The metal sheet deburring machine magnetic type is a device specially used to remove burrs on the edges of metal sheets.

- Adopts magnetic adsorption method

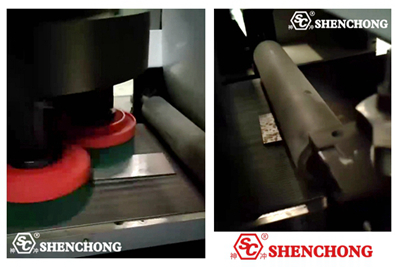

The magnetic deburring machine uses the magnetic field generated by the magnet to adsorb the magnetic abrasive disc on the metal surface to be processed. Then the machine drives it to rotate, and the abrasive grains of the abrasive disc continuously rub against the metal surface to remove burrs and scratches.

The magnetic deburring mothod is very effective in removing burrs, scratches and oxide scale, and the removal effect is obvious.The operation and maintenance are simple and convenient. The equipment cost is relatively low.

- Affordable price sheet metal deburring machine for sale

- The width of sheet metal deburring machine is 350

- Deburring of small workpieces by laser cutting

The magnetic sheet metal deburring machine uses magnetic transmission technology to drive specific abrasives or deburring tools (such as steel needles and steel balls) to contact the surface of metal sheets through the magnetic force generated by electromagnetic or permanent magnets. Under the action of magnetic force, the abrasive rotates at high speed and contacts the edge of the sheet at different angles, thereby effectively removing burrs. This method is very suitable for processing precision parts and workpieces with complex shapes.

Magnetic deburring machines for sale are widely used in various metal materials, including but not limited to:

- Stainless steel

- Aluminum alloy

- Steel plate

- Copper plate

It is particularly suitable for deburring thin sheets because it can effectively remove edge burrs without damaging the surface of the workpiece or changing the shape of the workpiece.

Since the working mode of the magnetic deburring machine does not impose excessive mechanical stress on the sheet, deformation or surface damage of the workpiece can be avoided.

The magnetic deburring machine has a fast processing speed and is suitable for large-scale production scenarios.

Whether it is an inner hole, an outer corner, or a complex curved surface structure, the magnetic deburring machine can effectively cope with it.

Many magnetic deburring machines are equipped with automated control systems, which can achieve unattended operation and further improve production efficiency.

Magnetic deburring machines are widely used in many industries, including:

Aerospace: Used to remove burrs from aircraft parts to ensure the precision and safety of parts.

Automobile manufacturing: In the production of automotive parts, it is used to remove burrs from various metal parts and improve the assembly accuracy of parts.

Electronic manufacturing: Especially in the production of electronic components that require high precision, magnetic deburring machines can effectively remove fine burrs and ensure product quality.

Although magnetic sheet metal deburring machines are suitable for most metal sheets, preliminary testing is required for some materials with particularly high hardness or special surface treatment.

According to different workpiece materials and deburring requirements, it is very important to choose the right abrasive to achieve the best deburring effect.

Regularly check the magnetic system and abrasive status, and perform maintenance in time to ensure the long-term stable operation of the equipment.

Click here to know more about:

Magnetic Deburring Polishing Machine Operation & Application

As the manufacturing industry has higher requirements for product precision and surface quality, the demand for magnetic deburring machines for sale in the market has gradually increased, especially in high-end manufacturing, where its application prospects are very broad. In the future, with the continuous advancement of technology, magnetic deburring machines will further develop in the direction of high efficiency, environmental protection, and intelligence.

In general, SC sheet metal deburring machine for sale is an efficient, precise and widely used equipment, especially suitable for scenes with high requirements for workpiece surface quality in modern manufacturing.