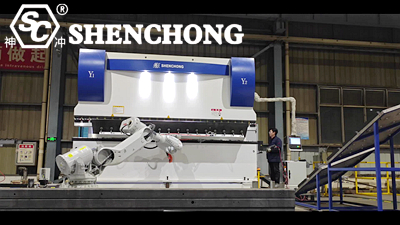

The SC 250T 5000 CNC Press Brake with Robot ABB-6700 300KG form an automated bending production unit. SC robot bending combines CNC press brake machines with industrial robots to form an automated bending system for efficient and precise bending of metal sheets.

This technology is widely used in the fields of automobile manufacturing, aerospace, home appliance manufacturing, architectural decoration, etc., and is an important part of intelligent manufacturing.

Achieve automated production, reduce manual intervention, and increase processing speed.

Particularly suitable for large-scale, multi-process bending processing.

The CNC system ensures precise control of bending angles and sizes.

The robot has high positioning accuracy to ensure the consistency of plate position.

The programmable robot adapts to a variety of plate shapes and sizes and supports small-batch and multi-variety production.

The mold replacement of the bending machine is convenient and suitable for complex bending processes.

Reduce manual handling and operation, and improve the safety of the working environment.

Particularly suitable for heavy plates and difficult bending processing.

Automated operation eliminates manual errors and ensures product quality consistency.

Long-term operation can significantly reduce labor costs and improve production efficiency.

If you have specific needs (such as plate specifications, production rhythm, bending complexity, etc.), I can recommend suitable equipment configurations and solutions for you.