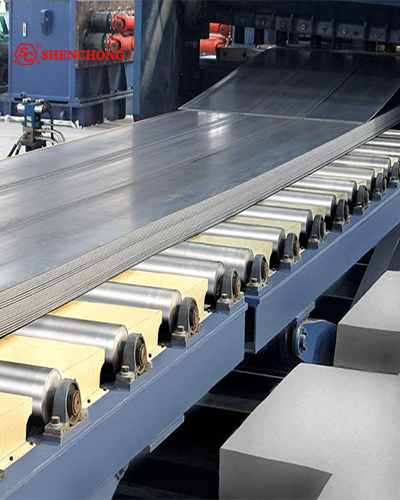

Cut to length and slitting machine lines are equipment that cut raw materials vertically and horizontally according to the actual needs of customers in order to prepare sheet metal plates for subsequent forming processes. Among them, the material after slitting is generally used for continuous production, such as: automatic pressing, rolling, secondary slitting and shearing, etc. The material after cut to length is generally used for single forming processing. Such as: bending by using hydraulic press brake, pressing by cnc press machine, stretching and so on.

Since the slitting line generally retains the function of rewinding all the sheet metal raw materials after slitting, the simplification of the slitting line is relatively simple compared with the cut to length line. Generally, the plate width is less than 800mm, the thickness is more than 0.5mm and less than 2mm, the strength of the plate is less than 300MPa, the bearing capacity is less than 5 tons, and the production speed is about 40m/min. The simplification method generally adopted is to replace auxiliary equipment such as hydraulic or pneumatic with manpower. And because the roll of this kind of material is lighter, the production speed is slower, and the rigidity of the frame is easy to ensure. And the installed capacity is low, the floor area is small, and it is suitable for small batch production. However, with the increase of the board width, the thickness of the material is thickened, the material coil is heavier, and the production speed is increased. All kinds of safety factors need to be greatly improved in the design, and the purpose of simplifying the design cannot be achieved.

Compared with the single simplified design of slitting machine line, the simplification of cut to length line is obviously diversified. Not only is the matching feeding system changeable, but also the shearing board and the stacking system behind it are also different according to different needs, and there are many combinations of each other. Change. The form cannot be unified at all, so understanding the internal parallel connection of the related equipment combinations is one of the keys to quickly grasp the configuration of the simple cross-cutting line.

In fact, we can look at the entire cut to length line as an alternative ordinary pressing line. The essential difference between these two types of machine is that there are many sheet metal plates in the pressing line that do not need to be corrected, while that in the cut to length line needs to be corrected without exception. Even in many high-end production, the configuration of the straightening machine directly determines the quality of the cut to length line. Based on this, we can regard the shearing mechanism itself as a punch machine, and if the shearing blades are regarded as a mold, the entire cut to length line can be disassembled into a concept similar to conventional punching lines such as peripheral equipment, punch and mold, product collection, etc. Now let us analyze the basic configuration conditions of each equipment in the simple cut to length line.

Click here to know:

Steel Coil Cut To Length Line Advantages

The material bearing and correction part of the simple cut to length line are also selected according to the customer's material. Like conventional stamping lines, it can be combined according to separate equipment, two-in-one (GO, ML, CL, TGL, etc.). The material bearing part selects the model according to the material width and inner and outer diameter, the pressing method according to the material thickness, and the power size and expansion method according to the load bearing, and whether to configure auxiliary support. The straightening part selects the size and arrangement of the straightening wheel according to the material thickness, confirms the power of the straightening machine according to the speed, and determines the number, arrangement and transmission mode of the straightening wheel according to the customer's requirements for flatness. As an export equipment, it is recommended to take into account that many countries generally pay more attention to safety, and it is recommended that the pressing arm of the material rack and the corrected frequency conversion speed regulation in the quotation should be considered as standard equipment.

The feeding part of the simple cut to length is completely differentiated and selected according to the customer's requirements for the size and efficiency of the plate. According to the difference of power source, it is divided into: AC frequency conversion fixed length, DC motor fixed length and servo motor fixed length. For building cross shears with poor material quality and large fixed-length tolerance requirements, the circuit consisting of a rectifying power plus inverter and a length-measuring encoder can be directly used to determine the length. For materials with large thickness and strength, but low production capacity requirements, a loop composed of a DC motor and a length-measuring encoder can be used for sizing. For those with high speed requirements, production capacity requirements and high automation requirements, servo sizing is selected.

The shearing part of the simple cut to length is specifically divided into: the plate head shear that comes with the equipment, the outsourced finished hydraulic shearing machine, and the pneumatic clutch high speed shear (or hydraulic high speed shearing machine), etc. For simple cut to length lines with small output requirements, the plate head shears can be directly cut. For some relatively medium and low-grade cross-cutting lines with wide material width and large thickness range, outsourced hydraulic shearing machine can be used. For high shearing requirements and certain speed requirements, choose pneumatic clutch high speed shears or hydraulic high speed shears.

The collection method of the simple cross-cutting line depends entirely on the nature of the production line required by the customer. It can be divided into manual collection, simple lifting collection and automatic stacking collection. For self-use equipment with thin material, short cutting length and low output, manual collection and stacking can be used. For fixed cross-cutting lines with long cutting lengths (generally longer than 600mm, beyond the manual clamping range) with little change in material width, lift forklifts can be used for fixed-length collection. For mass production with large variation in material width and material length or the nature of the customer itself as a material supplier, automatic stack collection is the first choice.

The simplified design of the slitting and cut to length lines used in the initial production of materials is developed and designed on the basis of maintaining the basic functions of the corresponding production lines. Especially for cut to length lines, different matches can be produced according to different combinations to meet the needs of different types of production. Like the stamping production line, it needs to make the best configuration plan according to the final needs of the customer. Therefore, a real understanding of the customer's real purchasing purpose is the beginning of all work.

After using the cut to length lines, sheet metal plates also need to bend by using cnc press brake machine. Wuxi Shenchong Foring Machine Co.,Ltd is a professional CNC press brake manufacturer with more than 20 years experience. Shenchong has all kinds of hydraulic press brake for sale. Welcome to contact with us and send your press brake machine inquiry today!