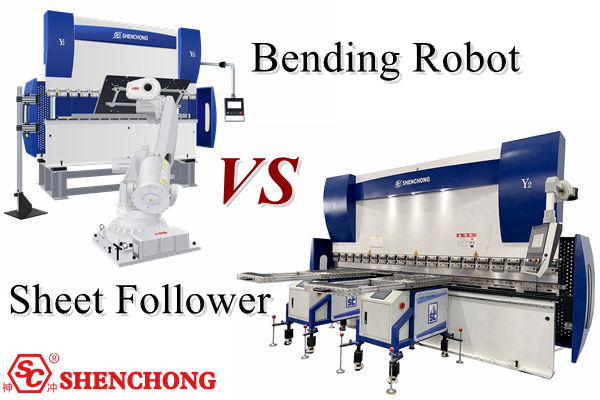

Both bending robot and sheet follower are used to assist CNC press brake machine to achieve semi-automatic or fully automatic sheet metal bending processing.

In the modern metalworking industry, the operation of many bending machines has been upgraded from the original manual operation to a bending robot or bending follower with higher automation and more complicated processing environment.

In the automation of the bending machine, the robotic manipulator and the follow-up supporting device are the two most important auxiliary modes. So, what are they suitable for? What are the advantages and disadvantages? How should users choose?

At present, the mainstream fully automatic bending scheme on the market is completed through the combination of manipulator and bending machine. This combination mode is applicable to most mass production situations with less die replacement frequency. After the mold clamping is completed, the manipulator holder or suction cup absorbs the metal sheet for processing.

Compared with manual, the advantages of bending robots are reflected in three aspects: efficiency, safety and quality. The advantages of efficiency and safety are obvious. There are two main advantages in terms of quality.

First, the positioning of the robot is accurate and repeatable. And good clamping effect to prevent wrinkles. Because the worker has to support the work piece with both hands to follow the action, but the two hands must have precedence.

Uneven stress on the work piece can cause wrinkles. Whereas the robot uses a jig, both sides are machine positioning. It is very accurate, and there will be no errors that humans cannot avoid and measure.

- It can realize flexible combination of multiple CNC machine tools.

- The automatic loading and unloading and workpiece clamping with multiple degrees of freedom meet the requirements of highly difficult production processes.

- Industrial CCD visual inspection can be configured to realize free grasping of complex workpieces.

- Realize continuous mass production of single work piece.

- High adjustability: realize communication with CNC machine tools, PLC, external sensors and other equipment.

- Through programming, realize safe and reliable process control.

- Versatility: high performance anti-collision, product detection, palletizing, warehousing and other optional functions.

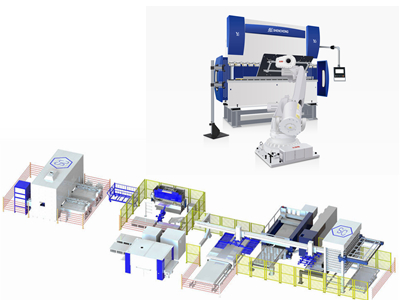

- It can easily realize multi line automatic production line and "digital" factory layout.

- Save manpower to the greatest extent and improve the technical image of factory production.

- Robots are expensive. The production investment cost is high.

- There are also some requirements for the existing bending equipment in the factory, and even necessary modifications to the equipment.

- The design process is more complicated. It requires the user to have a comprehensive and detailed understanding of the production process and the workshop environment.

When the bent sheet is particularly large, you want to save labor. While the mold needs to be replaced frequently, the robot debugging becomes particularly cumbersome. At this time, the bending sheet follower is a good choice!

This method can be used for multiple varieties and large or small batch production, with obvious advantages for large work pieces and thick plates. Reduce bending auxiliary personnel, reduce labor intensity, and have strong flexibility.

By applying the follow-up device, the CNC plate bending machine can quickly complete semi-automatic production.

The Best Price: 5,000 USD

- Save labor.

- Low investment cost.

- Improve the machining efficiency of machine tools.

- The follow-up device and the sheet bending action are fully synchronized.

- Suitable for matching with various brands of different models of press brakes.

- Independent control system: no need to retrofit existing machines.

- There is no need to obtain any signal from the electrical box, avoiding unnecessary disputes with customers.

- It can be moved at any time to match different bending machines.

- Not completely automated.

- It still needs a small amount of manual assistance.

At present, most factories are manual support materials. Ordinary plates only need one person to operate a bending machine. When it comes to large-format sheet metal, it often takes 4 to 6 people to operate a bending machine. It is extremely labor intensive, and the instability of manual palletizing is easy to cause product quality problems. That is also not conducive to production control.

At this time, the user will consider buying a robot manipulator or a follow-up device to assist in bending. Both are very popular automatic bending tools in the market. But their applicable scenarios are slightly different.

For users who produce the same kind of work piece in a single mass production, if the funds are sufficient, we recommend you to choose robot bending with high degree of automation.

Because robots are more durable and more advanced. For large factories, the transformation of intelligent and automated workshops is sooner or later. Then, robotic fully automatic bending is a more prescient option. High productivity and efficiency to shorten order cycle: robots solve the labor intensity and safety risk problems of manual operation.

To sum up, robotic press brake bending solution is suitable for enterprises that process large work pieces, large quantities and few kinds of work pieces. Provide factory layout drawings and work piece drawings, and we will design a set of automatic robot bending solutions for you.

For small and medium-sized factories with limited funds, the sheet follower device is the best choice for you to save labor costs and improve efficiency!

Fast, convenient and cost-effective, are the biggest features of the bending follow-up. Independent mechanical and electronic control, you can experience time-saving and labor-saving bending operation without complex modification!

The bending follow-up trolley and press brakes can quickly form a semi-automatic production unit. It can quickly and flexibly proof samples and mass produce while saving labor, which has good economic benefits.