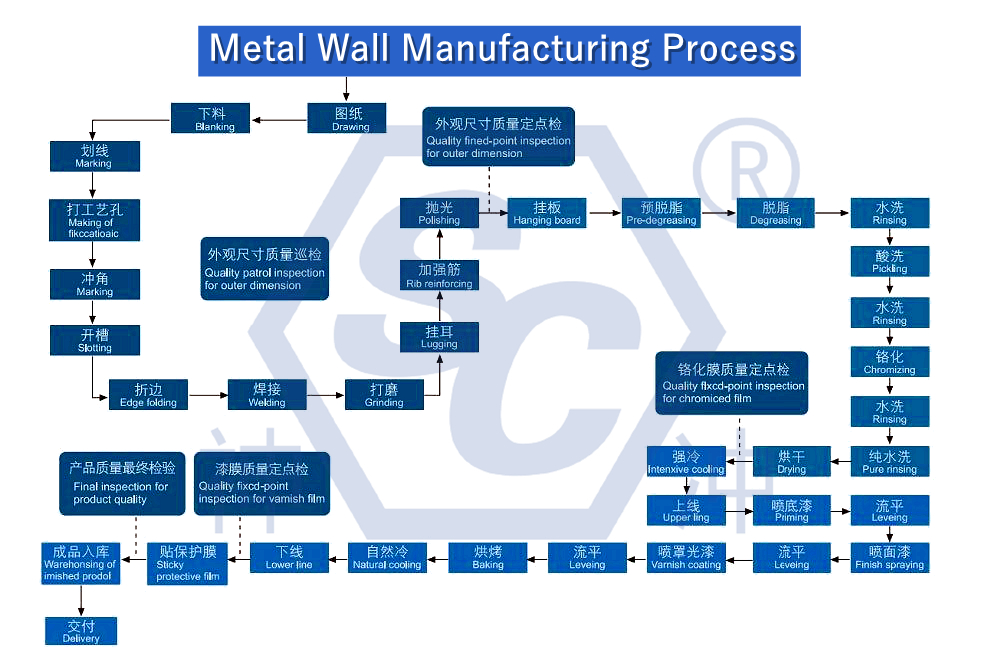

With the rapid development of the economy, large public buildings and high-rise buildings have developed rapidly. As a material characterized by lightweight, thin, large surface, and exquisite appearance, metal curtain walls have been rapidly applied in various fields of buildings. The metal curtain wall processing includes cutting, punching, grooving, bending, welding, polishing, corner coding, polishing, cleaning, air drying, spraying and coloring, and so on.

Before the production of the curtain wall, the design and construction drawings of the building should be checked, and the building should be retested. The deviation in the curtain wall drawings should be adjusted based on the measured results, and can only be processed and assembled with the consent of the design unit.

When using sealant to bond fixed components, the injection should be carried out at a temperature of 15 ℃ to 30 ℃, and in a clean and ventilated room with a relative humidity of over 50%. The width and thickness of the adhesive should meet the specified requirements.

The processing and production of curtain wall components should meet the design and specification requirements in terms of size. The surface rust prevention treatment of metal components should comply with the relevant provisions of current national standards.

Ordering, cutting, punching, grooving, bending, welding, polishing, corner coding, polishing, cleaning, air drying, spraying and coloring, packaging and shipment, and on-site installation.

Cutting equipment, CNC turret punch machine, CNC grooving machine, CNC bending machine, CNC engraving machine, welding equipment, deburring machine, spraying production line, etc.

Firstly, select the raw materials. The variety, specifications, and color of metal plates should meet the design requirements. The surface coating thickness of alloy plates should meet the requirements.

Then, proceed with the processing of the sheet metal. Apply a laser cutting machine or CNC plate shearing machine to cut the board and cut it into appropriate sizes. Drilling, punching, and slotting are being carried out.

In order to enhance the aesthetics of bending, the construction and decoration industry will also purchase CNC v grooving machines for slotting processing before bending. After V-groove machining, bending will be easier and more attractive.

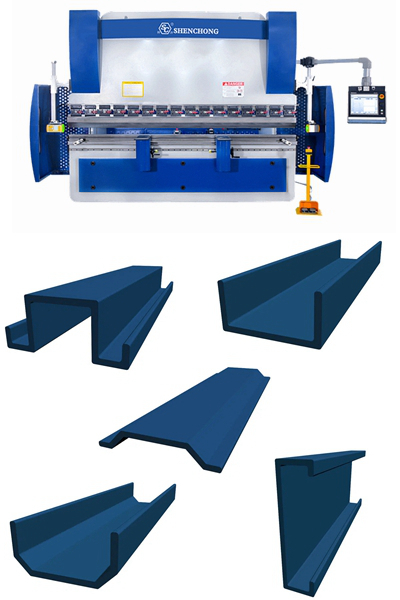

The most important step is to use a CNC press brake machine to process the plate into the desired shape.

125ton 6000mm CNC hydraulic press brake 4+1axis with ESA630

- During the bending process, we need to clean the debris at the bending point of the curtain wall panel.

- Do not perform repeated or rapid bending to prevent the metal curtain wall panel from being damaged and reducing its strength.

- After the CNC press brake machine is completed, the four corners of the board should be sealed with sealant for docking.

The next step is to weld, grind, polish, clean, and air dry the processed sheet metal. In this way, the metal plates of the curtain wall are basically processed. Finally, only spray painting, coloring, and leveling post-processing are required.

Metal curtain wall is a new type of building curtain wall used for decoration. Curtain wall is the outer wall enclosure of a building, which is a commonly used lightweight wall with decorative effects in modern high-rise buildings.

It consists of a panel and support structure system. Compared to the main structure, the metal curtain wall has a certain displacement capacity or its own deformation capacity, and does not bear the role of the main structure in the external enclosure or decorative structure of the building.

Architectural metal cladding curtain walls are commonly used for the peripheral protective structures of office buildings, commercial buildings, sports venues, exhibitions, cultural facilities, transportation hub buildings, etc.

Outdoor curtain walls, indoor suspended ceilings, outdoor ceilings, indoor walls, halls, corridors, balconies, background walls, light troughs, curtain boxes, wrapped columns/beams, floating roofs, gardens, elevators/stairs, front desk/porch, door heads, bedrooms/rooms, windows, and more.

Commercial buildings, airports, high-speed trains/stations, subways, sports venues, schools, parks, conference rooms, villas, office buildings, hospitals, administrative buildings, exhibition halls, tunnels, homes, opera houses, hotels, clubs, banks, factories, workshops, shopping malls, restaurants, transportation vehicles, libraries, computer rooms, basements, parking lots, breeding grounds, overpasses, sidewalks, toll stations, gas stations, facade signs, etc.