SHENCHONG WEK 63Tons 2500mm cnc press brake machine with ESA S630 Controller, 4+1 axis.

The fuselage adopts integral welding and integral processing structure.

Adopting the closed-loop control method composed of German electro-hydraulic servo valve and grating ruler, the slider position feedback accuracy is high, the operation is accurate and stable, the synchronization performance is good, and the bending accuracy is high.

The numerical control system can realize the functions of bending angle graphic programming, angle correction compensation,automatic calculation and automatic adjustment of bending pressure, automatic calculation of the deformation compensation amount of the worktable, the unfolded length of the work piece, and the automatic back gauge of the back gauge.

ESA S630 controller controls the backgauge, which can continuous bend the complex workpiece

Nominal Pressure: 63 Tons

Length of Table: 2500mm

Distance Between housings: 2000mm

Throat Depth: 320mm

Stroke: 160mm

Open Height: 400mm

Main Motor: 7.5kw

Approach speed: 180mm/s

Axis(4+V): Y1, Y2, X, R +V

Y1,Y2 parallel tolerance: ±0.01mm

X precision: ±0.015mm

X movable distance: 5-1000mm

R precision: ±0.03mm

R movable distance: 200

Overall Dimensions: 3040x1640x2225mm

Weight: 4.8 Tons

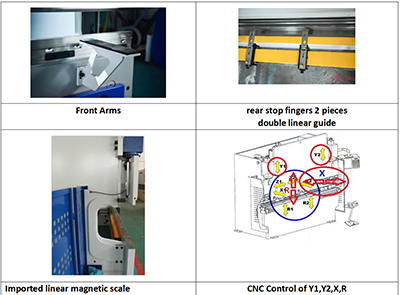

CNC axis description:

Y1, Y2 axis—controls the CNC axes of the cylinders on both sides. The X-axis controls the back gauge and forth of the back gauge, the R-axis controls the back gauge up and down, the Z1,Z2 axis control the back gauge finger left and right, and the V-axis table is CNC crowning.

Movable front arm support

Double linear guide of the backgauge

2 pieces standard rear stop fingers

Linear magnectic scale from German

Standard 4 axes controlled by CNC

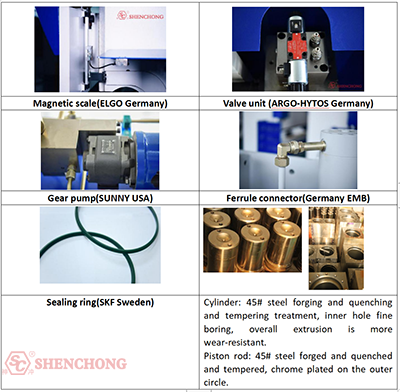

Magnetic scale (ELGO Germany)

Valve unit (ARGO-HYTOS Germany)

Gear pump (SUNNY USA)

Ferrule connector (EMB Germany)

Sealing ring (SKF Sweden)

ESA S630 CNC controller (Touch Screen from ESA Italy)

Main motor (SIEMENS)

V axis table crowning (CNC controlled)

Backgauge servo motor (DELTA Taiwan)

Electrical components (Schneider France)

Movable foot pedal for esay operation and emergency power off function

As a professional CNC press brake machine manufacturer, Shenchong always focus on customers' satisfaction.

We will arrange for engineers and installers to go to the site for installation, commissioning and training, which is about 3 days. Or you can arrange for people to come and study.

The warranty period of the machine is 13 months, including one month in shipping.

If there is any problem, we will first check the machine problem through video and guide the repair. If it still cannot be solved, an employee will be sent to the site for repair.

During the warranty period, non-human damage, parts damage shall be responsible by the seller.