The metal edge rounding machine is a professional steel processing equipment. It is mainly used to deal with burrs and welding slag on the surface or inside of steel. It makes the surface of steel smoother and improves the mechanical properties and surface quality of steel.

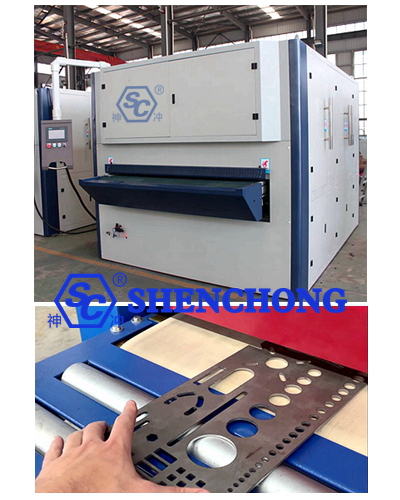

Deburring edge rounding machine equipment is generally composed of worktable, working axis, cutting tool, positioning system and drive system. Among them, the working axis is the core component of deburring machine equipment, which is responsible for driving the cutting tool to perform cutting operations.

The drive system of edge deburring machine equipment is usually driven by a motor. And it can convert the rotational torque output by the motor into the linear motion of the working axis through different transmission mechanisms to complete the cutting operation.

At the same time, the drive system of the rounding machine equipment also has functions such as speed regulation and direction control to meet the cutting requirements of different workpieces.

The deburring rounding machine equipment mainly drives the rotation of the cutting tool through the working axis, and then the cutting edge of the tool and the surface of the workpiece produce a shearing effect to achieve the purpose of removing burrs on the surface of the workpiece.

The precision and material of the cutting tool have an important influence on the burr removal effect. Therefore, when selecting a cutting tool, it is necessary to make a comprehensive consideration based on the actual situation.

With the development of high technology and the improvement of product performance, the requirements for product quality are becoming more and more stringent, and it is more important to remove burrs from mechanical parts.

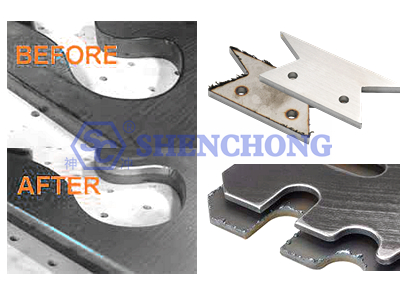

Deburring refers to the removal of fine metal particles on the surface of the workpiece, which are called burrs. They are formed during cutting, grinding, milling and other similar cutting processes.

The application scenarios of deburring machine equipment are very wide, and can be used for the processing of materials such as metal products, plastic products and rubber products. The edge rounding deburring equipment can not only improve the finish and quality of the workpiece surface, but also greatly shorten the processing cycle and greatly improve production efficiency. At present, the deburring equipment has become one of the necessary equipment for many manufacturing enterprises.

- Precision stamping parts

- Stainless steel parts

- Screws and nuts

- Magnesium-aluminum die-cast parts

- Zinc-aluminum die-cast parts

- Precision springs and shrapnel parts

- Electronics, computers, and communication parts

- Medical equipment, automobiles, and aerospace precision parts

The metal sheet edge rounding machine is a device specially used to remove burrs on the surface of metal materials and is widely used in the manufacturing industry. Its main feature is that it can remove burrs efficiently, which greatly improves the surface smoothness and aesthetics of metal products.

- Precision grinding to remove burrs from inner holes of workpieces

- Removal of oxide films

- Polishing of finished oily surfaces

- Rust removal

- Treatment of sintering blackening marks

- Grinding and cleaning work in the gold jewelry industry

- Removal of burrs from small gaps

If there are burrs on a flat part, the burred surface will be used for positioning or assembly with other parts, resulting in inaccurate dimensions. If a shaft part has burrs (such as no chamfer), it will not fit in the hole when it is precisely matched with it. Forcing it in will also prevent it from rotating flexibly in the hole, and even scratch the surface of the hole.

Burrs and sharp corners can easily cause parts to rust and are stress concentration points. Therefore, we need to perform deburring when processing metal. Compared with traditional manual deburring methods, deburring machines can greatly improve deburring efficiency, reduce labor and time costs, and thus improve production efficiency.

The deburring machine can remove burrs on the outer surface of steel, making the surface smoother and smoother, and improving the quality and aesthetics of the steel surface. In the manufacturing process, removing burrs on the outer surface can avoid damage to the steel surface, reduce surface problems such as surface fatigue strength and surface roughness, thereby improving the performance and safety of the steel.

The deburring edge rounding machine can also be used to remove undesirable substances such as welding slag and oxides inside the steel, remove internal burrs, make the inside of the steel cleaner and tidier, and improve the structure and mechanical properties of the steel.

The edge rounding machine can quickly remove burrs and welding slag on the surface and inside of the steel, reduce the manual cleaning of burrs and welding slag by processing personnel, and greatly improve production efficiency and work efficiency.

In the manufacturing process, manual cleaning of burrs and welding slag requires a lot of manpower and time, and the use of the deburring machine can quickly remove burrs and welding slag on the steel, improve production efficiency while saving costs, and reduce manufacturing costs and production costs.

The use of the edge deburring machine can effectively remove burrs and welding slag on the surface and inside of steel, making the surface of the steel smoother, without burrs, corners, and sharp edges, avoiding safety problems and surface problems caused by the presence of burrs and welding slag, and improving the overall quality and performance of steel.

Deburring machines are widely used for deburring, edge rounding, chamfering, rust removal, descaling, electroplating pretreatment, and removal of processing knife marks on small and medium-sized precision parts.

Deburring edge rounding machines have the functions of polishing, brightening, and cleaning while deburring. It is particularly suitable for the difficult problem of deburring parts with complex shapes, micro-precision parts, special-shaped and deformable thin arms, thin sheets, narrow slits, etc.

The biggest advantage of the sheet metal edge rounding deburring machine is that it does not change the dimensional accuracy of the workpiece while deburring, and the appearance and feel are significantly improved. It also has the functions of polishing and brightening. After fine polishing, the surface of the workpiece can reach mirror brightness.

In short, deburring machines have been widely promoted in the mass production and processing of small and medium-sized parts, completely replacing the backward traditional deburring process, and significantly improving the efficiency and benefits of deburring. The metal edge rounding machine deburring equipment has the advantages of simple structure, easy operation, and high efficiency.

The deburring machine is a very important equipment in industrial production and plays a pivotal role in modern manufacturing. Understanding the basic knowledge and operation of the deburring machine can better help enterprises to process steel and improve production efficiency and product quality.

Click here to know: