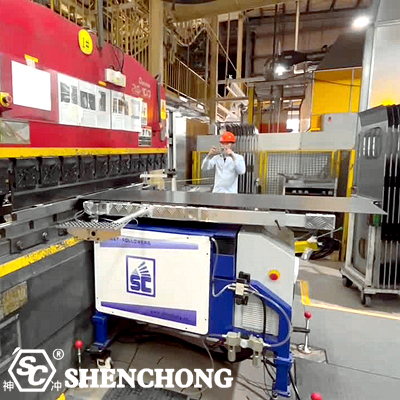

Kubota China Holdings Co.,Ltd. ordered a CNC press brake bending follower device from us. On-site technicians have completed debugging.

Kubota China Holdings Co.,Ltd. is a Sino-foreign joint venture that manufactures agricultural machinery and equipment. Agricultural machinery includes combine harvesters, rice transplanters, tractors, small construction machines, small diesel engines, cast iron pipes, etc. A large number of metal sheets will be used in the manufacturing process of this type of equipment, which requires the use of CNC press brake machines, metal cutting machines, etc.

The main function of cnc press brake bending follower device is to assist the bending machine in its work. Reduce the work intensity of operators, improve bending efficiency and promote production.

The Best Price US$5,000! Bigger discounts for larger quantities!

The working principle of the bending follower support device mainly includes the following aspects.

When the bending machine starts working, the follower support device senses the movement and position of the bending machine through sensors or encoders.

The control system receives data from the sensor and adjusts the position and height of the support device in real time according to the operation of the bending machine.

The follower support device is synchronized with the movement of the bending machine. When the tool of the bending machine descends for bending operation, the support device rises or moves accordingly to support and follow the changes of the material.

This synchronous movement ensures the stability of the material during the bending process and prevents the material from sagging or moving due to its own weight or bending force.

Using servo motors and precision guide rails, the follower support device can achieve high-precision positioning in the vertical and horizontal directions.

The control system accurately adjusts the position of the support device according to the preset program and real-time data to ensure that the material is always in the correct support position.

The bending follower support device is equipped with a feedback system that can monitor its position and status in real time and feed back the data to the control system. The control system makes dynamic adjustments based on the feedback data to ensure that the follower support device always maintains the best working condition.

In order to ensure safe operation, the bending follower device is usually equipped with a safety sensor. When an abnormal situation (such as material slipping or equipment failure) is detected, it can automatically stop the operation and sound an alarm to prevent accidents.

The bending follower support device senses the operating status of cnc hydraulic press brake machine and adjusts the support position in real time to achieve synchronous movement and precise positioning with the bending machine. It provides stable material support, improves the accuracy and efficiency of the bending process, and ensures safe operation.

The bending follower support device is an auxiliary device used in the bending machine. Its main functions are as follows:

During the bending process, the follower support device can provide support for large-sized or heavy materials to prevent the material from bending or deforming due to its own weight.

By stabilizing the position of the material and reducing the movement of the material during the bending process, the accuracy and consistency of the bending process can be improved.

Reducing the workload and intensity of workers' manual support, especially when handling large-sized or heavy materials, can significantly reduce the burden on operators.

Avoid friction between the material and the work surface or other equipment during the bending process, and reduce the occurrence of scratches or other surface damage.

Through automated support operations, the speed of bending processing can be accelerated and the overall production efficiency can be improved.

The characteristics of the bending follower support device include:

The bending follower support device is usually equipped with an automated control system, which can automatically adjust the support position according to the operation of the bending machine, achieve synchronous movement and positioning, and improve work efficiency.

Through precise sensors and servo systems, the bending follower support device can achieve high-precision material positioning and support, ensuring accuracy and consistency during the bending process.

The device can adapt to materials of different sizes, shapes and weights, and can flexibly adjust the support position and angle to meet various bending needs.

The design is sturdy and durable, and can operate stably for a long time, reduce maintenance requirements, and extend the service life of the equipment.

By reducing the need for manual support, the labor intensity and risk of injury of operators are reduced, and the safety of the working environment is improved.

Some bending follow-up support devices also have easy-to-operate interfaces and humanized designs, making operation easier and reducing operating errors.

The characteristics of automation and high precision enable the bending follow-up support device to significantly improve production efficiency, reduce production cycle and processing time.

Reduce the loss of materials caused by improper operation or unstable support during the bending process, and improve material utilization.

These features make the bending follow-up support device widely used in modern manufacturing, especially in fields that require high-precision and high-efficiency production.