The concept of "Non-standard Automation" appears in response to the so-called "standard automation". Non standard automatic production line refers to the production composed of non-standard automatic equipment customized according to customer needs.

In the manufacturing industry, in order to cope with the production of large-scale stereotyped products, we design production lines, supplemented by standardized fixtures and tools, and formulated strict production processes (SOP), parts and materials lists (BOM) and quality control models (SIP). Thus, the whole process of the product line is effectively managed to achieve the effect of high production efficiency, low cost and good quality. This is the production model with "Standard Automation".

But in the face of rapid changes in market demand, its negative effects are very serious. When the products need to be updated, the whole production line will face the danger of overall scrapping.

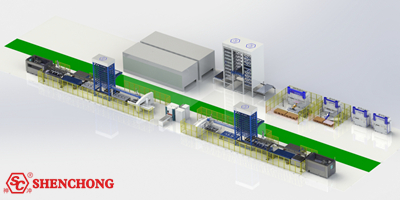

Non-standard automation equipment is user-customized, user-only, and non-market-circulated automation system integration equipment. It is assembled from unit equipment manufactured to uniform industry standards and specifications. It is the equipment developed, designed and manufactured according to the needs of customers. Different types of customers have different process requirements.

Non standard automation refers to non-standard automation equipment customized according to customer needs, which also belongs to the automation field. The function is an automatic mechanical equipment designed and customized according to the process requirements of enterprise users.

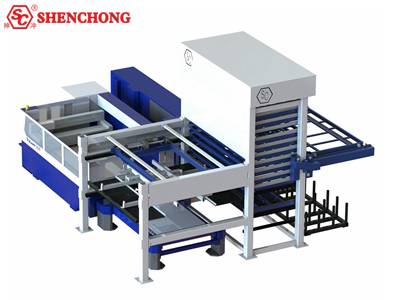

The core of non-standard automatic equipment is to design a complete set of mechanical motion structure and electrical control logic, realize the operation action of machine replacing human, and integrate multiple work units on a non-standard automatic equipment.

Realize automatic feeding, automatic assembly, automatic testing and detection of automatic equipment. And the data is fed back and saved in real time through the photosensitive elements of each key part, and the output efficiency, yield, energy consumption, etc. of the automation equipment can be seen through the visual interface.

Its operation is convenient and flexible. The function can be added according to the user's requirements, and there is much room for change. At present, it is commonly used in industries, electronics, medical, health, aerospace and other fields.

In order to improve efficiency and accuracy, some labor-intensive enterprises continue to improve and upgrade their internal hardware equipment, so that the assembly line operation method will gradually be replaced by automated robots. This shows that non-standard automation is a trend, and automation will continue to replace manual tasks to complete some simple and repetitive tasks.

Main industries where non-standard automation equipment is applied:

- Packaging, printing, textile and assembly industries;

- Manufacturing and installation of auto parts in the automobile manufacturing industry;

- Production, transportation and packaging in the food industry;

- Product transportation for electronic and electrical production lines;

- Warehousing facilities in the logistics industry also has a wide range of applications.

With the continuous increase of factory labor cost, more and more enterprises pay attention to the field of factory automation, which also brings great development opportunities to non-standard automation. With the shortage of human resources, non-standard automatic machinery will continue to expand and popularize in the future market.

In recent years, non-standard automation equipment has played an irreplaceable role in the fields of industry, electronics, medical treatment, hygiene and aerospace. Non-standard equipment, especially high-tech automatic equipment special machinery or production line, has made rapid development. What are the characteristics of non-standard automatic equipment?

The manufacturing of non-standard automation equipment is complex. There is no specific reference model for the production of equipment, and the requirements of different aspects such as functions, uses, and processes of customers should be considered.

Therefore, it is not as simple as the production of ordinary standard automation equipment. After all, the production and production of ordinary standard automation equipment has fixed and applicable regulations, and it can be produced according to the process.

At the same time, in the production, the blank precision of non-standard equipment is low and the machining allowance is large. Generally, it is processed with machine tools, and the production efficiency is low.

Non standard automatic equipment also belongs to the field of automation. Its function is to design and customize automatic mechanical equipment according to the process requirements of enterprise users, which often has strong professionalism.

Every time the equipment supplier designs and manufactures, it will be customized according to the preferences of different customers, product technology, quality requirements, on-site conditions and so on. At the same time, the production cost of non-standard equipment is high, and there are high requirements for technology and experience.

Because customers are from different industries and have different requirements for automation processes, non-standard automation equipment needs to be designed independently according to the specific place of use, industry characteristics and use.

There is no actual reference case for the design of non-standard automation equipment. The passing of each non-standard automation equipment scheme is the fruit of wisdom produced by a spark of thought.

Both non-standard and standard automation equipment can improve production efficiency while liberating more labor productivity, and constantly promote the transformation from "automation" to "intelligence" to adapt to today's rapidly changing market.