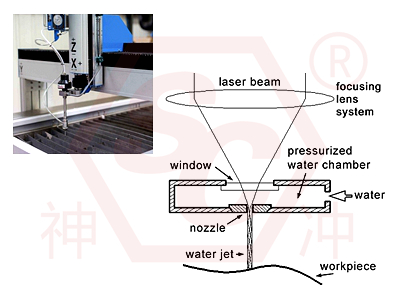

A CNC water jet cutting machine is a machine that uses high-pressure water flow for cutting. The water cutting machine uses high-pressure water jet cutting technology.

Under the control of a computer, work pieces can be arbitrarily carved with minimal influence from material texture. Due to its low cost, easy operation, and high yield, water cutting is gradually becoming the mainstream cutting method in industrial cutting technology.

Water jet cutting technology, also known as high-pressure water jet cutting technology, uses water as the cutting tool. This technology originated in the United States and was used in the aerospace military industry.

It is highly favored because its cold cutting does not alter the physical and chemical properties of the material. After continuous technological improvement, abrasives such as garnet sand and diamond sand were mixed in high-pressure water to assist in cutting, greatly improving the cutting speed and thickness of the water jet.

CNC waterjet cutting machine for sale have been widely used in various industries such as ceramics, stone, glass, metal, composite materials, etc. In China, the maximum pressure of the water jet has reached 420MPa. Some technologically advanced companies have improved their 3-axis and 4-axis water knives, while 5-axis water knives are also becoming more mature.

Water jet cutting machine is a planar cutting machine tool that combines a high-pressure water jet generator with a two-dimensional CNC machining platform. It increases the pressure of the water flow to a sufficiently high level (above 200MPal), allowing the water flow to have kinetic energy that can penetrate chemical fibers, wood, leather and rubber, etc. Mixing a proportion of abrasive in a high-speed water flow can penetrate almost all hard materials such as ceramics, stone, glass, alloys, etc.

Water jet cutting can perform a one-time cutting process on any material with any curve (except for water jet cutting, other cutting methods will be limited by the material variety).

The heat generated during cutting is immediately carried away by the high-speed flowing water jet and does not produce harmful substances. The material has no thermal effect (cold cutting). No need or ease of secondary processing after cutting.

Safe, environmentally friendly, fast, and efficient. It can achieve cutting and processing of any curve. Convenient, flexible, and versatile. Water cutting is a mature cutting process method with good applicability.

CNC water cutting machines are superior to other processing technologies, such as flame cutting, plasma processing, laser processing, electric discharge machining, turning and milling machining, etc. At the same time, water cutting does not generate harmful gases or liquids, and does not generate heat on the surface of the work piece. It is truly multifunctional, efficient, and cold cutting processing.

(1) The roughness of cutting metal reaches 1.6 μ m. The cutting accuracy reaches ± 0.10mm. Can be used for precision forming cutting.

(2) There is no reflective effect or edge loss in the cutting of non-ferrous metals and stainless steel.

(3) Carbon fiber composite materials, metal composite materials, metal composites with different melting points, and non-metallic one-time forming cutting.

(4) Cutting of low melting point and flammable materials, such as paper, leather, rubber, nylon, felt, wood, explosives, etc.

(5) Cutting in special locations and environments, such as underwater or environments with combustible gases;

(6) Cutting of high hardness and insoluble materials, such as stone, glass, ceramics, hard alloys, diamonds, etc.

- High pressure water pump (the core equipment that produces high-pressure water)

- CNC motion control platform

It is abbreviated as a processing platform, which is equivalent to a large three-axis end mill. The table where the work piece is placed is just a water tank. Fill the water tank with water to alleviate the impact of high-pressure water injection.

- Abrasive storage and transportation system

- Switching water control system

Water cutting is divided into two methods: sand free cutting and Gaza cutting.

It is divided into large water cutting and small water cutting.

It is divided into high-pressure type and low-pressure type, generally with a limit of 100MPa. Above 100MPa is a high-pressure type, and below 100MPa is a low-pressure type. And above 200MPa is an ultra-high pressure type.

It is divided into front mixed and rear mixed.

It is divided into cantilever style and gantry style.

It is divided into safety cutting and non safety cutting, with the main difference being in water pressure. Low pressure water cutting below 100MPa can be applied to special industries such as hazardous chemicals, petroleum, coal mines, and hazardous material handling.

After a large number of experiments, it has been found that when the water pressure exceeds a certain threshold, even pure water can detonate certain sensitive chemicals. However, when cutting water containing sand, the potential energy and impact force of sand and objects collide in the water can also cause instability of special chemicals. After extensive experiments and argumentation, it has been concluded that the threshold is around 237.6MPa. Therefore, in the water cutting industry, people mainly apply water cutting above 200MPa in the mechanical processing industry.

In addition to cnc water jet cutting machines, there are also CNC hydraulic shearing machine, laser cutting machines, plasma cutting machines, flame cutting machines, and so on.

Click here to know: Common Methods of Cutting Sheet Metal [5 Ways]

In metal cutting, various processing methods coexist, including cutting tools, laser, flame cutting (plasma cutting), electric discharge, wire cutting, water cutting, and other processing methods. Various cutting methods have their own advantages and limitations, each occupying a portion of the market.

Users can choose the most suitable equipment for their production based on their different needs and budgets!