The safety protection device of the press brake, that is, the laser is an electro-sensitive protection and control device, which has the function of protecting the operator in the event of an accident.

Under the following circumstances: before a part of the human body is squeezed by two relatively moving metal parts, this part of the human body will at least cut off at least one beam of light in the grating, thereby sending a signal to interrupt the stroke. In this way, the machine is stopped to prevent the operator from being injured.

Know More About CNC Hydraulic Press Brake

- Used when fixing the same height mold at the same position. All molds used must be pressed down along the same bending line.

- The obstruction installed on the lower mold will cause the slider to stop moving downward prematurely.

- The larger allowable overshoot distance of the machine tool: the 10mmpress brake must have a control that automatically detects the stroke distance in the previous stroke; must pass the test rod before the previous start or Use an over travel measuring tool to measure the allowable stroke distance.

- If the distance of 10 consecutive overshoots exceeds 10 mm, the speed of the machine tool must be reduced.

- Since the two machine tools cannot be synchronized during fast down, the laser protection device cannot be used for two machine tools placed side by side.

- If the beam is interrupted by the bent steel plate, the protection device of the press brake will immediately stop the working stroke. Therefore, the press brake safety device must enter the working state before being blocked by the steel plate. Similarly, some uneven steel plates should not cause unnecessary travel interruptions. From an opening less than 13-22 mm (according to the allowable overshoot distance of the press brake), the machine tool control system must send a soothing signal to the receiver. Then the press brake control system must be able to reliably ensure that the bending speed is less than 10 mm/s thereafter.

- The press brake laserprotection device of the press brake cannot guarantee the bending of the bottom of the box in the box folding mode.

- The laserprotection device of the press brake cannot protect: if the machine tool is only running at the working speed, or the safety protection device may be terminated under high-speed operation, and the stroke may be continued at the working speed.

- If the overshoot distance moved when the press brake is braking is too long. Extrusion during the bending process. When the soothing light is on continuously.

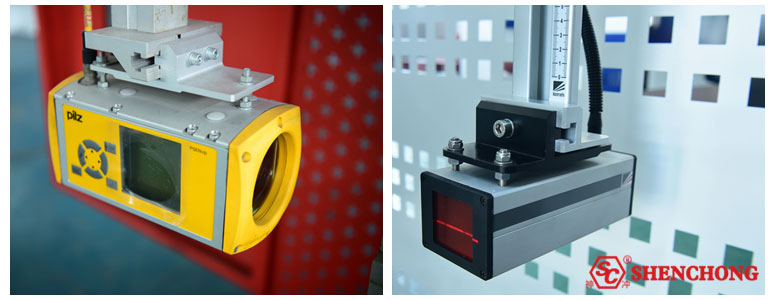

– The design of the mounting bracket (to install the transmitter and receiver on the mounting arm)

Different sizes of press brakes must be designed with matching mounting arms. The mounting arm must be installed on a hard rigid material, such as a round steel tube 80*50*5 mm.

The mounting arm must be as long as possible so that both large and small molds can be installed normally. If the mold is changed frequently, the receiver must be mounted on a rotatable mounting arm, so that the transmitter arm does not need to be adjusted.

– Installation of the mounting arm

The mounting arm must be installed to ensure that the sending end and the receiving end are directly facing the bending line of the machine tool.

The distance between the mounting arm and the body of the press brake should be greater than 100mm to prevent damage to the machine body during the working process of the press brake.

The identifier on the machine tool must be installed to remind the operator not to be too close to the machine tool to affect the operation of the safety device. In the same way, any dangerous items should not be too close to the laser safety device.

Attention!

The sending and receiving devices on the safety device of the press brake cannot be squeezed (for example, the bottle cannot be placed on it). In order to prevent the device from being damaged, a solid protective cover must be used to protect it. Ensure that no other objects are placed under the press brake laser protection device and the mounting arm to avoid damage caused by collision during the bending process.