With the increase of labor cost, the sheet metal industry has higher and higher requirements for efficiency and energy saving of press brake bending.

Due to the progress of technology, all-electric press brake has entered the market. Also, the hydraulic press brake has been upgraded. And, the hydraulic-electric servo hybrid press brake is becoming more and more popular.

Which CNC press brake is suitable for your workshop or metal processing business? Read on and you'll find the answer.

Hydraulic press brake has always been the mainstream equipment in sheet metal bending industry, in an unshakable position.

Hydraulic bending technology is also constantly improving and developing. Moreover, the hydraulic press brake manufacturers also provide energy-saving, environmental protection, efficient options.

Hydraulic press brake machine adopts hydraulic transmission mode. The oil cylinders at both ends of the machine tool placed on the sliding block drive the operation directly.

Your understanding of the hydraulic bending machine can’t be limited to the most common torsion shaft press brake. Now, there are many high-end hydraulic press brakes for sale on the market, which are worth purchasing.

The original version of hydraulic bending machine is NC/CNC torsion shaft type.

Later, the manufacturer introduced the electro-hydraulic synchronous press brake.

In recent years, in order to achieve energy-saving and high efficiency, manufacturers have launched electro-hydraulic servo press brake (single servo pump control) and hybrid servo press brake (double servo pump control) to meet the needs of different users.

– Mature and advanced technology

After decades of experience and test, the mainstream hydraulic technology is certainly much more mature than the emerging electronic technology.

And the hydraulic bending technology is favored by most people, and has never been eliminated for so many years. Facts have proved that it’s very stable and reliable.

In addition to a ordinary hydraulic technology, we have also explored the electro-hydraulic technology and hybrid servo technology and so on.

– Wide range of applications

There are many kinds of hydraulic bending machine. We can design the tonnage and the worktable of press brake according to the plate length, width, thickness and workpiece drawing.

You can choose the most suitable model according to the requirements of precision and operation.

Not like the electric bending machine: single type and limited by tonnage, narrow selection surface. CNC hydraulic press brake machine is very suitable for processing large tonnage and large volume parts workshop.

– Rich and diverse types

From low-end to high-end, small to large-scale, NC/CNC to robotic, there are various categories of hydraulic bending machine to choose from. Comparatively speaking, the choice of electric press brake is very simple.

For users with limited funds and low requirements, they can choose the hydraulic torsion shaft press brake with low price but stable operation.

It is one of the best-selling products. The audience is very wide. It has reasonable price, high precision and convenient operation.

There are also special electro-hydraulic bending machines:

- Single cylinder mini hydraulic press brake for small work pieces.

- Heavy duty tandem hydraulic press brake for large plates.

If you want to experience the pump control technology and don’t want to buy too expensive, the single servo energy-saving electro-hydraulic bending machine is your best choice.

Adding servo pump control technology to the common electro-hydraulic brake press can achieve a certain energy-saving effect.

In view of the high standard, high request customer group, we recommend the double servo pump control series hybrid press brake.

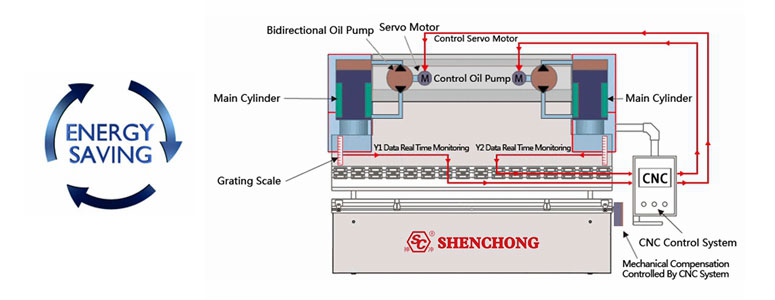

The independent AC-servo motors drive high efficiency bi-directional hydraulic pumps structure that provide extremely fast bending speed and ultra-high precision.

Previously, the hydraulic press brake is not environmental protection and energy saving has been the biggest drawback compared with pure electric press brake.

Hybrid servo model is the upgrading and improvement of hydraulic bending machine after the hydraulic press brake manufacturers study the advantages of electric bending machine.

Energy saving 80%, low noise 20 dB, green environmental protection are its most attractive features for users.

Hybrid types can offer the best of both hydraulic and electronic models.

This type not only has the reliability and practicability of hydraulic press brake, but also has the advantages of environmental protection and energy saving of electrical press brake. In recent years, it is liked by many users.

Reasonable press brake machine price

If you want develop the factory towards automation and flexible production line, the CNC hydraulic press brake with high configuration can install robot for automatic bending.

Automation is a major trend in manufacturing. Robotic press brake bending is also very popular in recent years!

The price of hydraulic press brake is much cheaper than that of all-electric press brake.

The price range of hydraulic bending machine is relatively wide, as low as several thousand dollars, as high as more than 100,000 dollars. Users can choose freely according to their needs and funds.

– Hydraulic system greatly affected by temperature

The change of temperature will cause the instability of hydraulic oil and affect the operation of the whole hydraulic system.

Too high temperature will affect the working speed and bending accuracy. So the hydraulic bending machine needs to be warmed up or shut down for heat dissipation.

– Troublesome maintenance of hydraulic system

The hydraulic oil needs to be changed regularly.

Pumps, valves and seals are easy to malfunction and damage.

The hydraulic system is easy to be polluted.

Technical requirements for troubleshooting are high and time-consuming.

Once the hydraulic system is polluted, cleaning is very troublesome and will cause environmental pollution.

Therefore, the user must buy a good quality hydraulic bending machine, so as to avoid the trouble of maintenance.

– In terms of high speed and energy saving

Although the new generation of hydraulic bending machine servo series has been improved, its speed and efficiency is still not comparable to full electrical press brake.

– Pollution problem

In the use and maintenance of hydraulic press brake machine, it is easy to leak hydraulic oil. This will cause environmental pollution.

For example:

When the hydraulic components are aged or not used properly

Maintenance and replacement of hydraulic components

When changing hydraulic oilPollution is an unavoidable defect of hydraulic system. Please be careful in operation and maintenance!

With the maturity of high power and high torque servo motor and drive technology, and the reduction of cost, the related electronic servo drive devices are applied more and more.

CNC press brake widely used in sheet metal industry opens a new trend of all electric servo drive replacing hydraulic main drive. The tonnage and output of all-electric press brake are increasing.

Press brake machine uses servo-electronic bending technology, we call this electric press brake, E-brake, electrical press brake or electronic press brake.

It adopts full electric drive and full working length back gauge. No harmful hydraulic oil. Noiseless operation and low CO2 emissions.

The most important feature of all electric press brake is that it does not use hydraulic pressure to bend metal, but completely relies on motor driving bending mechanism.

– Energy saving

One of the advantages of pure electronic servo drive technology is that the input power of motor is directly proportional to the load power.

Therefore, bending consumes a lot of power. The power consumption is small when the slider moves up without load. There is no power consumption when the slider stops.

In addition, the mechanical transmission efficiency of pure electronic servo press brake is more than 95%.

– Low maintenance cost

Pure electric bending machine has fewer components and faster maintenance and repair. It does not use hydraulic oil. There is no trouble in changing hydraulic oil and replacing hydraulic components.

The manufacturers carry on the finite element analysis to the machine body and the slide block, optimizes and strengthens the rigidity of the frame and the slide block.

The electric transmission system is simple, there is no maintenance cost, only need regular lubrication.

– Environmental protection and pollution-free

There are no hydraulic oil leakage in the process of replacement, disassembly and daily use of the system. No waste oil treatment and pollution hazard.

– Fast slider speed, high production efficiency

The design and manufacture of all electrical bending machine aims at high bending precision, high efficiency and high reliability.

The electric drive responds faster than the hydraulic drive. So the sliders of the electric bender run faster.

– Adjustable bending speed

You can set more suitable bending speed for different thickness, different material and different length to improve accuracy and ensure high productivity.

– Low conversion rate from electricity to pressure

It takes about twice as much electricity to produce the same pressure as the hydraulic press brake. It has not fundamentally solved the problem of energy saving.

– Tonnage limit

Another drawback is that they can only handle smaller parts and produce up to 80 tons of bending force.

Safan is the most complete manufacturer of electronic bending machines in the world. As the inventor of E-brake, Safan Darley’s servo electronic press brakes can only reach 300 tons at most. Not to mention some ordinary manufacturers.

The Heavy duty press brake with large tonnage can not be a fully electric type. You’ve never seen a 500 ton electronic bending machine. But hydraulic press brake can be as high as thousands of tons.

Therefore, most of the hot selling types on the market are small electric press brakes or boxer electric press brakes.

– The technology is not mature enough

In the past decade, due to the change and development of technology, electric bending machine has made remarkable progress.

However, the electric press brake technology is not as stable and mature as the hydraulic press brake technology.

It is difficult to guarantee the failure rate. Once there is a problem, common engineers or operators can not quickly find the error codes to solve.

– High price

All electric bending technology is very complex, ordinary manufacturers are difficult to produce excellent electric bending machine.

We should select reliable professional electric press brake manufacturers. Such as: Safan, Trumpf, Toyokoki and Prima power. The prices of these brands’ machines are very high.

It depends on the type of parts you want to make and the tonnage required to make them.

– If you specialize in the production of very small parts, small or boxer electrical press brake will be suitable for your business needs.

– If you are dealing with a wider range of parts or require large tonnage, the electro-hydraulic or hybrid servo press brake will be a better choice.