Sheet metal is a multifunctional material. It is popular for its versatility and ability to be easily processed and made into a variety of different shapes and forms. Nowadays, many common items in our life are made of sheet metal. For example, bus stops, billboards, refrigerators, lockers, etc., even as small as mobile phones, mechanical parts and accessories, etc.

All the above need cutting or bending. So, how are these products processed? Cutting sheet metal is an important link in machining.

Before making sheet metal into anything, we need to cut it to the right size, and there are many different methods. What type of metal cutting is suitable for your application? To help you make the best choice, here are some of the most commonly used metal cutting techniques and methods.

Shearing is known as die cutting. Sheet metal shearing is divided into manual and CNC.

Maual sheet metal shearing is a less precise way of cutting. CNC hydraulic plate shearing machine is the most common straight cutting tool, especially for large sheet metal. It is not for detailed metal cutting.

Plate shearing is one of the cold cutting methods. It uses blade clearance for cutting, and can also cut at a certain angle. The linear cutting accuracy of high-quality CNC plate shears is very high and there is little stress. The disadvantage is that the cutting shape is very limited and single.

Laser cutting uses a focused high-power density laser beam to cut the workpiece. Laser cutting is one of the thermal cutting methods. Therefore, it will produce thermal stress and have different effects on the later processing of sheet metal. Laser cutting is also one of the most intensive and expensive methods of cutting sheet metal.

The advantages are high efficiency, high speed, clean and safe. Laser cutting is also very flexible and can cut different shapes at will. But the price of a laser cutting machine is very high, usually in millions. And there is no special advantage for linear cutting. Generally, laser cutting processes 2-6mm sheets. Cuts above 10mm are rare.

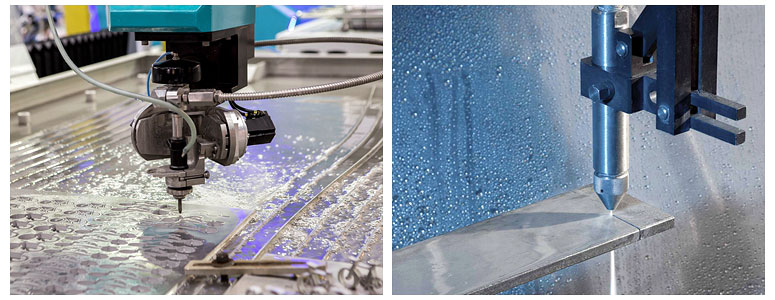

Water cutting, also known as water knife, that is, high-pressure water jet cutting technology, is a machine that uses high-pressure water flow to cut.

Low cost and easy operation are the reasons for its popularity. It is cold cut and does not produce thermal deformation or thermal effects. Generally speaking, materials with complex patterns, thick, difficult to cut, fragile and afraid of heat are most suitable for water jet cutting as processing equipment. This method allows precise metal surface treatment.

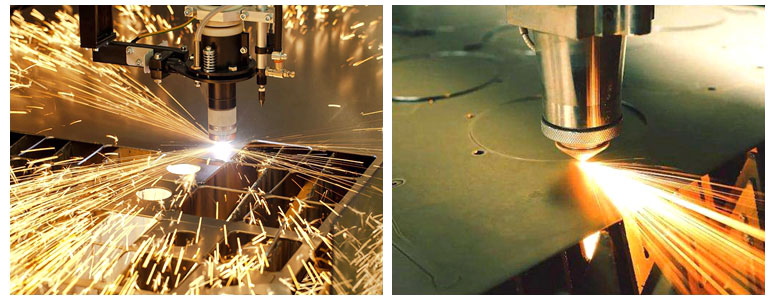

Plasma arc cutting is a machining method that uses the heat of high-temperature plasma arc to form a notch. This cutting process is better for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel). It is thermal cutting and also produces stress.

Plasma is a relatively new metal cutting method. Plasma cutting is fast, but not as fast as laser cutting. Plasma cutting can process sheets up to 30mm thick, which is wider than laser cutting sheet metal.

Flame cutting is a common way of rough machining of steel plate. Flame cutting is gas cutting. The traditional is to use acetylene gas for cutting, and later to use propane. Now there is natural gas cutting. And because of its abundant reserves, low price, and no pollution, natural gas has become the first choice for flame cutting.

Flame cutting is the oldest thermal cutting method. Compared with plasma, the heat affected zone of flame cutting is much larger. The thermal deformation is very large. In order to cut accurately and effectively, operators need to have superb technology to deal with the problem of deformation.

Flame cutting equipment has low cost and is the only economical and effective means to cut thick metal plates. However, there are obvious shortcomings in thin plate cutting. Its cutting metal thickness ranges from 1mm to 1.2m. Generally, only relatively thick large metal plates can be used, and are limited to rough processing of cutting sheet metal.

The above are the five most commonly used sheet metal cutting methods. Sheet metal has different thickness and properties. According to the shape and type of sheet metal, you can choose the appropriate cutting equipment or use several different equipment.

To sum up, different sheet metal cutting methods are suitable for different metal materials and technical levels. When choosing a metal cutting method, you need to consider factors such as equipment cost, cutting speed, and cutting quality. No matter which cutting method is used, professional operators are required to operate it to ensure the safety and stability of the cutting process. Of course, as an enterprise, we also need to consider productivity and cost! How to get the balance and buy the best equipment is worth pondering.