Common Surface Treatment Processes for Sheet Metal Materials

Features: Different workpieces require different bending processes and quality control methods.

Challenge: Continuous optimization of process parameters and quality control methods is required to improve processing efficiency and product quality.

As an important metal processing technology, sheet metal bending has the advantages of efficient production, strong flexibility, high precision, high material utilization and enhanced structural strength. However, it also faces challenges such as springback problems, material limitations, equipment investment, technical requirements, mold design and manufacturing, processing of complex geometric shapes, surface treatment and protection, process optimization and quality control. Through continuous technological innovation and process improvement, these challenges can be overcome, the advantages of bending can be fully utilized, and various needs in the industrial and commercial fields can be met.

Bending equipment and tools are the key to ensuring the quality and efficiency of metal sheet bending. With the advancement of science and technology, bending equipment and tools are developing towards high precision, automation and intelligence, which not only improves production efficiency, but also meets diversified and high-precision processing needs.

Metal sheet bending processing plays an important role in modern manufacturing. With the advancement of technology and the continuous changes in industrial needs, its development trend presents the following main directions:

Features: Intelligent bending equipment with integrated sensors, automatic control systems and data processing technology can monitor and adjust processing parameters in real time to ensure high-precision and high-quality bending processing.

Advantages: Reduce human errors, improve production efficiency, and adapt to production needs of different batches and complexities.

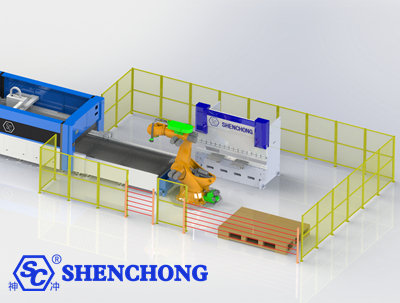

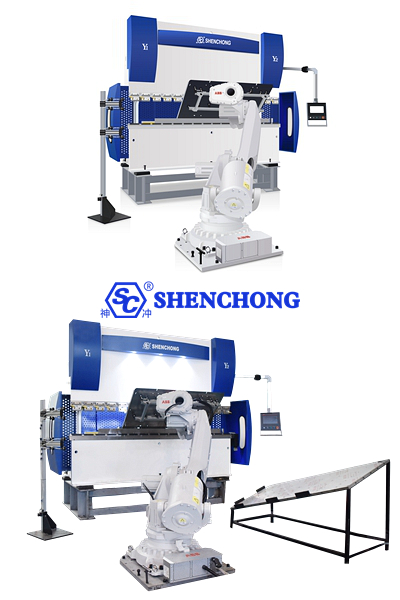

Bending automation refers to the automation and intelligence of bending operations through automated equipment and technology during the bending process. Bending automation systems usually include CNC press brake machines, automated feeding systems, robotic arms, sensors, control software, etc. These systems can reduce manual intervention, improve production efficiency, ensure consistency in product quality, and reduce production costs. The following are the main features and advantages of bending automation:

Automated bending machine is the core equipment of bending automation and is usually controlled by a CNC system. The operator only needs to input the bending program of the workpiece, and the bending machine can automatically perform multiple bending steps, accurately control the bending angle and position, and ensure the consistency of each product.

The automated feeding system can automatically feed the plate or workpiece into the bending machine for processing. It can be linked with the CNC bending machine to ensure accurate positioning and smooth feeding of the material, thereby reducing manual operation time and errors.

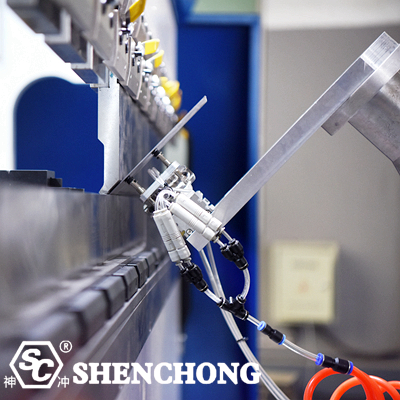

In the bending automation system, the robotic arm can be used to grab, carry and place the workpiece, further reducing manual intervention. These robotic arms can operate flexibly and can handle workpieces of various shapes and sizes.

Sensors are used to monitor key parameters in the bending process, such as bending angle, material thickness, position accuracy, etc. If an abnormality occurs, the system can automatically adjust or stop the operation to ensure the accuracy and safety of the processing.

Bending automation systems are usually equipped with advanced control software that can manage the entire bending process. Through programming and optimization, complex bending processes can be achieved, setting time can be reduced, and production flexibility can be improved.

Bending automation systems can integrate data acquisition and analysis functions to monitor key indicators in the production process in real time. This data can be used in areas such as quality control, preventive maintenance, and production optimization, thereby improving overall production efficiency.

- Improve production efficiency: Bending automation can significantly increase production speed because the machine can work continuously and is not limited by the speed of manual operation.

- Ensure product consistency and quality: Automated equipment can accurately control various parameters in the bending process to ensure that the size and quality of each product meet the standards.

- Reduce labor costs: The bending automation system can reduce the reliance on manual operation, thereby reducing labor costs and reducing the workload of operators.

- Flexibility and repeatability: The automation system can quickly adapt to different production needs, repeatedly produce the same high-quality products, and quickly adjust production plans when necessary.

- Safety: The automation system reduces the intervention of manual operation, reduces the risk of operators in high-intensity and high-risk processes, and improves production safety.

In general, robotic press brake plays an increasingly important role in modern manufacturing, helping companies improve production efficiency, reduce costs, and maintain advantages in fierce market competition.

Features: Combine bending processing with automated production lines to achieve continuous and unmanned production.

Advantages: Greatly improve production efficiency, reduce labor costs, and be suitable for large-scale production.

Related article for reference:

What is a Robotic Work Cell in Sheet Metal Processing?

Robotic Manipulator Ultimate Guide

Features: Use computer numerical control technology to automatically program and control the bending process.

Advantages: High precision, high efficiency, and adapt to complex shapes and small batch production of multiple varieties.

Features: Use digital design and simulation technology to optimize the bending process and discover and solve potential problems in advance.

Advantages: shorten the development cycle and improve product quality and reliability.

Features: Lightweight materials such as aluminum alloys, high-strength steel and titanium alloys are increasingly used in aerospace, automobile manufacturing and other fields.

Advantages: Reduce product weight, improve performance and energy efficiency, and adapt to the modern industry's demand for lightweight and high strength.

Features: The application of new alloy materials such as magnesium alloys and composite materials in bending processing is gradually increasing.

Advantages: Excellent mechanical properties and corrosion resistance to meet special application requirements.

Features: Develop and use high-efficiency and energy-saving bending equipment to reduce energy consumption and carbon emissions. For example, SC hybrid CNC bending machine.

Advantages: Reduce production costs and comply with environmental regulations and social responsibility requirements.

Features: Use environmentally friendly lubricants and clean processes to reduce pollution to the environment.

Advantages: Protect the environment and enhance the social image of the enterprise.

Features: It has the ability to quickly switch and adjust production lines to meet the needs of multi-variety small-batch production.

Advantages: Improve production flexibility and response speed to meet the diversified needs of the market.

Features: Through advanced manufacturing technology and management systems, customized production of personalized products is realized.

Advantages: Improve customer satisfaction and expand market share.

Features: Introduce collaborative robots in bending processing and combine them with manual operation.

Advantages: Improve production efficiency, reduce labor intensity, and improve production safety.

Features: Use advanced safety protection devices and systems to ensure the safety of operators.

Advantages: Reduce safety accidents and improve the safety of the production environment.

In the future, metal sheet bending processing technology will continue to develop in the direction of intelligence, automation, digitalization, high-performance material application, green manufacturing, flexible manufacturing and customized production, human-machine collaboration and safety, as well as innovative processes and technologies.

These trends not only improve the efficiency and quality of bending processing, but also meet the needs of modern manufacturing for diversification, personalization and environmental protection. Through continuous technological innovation and process improvement, bending processing will continue to play an important role in the manufacturing industry and promote industrial progress and economic development.

As an important metalworking technology, metal sheet bending process plays an important role in modern manufacturing. Through continuous technological innovation and process improvement, bending will continue to meet various needs in the industrial and commercial fields and contribute to economic development and scientific and technological progress.

In the future development, bending will continue to move towards intelligence, automation, high-performance materials, green manufacturing and customized production, and promote the development of manufacturing to a higher level.