Sheet metal punch presses are common stamping press, a processing machine that presses metal plates into shape. There is a fixed base and a sliding upper seat. The body of a car is punched out in one go using a powerful punch press. Also known as stamping machine or press machine.

Mostly designed as an open C-shaped body, it usually needs to be matched with molds and can process sheet metal products (a mechanical processing technique that does not change the material thickness or remove the material). It can punch, drop, punch and drop composite, bend, correct, and so on.

There are various ways to classify sheet metal punch presses.

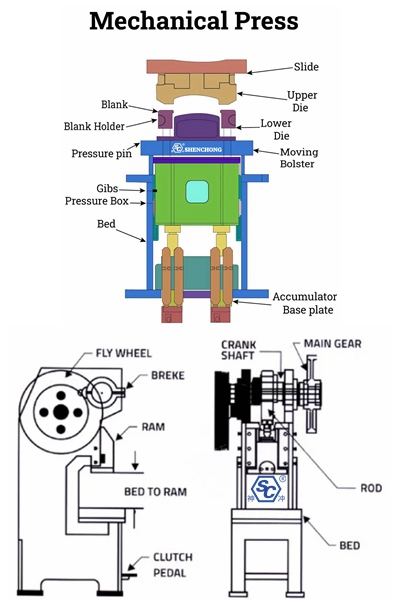

Mechanical punch press is a common type of punch press that achieves impact through traditional mechanical transmission.

Mechanical punching machines have a simple structure and are easy to operate, making them suitable for the production of small and medium-sized stamping parts.

Mechanical punching machines are divided into steel plate fixed table punching machines, open tilting punching machines, deep throat punching machines, etc.

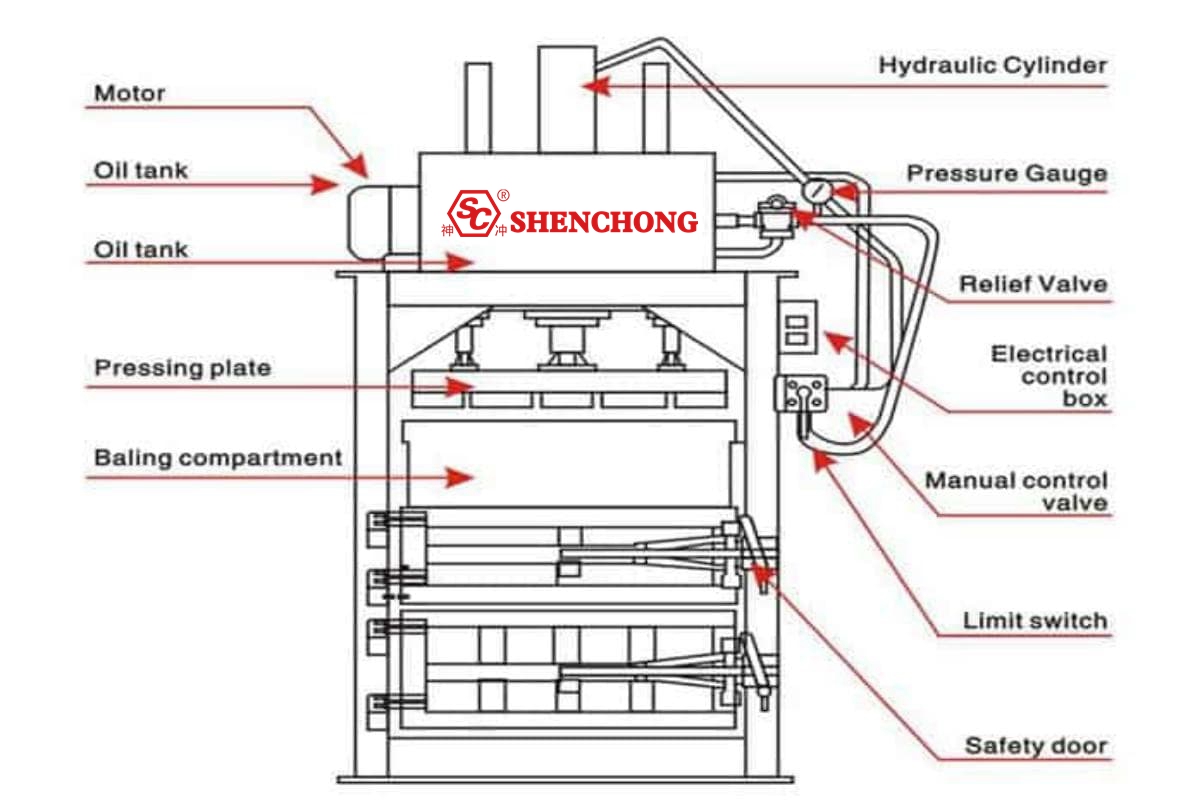

Hydraulic punch press uses hydraulic oil as the driving force to achieve impact, and its characteristics are the ability to generate high pressure and high-precision, high-speed working conditions.

Hydraulic punching machines are suitable for producing medium and large stamping parts and have a wider range of applications. Hydraulic presses are divided into C-type hydraulic presses and closed hydraulic presses (frame type hydraulic presses) according to their structure.

Pneumatic punch press uses air pressure as the impact force and has the characteristics of simple operation and affordable price.

However, due to the pressure of the gas source, which may affect the impact force and speed of the punch press, the applicability of pneumatic punch presses is relatively small, mainly used for processing smaller types of stamping parts. Pneumatic punching machines are divided into open single point pneumatic punching machines and closed double point pneumatic punching machines.

The electric punch press is driven by a motor through a reducer and achieves impact through a connecting rod and crankshaft.

The structure of electric punch press is relatively simple, without traditional mechanical transmission and hydraulic oil source. So it has significant advantages in equipment maintenance and cost. However, its impact force and speed are relatively small, making it suitable for producing small stamped parts.

A single column punch press is a worktable supported by a column that slides up and down. It has a simple structure and is suitable for cutting small-sized workpieces.

The structure of the fixed bed punch press is relatively stable, with a wide pressure range, and is suitable for cutting large-sized workpieces.

The difference between mobile bed punch press and fixed bed punch press is that the worktable of mobile bed punch press moves in the horizontal direction. Suitable for the production and processing of large quantities and small-sized workpieces.

A single punch press is a press that completes one processing action within one stroke, suitable for small batch and multi variety production and processing.

Continuous punch press completes large-scale and large-area punching of workpieces through continuous reciprocating motion, with high production efficiency.

The pressure range of small punch presses is generally below 25 tons, suitable for punching small batches, small sizes, and thinner materials.

The pressure range of medium-sized punch press is between 25 tons and 200 tons, suitable for medium-sized stamping processing.

The pressure range of large punch press is over 200 tons, suitable for punching production and processing of large workpieces.

The design principle of a mechanical punch press is to convert circular motion into linear motion, which is driven by the main electric motor to drive the flywheel.

Through the clutch, the gear, crankshaft (or eccentric gear), connecting rod, and other components are driven to achieve linear motion of the slider. The motion from the main electric motor to the connecting rod is circular motion.

There should be a transition point between circular motion and linear motion between the connecting rod and the slider. There are roughly two types of mechanisms in their design, one is spherical and the other is cylindrical, which converts circular motion into linear motion of the slider.

Mechanical punching machines apply pressure to materials to cause plastic deformation and achieve the required shape and accuracy. Therefore, a set of molds (divided into upper and lower molds) must be used to place the material between them, and the machine applies pressure to deform it. The reaction force caused by the force applied to the material during processing is absorbed by the punching machine body.

The hydraulic pump is the power source of the hydraulic punch press. Under the force of the pump, hydraulic oil enters the oil cylinder and piston cylinder through the hydraulic pipeline. Although the sealing components vary in position, they play a sealing role to prevent hydraulic oil leakage.

By using a one-way valve to circulate hydraulic oil to the oil tank, the cylinder and piston work in a cyclic manner to achieve energy conversion, regulation, and transmission, completing the cycle of various process actions.

Hydraulic cylinder: hydraulic transmission that converts hydraulic energy into mechanical energy is a transmission method that uses hydraulic pressure to transmit and control dynamic force.

Pneumatic sheet metal punch presses use high-pressure gas generated by compressors to transport compressed gas through pipelines to solenoid valves. The action of the solenoid valves is controlled by foot switches to control the operation and return of the cylinders, thereby achieving the purpose of punching holes.

Compressed air can be stored in air storage tanks and accessed at any time, so there is no energy waste from the motor idling. By using cylinders as working components and solenoid valves as control elements, the structure of pneumatic punching machines is simplified, with low failure rates, simple maintenance, and lower maintenance costs. Using a 220V power supply to control the solenoid valve is simple and convenient to operate.

Punching machines are mainly designed for sheet metal. Through molds, it is possible to produce materials such as cutting, punching, forming, deep drawing, trimming, precision punching, shaping, riveting, and extrusion parts, which are widely used in various fields.

Stamping and forming of switches, sockets, cups, cabinets, dishes, computer cases, even missile planes, electronics, communications, computers, household appliances, furniture, transportation vehicles, (cars, motorcycles, bicycles) hardware components, etc. that we use.

Do not purchase miscellaneous brands, try to choose branded machines with reliable quality and good after-sales service. No matter what problems may arise with the punching equipment in the future, it is very reliable for maintenance.

Although branded machines are more expensive than miscellaneous machines in terms of price, it is still better to choose branded machines for future peace of mind.

Don't just focus on short-term gains and ignore quality issues. Products with good quality not only use high-quality raw materials during manufacturing, but also use accessories from professional manufacturers.

These factors undoubtedly determine that the cost of producing these products is relatively high, so the price is higher than that of products with poor quality. However, when it comes to quality, the extra cost incurred during purchase seems insignificant.

It depends on the service provided by the punching machine manufacturer. Do not easily believe verbal promises. Some manufacturers always promise to solve any problems when selling products, but when problems actually arise, they hesitate to provide solutions.

Therefore, when purchasing sheet metal punch presses, it is important to see where their true service lies, rather than trusting verbal promises.