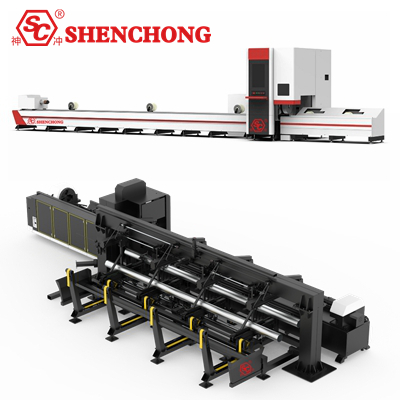

Fiber laser tube cutting machine is a kind of high-efficiency and precision processing equipment specially used for cutting metal tubes or pipes. It uses fiber laser as light source, with high energy conversion efficiency and excellent cutting effect.

Fiber laser pipe cutting machine is a kind of equipment specially used for cutting metal tubes. It uses fiber laser technology for high-precision and high-speed cutting. Fiber laser transmits laser beam through optical fiber, focuses it on the surface of metal tube, and quickly melts or vaporizes the material through high temperature, so as to achieve the purpose of cutting.

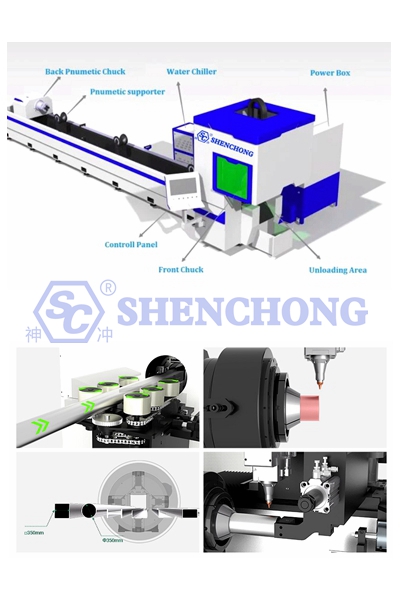

The structure of tube fiber laser cutting machine is relatively complex, and it is composed of multiple important components, each of which plays a key role in a specific link of the cutting process. The following are the main structures and important components of fiber laser pipe cutting machine:

This is the core component of the equipment, responsible for generating high-energy laser beams. Fiber lasers have efficient and stable beam output capabilities.

Fibers doped with rare earth elements (such as erbium and ytterbium) are usually used as gain media, which have the characteristics of high photoelectric conversion efficiency, low energy loss, and long service life.

The laser beam generated by the fiber laser is transmitted to the cutting head through the optical fiber. The fiber transmission system ensures that the laser beam maintains high power and stability during transmission.

The optical fiber is flexible and can easily guide the laser beam to the cutting head to achieve complex path design.

The cutting head is the part where the laser beam directly interacts with the material. It is responsible for focusing the transmitted laser beam onto the surface of the metal pipe and controlling the focal position and cutting path of the laser.

The cutting head is usually equipped with an autofocus function to ensure that the laser beam is always in the best focus state during the cutting process. The cutting head can also adjust the laser emission angle to adapt to pipes of different thicknesses and shapes.

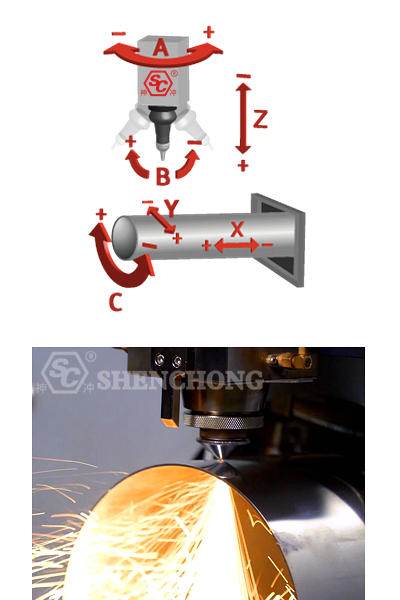

The system is responsible for accurately controlling the movement path and speed of the cutting head to ensure that the laser cutting is carried out according to the predetermined design drawings.

The motion control system is usually based on numerical control (CNC) technology and can perform precise control in three-dimensional space. It includes high-precision transmission components such as servo motors, guide rails, and ball screws.

Used to fix and rotate metal pipes to ensure that the pipes remain stable during the cutting process and can perform 360-degree rotation cutting.

The clamp usually has an automatic adjustment function to adapt to pipes of different diameters and shapes. The rotation mechanism ensures that the cutting head can continuously cut around the pipe.

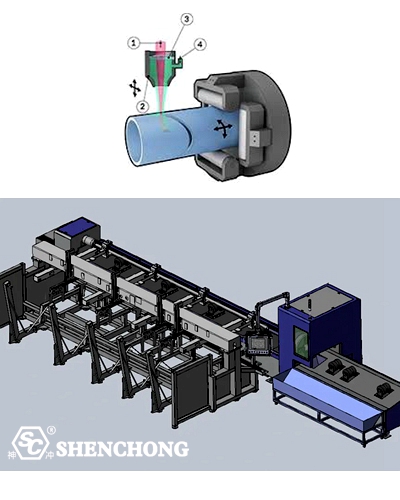

During the cutting process, auxiliary gas (such as oxygen, nitrogen, air) is sprayed to remove molten metal, cool the cutting area, and prevent oxidation during the cutting process.

Different auxiliary gases have different effects on the cutting effect. For example, oxygen can accelerate the cutting speed, while nitrogen helps prevent oxidation and ensure smooth incisions.

The fiber laser tube cutting machine generates a lot of heat during operation. The cooling system is used to cool the laser, optical fiber and other important components to prevent the equipment from overheating.

Usually a water cooling or air cooling system is used to ensure that the equipment maintains a stable temperature while operating efficiently.

Manage and coordinate the workflow of each component, including laser power, cutting path, gas flow, fixture adjustment, etc., to achieve automated operation.

Modern tube pipe fiber laser cutting machines are usually equipped with an integrated operation interface. Users can set cutting parameters by programming or loading CAD drawings to achieve fully automatic processing.

Real-time monitoring of various parameters in the cutting process, such as laser power, temperature, gas pressure, etc., to ensure safe and stable operation of the equipment. At the same time, the safety system can detect abnormal conditions and stop working immediately to prevent accidents

Usually includes camera monitoring, laser protection cover, emergency stop button, etc. to ensure the safety of operators and equipment.

The machine bed is the basic structure of the entire equipment, supporting and stabilizing all components. It needs to have sufficient rigidity and stability to resist the vibration and load generated during the cutting process.

The machine bed is usually made of high-strength steel or cast iron to ensure that it does not deform during high-precision cutting.

During the cutting process, metal materials will produce slag and smoke. The slag removal system is used to collect and remove these wastes to keep the cutting area clean.

Automatic cleaning methods are usually adopted, such as automatic exhaust devices or waste collection tanks, to reduce manual intervention.

The fiber laser tube cutting machine can achieve efficient and precise metal tube cutting through the coordinated work of these important components. Each component plays a key role in a specific link in the cutting process, from laser generation and transmission, to motion control and automated operation, to cooling and safety monitoring, together forming an efficient, stable and precise cutting system.

The working principle of fiber laser pipe cutting machine is based on the high-energy laser beam generated by fiber laser, which is focused on the surface of metal tube through a series of optical components, and the high temperature energy of laser is used to melt or vaporize the material to achieve cutting. The following are the detailed steps of the working principle of fiber laser tube cutting machine:

Fiber laser is excited by optical fiber to generate a high-power laser beam with a wavelength of usually 1064 nanometers. Fiber laser uses optical fiber doped with rare earth elements (such as erbium and ytterbium) as a gain medium, and generates stimulated radiation under the action of pump light, thereby outputting a high-energy laser beam.

The generated laser beam is transmitted through optical fiber and focused by a set of optical lenses or reflectors, so that the laser energy is concentrated on a very small point. The energy density of this focus point is extremely high, which can instantly melt or vaporize the metal material.

When the focused laser beam is irradiated on the surface of the metal tube, the high-energy laser will quickly heat the material to its melting point or vaporization point, forming a small hole. The laser head moves along a predetermined path, and the laser beam cuts along this path. During the cutting process, auxiliary gases (such as oxygen, nitrogen or air) are usually used to blow away the molten metal or vapor to form a clean cut edge.

The laser head of the pipe tube CNC fiber laser cutting machine is usually mounted on a high-precision motion control system, which can perform precise three-dimensional movements according to the numerical control (CNC) program. This enables the laser head to cut along complex paths on the surface of the metal tube, regardless of the shape of the tube (round, square, oval, etc.).

Many fiber laser pipe cutting machines are equipped with automation systems such as autofocus, automatic feeding and automatic discharge. These functions can further improve cutting accuracy and production efficiency and reduce human intervention.

During the cutting process, the laser head cuts the metal tube into the desired shape and size according to the preset path. After the cutting is completed, the cut piece is usually automatically discharged and ready for the next step of processing or assembly.

The pipe fiber laser cutting machine uses the high-energy laser beam generated by the fiber laser to perform high-precision and high-efficiency cutting on the surface of the metal tube. The core principle is to use the high energy density of laser to melt or vaporize the material and achieve precise cutting path through motion control system. This technology is widely used in various metal processing fields, especially in application scenarios that require high-precision cutting.

The fiber laser pipe cutting machine has the following significant features:

Fiber laser pipe cutting machines can achieve extremely high cutting accuracy. The focus point of the laser beam is very small, the energy is concentrated, and it can perform extremely fine cuts, ensuring that the cuts are neat and smooth, without the need for secondary processing. Especially suitable for industries requiring high-precision processing.

The cutting speed of the fiber laser pipe cutting machine is very fast, especially when cutting thin-walled metal pipes. Fiber lasers have high photoelectric conversion efficiency and small energy loss, so they can achieve efficient cutting with lower energy consumption.

This equipment can cut a variety of materials, including stainless steel, carbon steel, aluminum alloy, copper, titanium alloy and other metal pipes. It can handle pipes of different shapes and sizes, such as round pipes, square pipes, oval pipes, special-shaped pipes, etc., and is widely used in automobile manufacturing, construction, furniture, metal processing and other industries.

Fiber laser pipe cutting machines are usually equipped with advanced numerical control systems (CNC), which can automatically adjust the cutting path and process parameters according to the design drawings. This flexibility makes it easy to handle complex cutting needs and is suitable for customized processing.

Modern fiber laser pipe cutting machines usually integrate functions such as automatic feeding, automatic focusing, and automatic discharging. These automated functions not only improve processing efficiency, but also reduce manual intervention and reduce the possibility of human error.

Fiber lasers have a longer life and lower maintenance requirements than other types of lasers, such as CO2 lasers. Since there are no complex optical components inside the fiber laser, it has a compact structure, long service life, and low maintenance costs.

The photoelectric conversion efficiency of fiber lasers is as high as more than 30%, which is much higher than traditional CO2 lasers. Higher energy utilization not only reduces energy consumption, but also reduces equipment operating costs.

The fiber laser tube cutting machine does not require the use of chemical reagents or lubricants during the processing, reducing environmental pollution. At the same time, the heat generated during the laser cutting process is concentrated, which will not have too much impact on the surrounding materials, and also reduces safety risks such as fire.

The fiber laser itself is small in size and light in weight. The design of the entire tube fiber laser pipe cutting machine is relatively compact and occupies a small area. This makes its placement on the factory floor more flexible.

Because fiber laser pipe cutting machines can cut at high speed and usually have automated functions, they can run continuously and uninterrupted, which greatly improves the overall efficiency of the production line and is especially suitable for large-scale production applications.

These characteristics make fiber laser tube cutting machines an indispensable and efficient tool in modern industry, and are widely used in various metal processing fields that require high-precision and high-efficiency cutting.

Laser Tube Cutting Technology Characteristics And Industry Applications

Fiber laser pipe tube cutting machine has been widely used in many industries, especially in scenarios that require high-precision and complex shape cutting. The following are the main application areas of fiber laser tube cutting machine:

- Exhaust system: used to cut metal pipes with complex shapes such as automobile exhaust pipes and mufflers.

- Frame structure: precisely cut metal pipes used in the body structure to ensure the accuracy of welding and assembly.

- Seat frame: metal frame used to produce car seats to ensure the strength and precision of seats.

- Building steel structure: cutting steel pipes, support frames, etc. for construction to ensure the precise size and shape of structural parts.

- Decorative materials: used to make metal pipes in architectural decoration, such as handrails, guardrails, etc.

- Metal furniture frame: cutting the frame parts of various metal furniture, such as chairs, tables, bed frames, etc.

- Decorative components: used to cut decorative metal parts in furniture, providing a variety of designs and shapes.

- Customized Metal Parts: used for small batch production or customized metal pipe products, such as pipe parts and accessories in industrial equipment.

- Component Processing: high-precision cutting of various metal parts, suitable for the manufacture of a variety of machinery and equipment.

- Aircraft Structure: precise cutting of metal pipes used in aircraft structures, such as support frames, seat frames, etc., to meet the requirements of high strength and lightness in the aviation field.

- Pipeline System: used to cut complex pipeline systems in aircraft to ensure the accuracy of airflow, fuel and other pipelines.

Surgical Instruments: cut high-precision stainless steel or titanium alloy pipes for making surgical instruments and medical equipment parts.

Stents and Implants: used to make medical implants that require high precision and complex shapes, such as stents, catheters, etc.

- Household Appliance Internal Structural Parts: used to cut metal pipes and frame parts inside household appliances, such as pipes and brackets in refrigerators and washing machines.

- External Decorative Parts: cut metal parts for the outer shell of household appliances to ensure appearance and functionality.

- Fitness Equipment Frame: used to cut and manufacture metal frame parts of fitness equipment, such as treadmills, exercise bikes, etc.

- Accessories Processing: cut various types of metal pipe accessories used in fitness equipment to ensure the durability and safety of the equipment.

- Pipeline Processing: cut oil and gas pipelines to meet the precision requirements under high pressure environments.

- Drilling Equipment: used to make metal pipes and accessories in drilling equipment to ensure durability and precision.

- Bicycle Frame: cut metal pipes for bicycle frames to ensure the lightness and strength of the frames.

- Outdoor Sports Equipment: cut metal parts in outdoor sports equipment such as camping and mountaineering to provide precise size and durability.

- Hull Structural Parts: cut metal pipes in hull frames and support structures to ensure strength and corrosion resistance for offshore applications.

- Pipeline System: precision cutting of complex piping systems used in ships to meet the requirements of marine applications.

Click here to know more about:

Applications And Advantages Of Tube & Pipe Laser Cutting Machines

These application fields show that fiber laser tube cutting machines have become an irreplaceable and important tool in modern manufacturing due to their high precision, high efficiency and versatility.