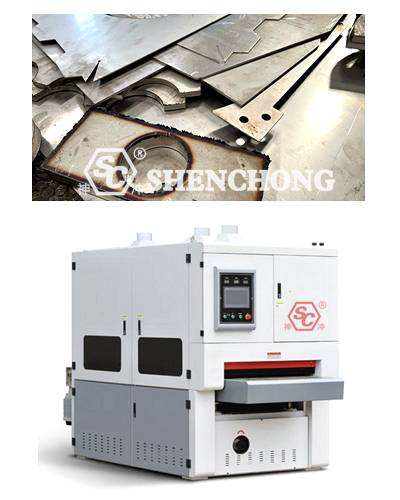

Sheet metal deburring machine is also called sheet metal grinding machine. it is used to remove burrs on the surface of rough materials. Generally, the mechanical processing industry needs deburring metal parts.

In the past, some metal materials were ground manually, which was inefficient and not clean. Wuxi Shenchong sheet metal deburring machine was developed to solve this problem. Wuxi Shenchong sheet metal deburring machine is divided into slag deburring, universal roller brush deburring, metal deburring, double-sided deburring, etc.

Sheet metal deburring machines are widely used for deburring, deflashing, chamfering, rust removal, descaling, electroplating pretreatment, and removal of knife marks on small and medium-sized precision parts. Sheet metal deburring machine also has the functions of polishing, brightening and cleaning while deburring.

It is especially suitable for deburring metal parts with complex shapes, micro precision parts, special-shaped and deformable thin arms, thin sheets, narrow slits, etc. The biggest advantage of the deburring machine is that it does not change the dimensional accuracy of the workpiece while deburring, and the appearance and feel are significantly improved. It also has the functions of polishing and brightening. After fine polishing, the surface of the workpiece can reach mirror-like brightness.

Deburring machines have been widely used in mechanical manufacturing deburring, electronic parts deburring, instrument deburring, light industry, watch parts deburring, military aerospace, textile equipment parts deburring, automotive parts deburring, bearing industry, medical equipment, precision parts deburring, powder metallurgy, metal stamping deburring, handicrafts, tools and other industries.

For small and medium-sized precision workpieces, the performance of deburring, flash removal, chamfering, rust removal, oxide removal, processing mark removal, polishing, fine polishing, mirror polishing, etc. has been significantly improved, which can completely replace or surpass expensive imported deburring and polishing equipment, many domestic production enterprises have benefited directly.

- Before operating the sheet metal deburring machine, we should wear personal protective equipment, including safety helmets, goggles, masks, earplugs and gloves, etc. These equipment can protect the head, glasses, respiratory tract, hearing and hands from injury.

- Check the power supply. This machine uses 380V with neutral wire with ground wire. Machine voltage can be customized.

- Check whether the air pressure is normal. The air supply pressure of this machine cannot be lower than 0.6MPA.

- Power on, and check whether the phase continuity is correct (the phase continuity protector displays a green light means correct, if a red light means the phase continuity is wrong).

- Replace the appropriate sanding belt.

- Press the reset button

- Use controller to adjust the distance between the conveyor belt and the sanding belt to be equal to the thickness of the plate. Then use the speed knob to adjust the conveyor belt speed.

- Start the dust collector, the conveyor rotates forward, and the first and second sets of sanding belts are turned on in sequence.

- Put the workpiece on the machine conveyor. When grinding the workpiece, we check the ammeter on the control panel. If the ammeter not have any respond when the workpiece passes the processing area of the sanding belt, it means that the workpiece has not been ground. When the workpiece passes the sanding belt, if the current is too large, it means that the grinding is too heavy. The current should be controlled within 7.5-10A. Grinding too lightly will not have a good effect on deburring and surface finishing. Grinding too heaviy will cause the thermal relay overload and stop the sanding belt motor.

- When changing different thickness plates, we need make sure to adjust the distance between the conveyor belt and the sanding belt to be the same as the plate to be processed, to prevent machine damage caused by inconsistent thickness.

- When the operation is completed, make sure all the workpieces out of the machine before turning off the machine. Turning off the machine in sequence by stopping the sanding belt motor, stopping the rotation, stopping the revolution, stopping the conveying forward rotation, stopping the electromagnetic, and stopping the dust collector.

- Clean the machine every day, and remove dust from the machine.

- We recommend customers to drain the accumulated water from the dehumidifier of the compressed air filter every day.

- Check the conveyor belt surface every month to see if it is flat. An uneven rubber surface will affect the processing effect.

- Check the surface of the sanding belt every month to see if it is flat. An uneven surface will affect the processing effect of the workpiece.

- Check the air pressure every day to ensure the belt tension.

- Check the machine parts regularly to keep them clean, well ventilated, free of dust, garbage or other residues.

- Add lubricating oil to each part according to the instructions.

for example, sheet metal deburring machine model DR1600 is a dry processing method that combines an abrasive belt grinding mechanism and a planetary deburring mechanism. It is mainly used for surface treatment of flat plates in the sheet metal industry, removal of residual burrs after machining parts, and parts produced after laser cutting.

For sintering and slag cleaning, use abrasive belt grinding and 8 grinding roller brushes (large planetary revolution, small high-speed forward and reverse rotation) to remove burrs and sharp edges on the orifice and edge of the workpiece. Use high-speed centrifugal polishing, scraping, cutting, filing and other forces on the edges and inner holes of the workpiece to remove burrs in all aspects without any impact on the accuracy of the workpiece, especially for laser cutting and CNC punching after lamination.

Sheet metal parts not only remove burrs cleanly, but also do not damage the film, and there will be no scratches on the sheet metal parts. This equipment uses special soft grinding and is only designed for the characteristics of burrs, so it is a damage to the surface of sheet metal parts (when film is applied), and it also has excellent processing efficiency for special-shaped workpieces.