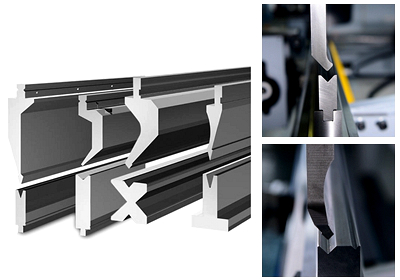

To ensure the press brake tooling quality, the first thing to do is to design reasonably and choose the best structural scheme as far as possible. The punch and die manufacturer shall consider the technical requirements and structure of the parts must conform to the manufacturability and feasibility of the mold.

Reasonable design is the most important step to improve the quality of the bending tools.

There are many factors that need to be considered, including:

- Material selection

- Usability of structure

- Safety

- Machinability

- Convenience of maintenance

All of the above should be taken into consideration at the beginning of the design.

The selection of press brake tooling materials should not only meet the customer's requirements for product processing, but also take into account the manufacturing cost and strength within the set cycle.

Of course, the materials shall be selected according to the type, use, working mode, processing speed, main failure forms and other factors of the bending machine.

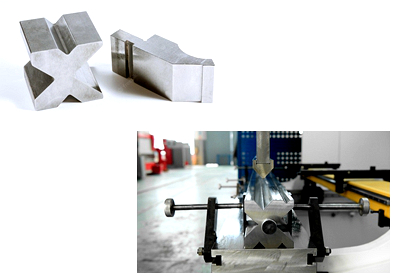

When designing the tools, try to ensure that the structure is compact and the operation is convenient, and also ensure that the bending machine die parts have sufficient strength and stiffness.

If the structure allows, the corners of each surface of the tooling parts shall be designed as fillet transition as far as possible to avoid excessive stress concentration. For the female die, cavity and part of the male die and core, the combined or inlaid structure can be used to eliminate the stress concentration. The slender punch or core shall be structurally protected properly.

At the same time, we should also consider how to reduce the impact on the quality of press brake tooling caused by the wear of sliding fit parts and frequent impact parts in long-term use.

In the design, the scope of disassembly and assembly required for maintenance of a certain component must be reduced. In particular, the scope of disassembly and assembly shall be reduced as much as possible when the wearing parts are replaced.

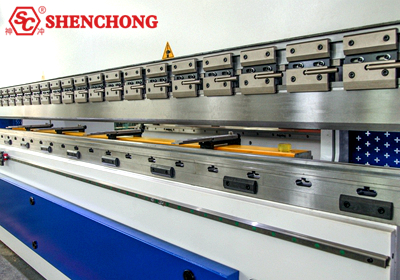

The manufacturing process is also an important part of ensuring the quality of CNC bending machine molds.

The processing method and precision in the manufacturing process will also affect the service life of the press brake die. The accuracy of each component directly affects the overall assembly of the bending machine mold.

In addition to the influence of the accuracy of the equipment itself, it is necessary to improve the processing accuracy of the mold parts of the bending machine by improving the processing method of the parts and improving the technical level of the fitter in the grinding and matching process.

If the overall assembly effect of the bending machine mold does not meet the requirements, the error of the bending processing will increase in the trial mold, which will have a great impact on the overall quality of the CNC press brake work.

In order to ensure that the tooling has good original precision and quality, first of all, it is necessary to reasonably select high-precision processing methods, such as EDM, wire cutting, CNC machining and so on.

At the same time, should pay attention to the inspection of mold accuracy, including the machining accuracy of mold parts, assembly accuracy, and comprehensive inspection of the accuracy of the bending machine through mold trial acceptance.

In the inspection, it is also necessary to use high-precision measuring instruments as much as possible. For those mold parts with complex surface and curved structure, accurate measurement data cannot be achieved with ordinary rulers and vernier cards. At this time, it is necessary to use precision measurement equipment such as a three-coordinate measuring instrument to ensure the accuracy of the measurement data.

The surface of press brake tooling is strengthened to improve the wear resistance of the surface, so as to better improve the quality of tool. For surface strengthening, we should choose different strengthening methods according to different molds for different purposes.

For example, the blanking die can adopt electric spark strengthening, hard alloy surfacing, etc. to improve the wear resistance and compressive strength of the surface layer of the die parts.

Nitriding (hard nitriding) treatment can be used for hot working bending machine die steel parts such as die-casting die and plastic die to improve the wear resistance, heat fatigue resistance and corrosion resistance of the parts.

The drawing die and bending die can be treated by sulfurizing to reduce the friction coefficient and improve the wear resistance of the material. Carbonitriding (soft nitriding) can be applied to the surface strengthening treatment of various molds

The correct use is also a major factor in improving the quality of the press brake tool. In addition to proper use, regular maintenance of the mold is also required. For example, the parts of the mold that need to be moved should be frequently filled with lubricating oil.

Perform planned preventive maintenance. Through data statistics in the maintenance process, we can effectively prevent possible problems in production and improve the efficiency of maintenance work.

In a word, in order to improve the quality of the bending machine die, we must consider every link, including design, manufacturing, assembly, use and maintenance.