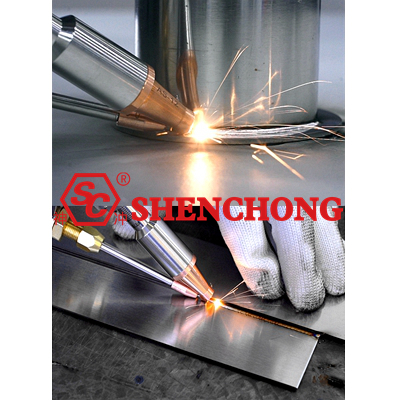

Laser welding is an efficient and precise welding method that utilizes a high-energy density laser beam as a heat source. Laser welding is one of the important aspects of the application of laser material processing technology.

In the 1970s, it was mainly used for welding thin-walled materials and low-speed welding. The welding process belongs to the type of heat conduction, that is, laser radiation heats the surface of the workpiece. Surface heat diffuses internally through heat transfer. By controlling parameters such as laser pulse width, energy, peak power, and repetition frequency, the workpiece is melted to form a specific molten pool.

Due to its unique advantages, it has been successfully applied in precision welding of micro and small parts. Laser welding is synonymous with high-precision welding. Laser technology is widely used in high-speed rail, aircraft, rockets, ships, precision engineering, automobiles, mobile phones, home appliances, and other products.

Laser welding belongs to melt welding, which uses a laser beam as the energy source to impact the welded joint.

The laser beam can be guided by a planar optical element (such as a mirror), and then projected onto the weld seam using a reflective focusing element or lens.

Laser welding is a non-contact welding process that does not require pressure, but requires the use of inert gas to prevent oxidation of the molten pool. Filler metal is occasionally used.

Laser welding can be combined with MIG welding to form laser MIG composite welding, achieving deep penetration welding.

Click here to know sheet metal laser cutting machine

Laser welding is an efficient and precise welding method that uses a high-energy density laser beam as the heat source, with advantages such as high efficiency, accuracy, simplicity, and ease of use. Nowadays, laser welding has been widely applied in various industries, such as electronic parts, automotive manufacturing, aerospace and other industrial manufacturing fields.

However, laser welding is not omnipotent, and sometimes processing errors may occur due to operational or parameter settings. Only by fully understanding these issues and learning how to avoid them can the value of laser welding be better realized.

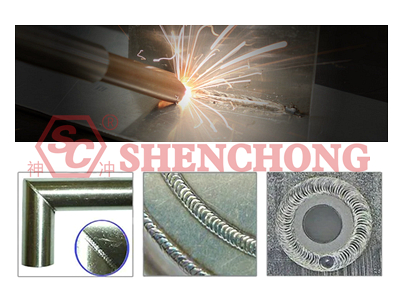

The spatter generated by laser welding seriously affects the surface quality of the weld seam, which can contaminate and damage the lens.

Generally, after laser welding is completed, many metal particles appear on the surface of the material or workpiece. There is metal attached to the surface of the material or workpiece.

Splash cause:

The surface of the processed material or workpiece is not cleaned thoroughly, with oil stains or pollutants, which may also be caused by the evaporation of the galvanized layer.

Solution:

- Before laser welding, pay attention to cleaning materials or workpieces.

- Splash is directly related to power density. Reducing welding energy appropriately can reduce splashing.

The cracks generated by continuous laser welding are mainly thermal cracks, such as crystal cracks, liquefaction cracks, etc.

The reason for the occurrence of cracks is mainly due to excessive shrinkage force before the weld is fully solidified.

Solution:

Measures such as wire filling and preheating can reduce or eliminate cracks.

Porosity on the surface of the weld seam is a common defect in laser welding.

Reasons for pore formation:

- Laser welding has a deep and narrow molten pool. The cooling speed is fast. The gas generated in the liquid molten pool cannot overflow in time, which can easily lead to the formation of pores.

- The surface of the weld seam is not cleaned thoroughly, or zinc vapor evaporates from the galvanized sheet.

Solution:

Clean the surface of the workpiece and weld seam before welding to improve the evaporation of zinc during heating. In addition, the direction of blowing can also affect the generation of pores.

Undercut refers to the occurrence of grooves due to poor bonding between the weld seam and the base material. Depth greater than 0.5mm. The total length is greater than 10% of the weld length or the length required by the acceptance criteria

Reason for undercut:

- Welding speed is too fast. The liquid metal in the weld seam will not redistribute on the back of the small holes, forming undercuts on both sides of the weld seam.

- Excessive clearance during joint assembly. The amount of molten metal in the joint filling is reduced, and it is also prone to undercutting.

- At the end of laser welding, if the energy drops too quickly, the small hole is prone to collapse and can also cause local undercutting.

Solution:

- Control the processing power and speed matching of the laser welding machine to avoid undercutting.

- The undercuts found during inspection can be polished, cleaned, and repaired to meet the requirements of the acceptance standards.

The weld seam is obviously overfilled, and the weld seam is too high during welding.

Reason for weld seam accumulation:

- The wire feeding speed is too fast.

- The welding speed is too slow during welding.

Solution:

- Increase welding speed.

- Reduce the wire feeding speed.

- Reduce laser power.

The weld metal will not solidify at the center of the joint structure.

Reason for deviation:

- Inaccurate positioning during laser welding.

- Inaccurate alignment with the welding wire during filling welding.

Solution:

- Adjusting the welding position

- Adjust the repair welding time and the position of welding wires, as well as the positions of lamps, welding wires, and welds.

Weld depression refers to the phenomenon of a depression on the surface of the weld metal.

Reason for depression:

During brazing, the center of the solder joint is poor. The center of the light spot is close to the lower plate and deviates from the center of the weld seam, resulting in partial melting of the base material.

Solution:

Adjust the filament matching.

Poor weld formation includes: poor weld ripple, uneven and irregular weld seam, uneven transition between weld seam and base metal, poor weld seam, and uneven weld seam.

The reasons for this situation include unstable wire feeding or discontinuous light during weld brazing.

Solution:

Adjust the stability of the device.

When the trajectory of the weld seam changes significantly, there is a tendency for weld beads or uneven formation at the corners.

Cause:

The weld trajectory changes greatly and the teaching is uneven.

Solution:

Weld under the optimal parameters, adjust the viewing angle, and make the corners coherent.

Surface slag inclusion refers to the fact that during the laser welding process, the visible surface slag mainly appears between layers.

Analysis of reasons for surface slag inclusion:

- When welding multiple layers and passes, the interlayer coating is not clean. Or the surface of the previous layer of welding seam is uneven or the surface of the welded part does not meet the requirements.

- Improper welding techniques such as low welding input energy and fast welding speed.

Solution:

- Choose a reasonable welding current and welding speed. When welding multiple layers and passes, the interlayer coating must be cleaned.

- Grind and remove weld seams with surface slag inclusions, and repair laser welding if necessary.