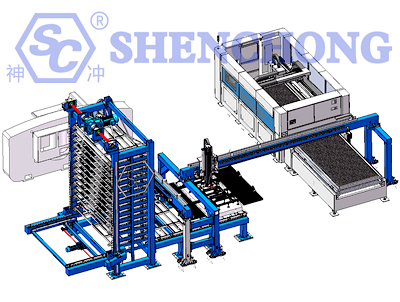

With the progress and development of science and technology, simple manual operation can no longer meet the needs of enterprises for production, the automation process has become the excessive direction of enterprises. CNC Punch Press Loading and Unloading System can not only improve production efficiency, but also replace workers to complete high-intensity and monotonous work, reduce workers' labor intensity and reduce production costs. Therefore, it has been trusted and concerned by manufacturers.

The CNC punch is a high-precision, efficient and high-stability punch equipment that can process a variety of special-shaped parts and holes. Compared with traditional mechanical punch presses, CNC turret punch machine have the advantages of high automation, high precision, and high stability.

For companies that need to produce special-shaped parts in large quantities, CNC punching machines are also widely used in industries such as bank cards, solar photovoltaic panels, home appliances, auto parts, and engineering machinery.

CNC punching machine is a mold type processing equipment with the characteristics of convenient and fast mold replacement, suitable for a certain number of production and processing.

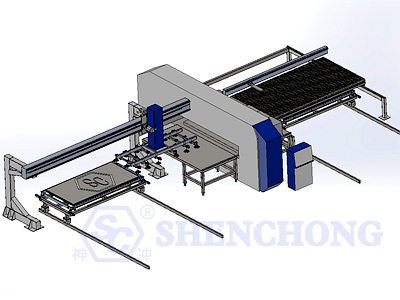

The automatic punching machine loading and unloading system operates synchronously, reducing the waiting time of the punching machine and improving the utilization rate of the equipment.

The CNC system of CNC punching machines can control the operation process. Through the process detection function, it is possible to detect all abnormal situations in the production process, prevent and correct abnormalities as early as possible, and improve production efficiency.

The CNC turret punching machine adopts a high-precision control system, which can accurately control various parameters and process flows during the machining process, ensuring that the quality of the processed products meets customer needs.

CNC punch press machines can provide multiple processing services, such as perforation, cutting, embossing, splicing, X-shaped cutting, etc. By adapting to different customer needs through various processing methods, it increases the flexibility of processing and greatly meets the production needs of different industries.

The maintenance cost of CNC punching machines is low, and the maintenance and upkeep of parts are simple, which can ensure stable production at different time periods, reduce equipment failure rate and downtime maintenance time.

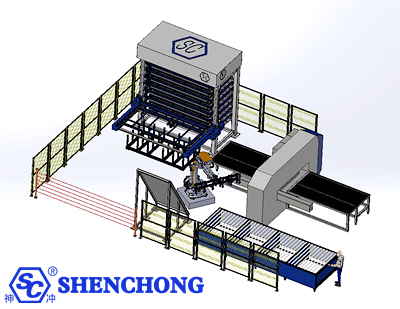

Automatic production system real-time monitoring of work progress, comprehensive control of machine information, more convenient maintenance.

The CNC punching machine with automatic loading and unloading system adopts a high-level safety control system. Equipped with brake anti misoperation device, safety hook, safety switch and other equipment to ensure the safety of the processing operation process.

The CNC punch press loading and unloading machine adopts an automation control system, which can control the working panel and make the working process more automated. Reduce the burden on operators and improve work efficiency.

The sheet metal CNC turret punching machine automatic loading & unloading equipment realizes the automatic loading and unloading of CNC punching plates on the side, replacing manual work to achieve 24-hour uninterrupted work, greatly reducing the heavy manual tasks.

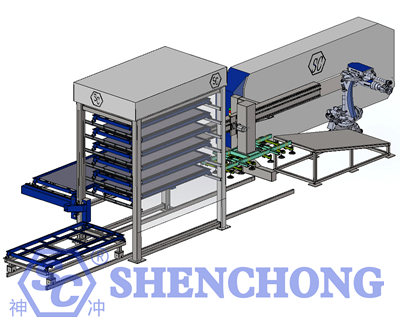

The automated silo is a powerful extension of the punching sheet metal processing system, which doubles the production efficiency of customers, reduces the beat time of independent units, and saves land area.

Due to the high cost of manual operation, difficulty in controlling quality, and low production efficiency, modern production enterprises will adopt automated production methods. This not only meets the requirements of enterprises for products, but also reduces their labor costs.