In automation equipment, we can devide truss manipulator into 3 parts: truss, manipulator and drive system.

We can simply regard the truss part as a beam. Because its structure is similar to the structural beam in mechanics.

From the mechanical point of view, we can make a transverse comparison between the machine tool truss and the simply supported beam. We can analyze the truss through the bending moment diagram of the simply supported beam to increase the force of the manipulator on the truss.

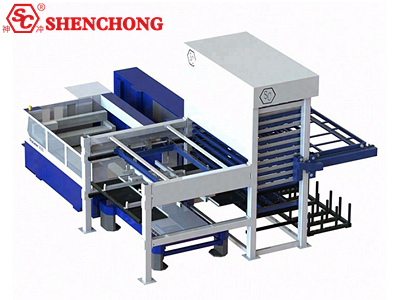

In machine tools, truss manipulators have high requirements. We require high efficiency and reliability of the manipulator.

For the column selection of the truss, it should make the truss support stable. At the same time, it also needs to save the overall space of the machine tool. For most column structures, we choose steel structure.

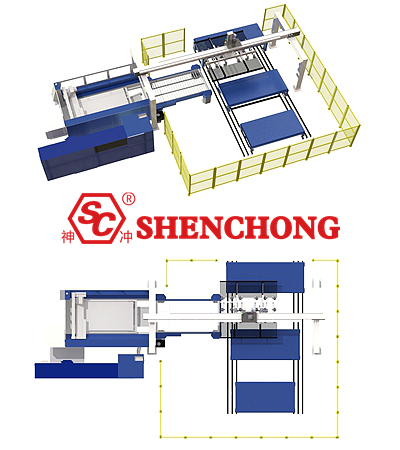

The truss manipulator is used for transportation. It makes the workpiece move between the loading and unloading track and the machine tool.

It takes the processed parts out of the machine tool, and then picks up the parts to be processed from the track and puts them on the machine tool.

- Claw open

- Grab

- Lifting

- Left and right movement, etc

There are many schemes and forms for the design of the gripper of the manipulator. We can choose different design methods according to different needs.

- Mechanical self-locking gripper:

This structure is very popular with customers. The structure of mechanical self-locking gripper is relatively simple. However, it has also made a complex design on the grab. In order to prevent falling off when clamping parts, a self-locking device is added.

- Linkage lever gripper:

We can associate its structure with its name. The connecting rod lever type gripper uses the mechanical connecting rod mechanism to clamp and release the gripper through the transmission of connecting rod and lever. However, this mechanism has a disadvantage that its clamping force is relatively large.

- Rack and pinion gripper:

This kind of organization has the best transmissibility. The action response speed is the fastest. It controls the gripper through the transmission between gears, which can achieve a breakthrough in speed.

For the arm design of the manipulator on the truss, we should consider the load of the manipulator. Realize fast movement in sports. However, they should also be able to bear it in institutions.

The manipulator on the machine tool truss generally moves in a straight line. So when considering the arm design, we generally choose the hydraulic direct drive manipulator.

In the selection of the hydraulic cylinder of the manipulator, we should make the diameter of the hydraulic cylinder larger. The overall strength of the truss manipulator arm will be higher.

Motion of truss manipulator:

The manipulator moves horizontally on the truss. After reaching the specified position, the manipulator moves downward. The gripper clamps the workpiece, drives the workpiece to rise, reversely moves, and places the part on the track. The gripper is released. During this period, there are several positions where the PLC controls the limiter, respectively when the descending and ascending of the manipulator stops.

When the manipulator clamps the part from the machine tool, the next workpiece moves to the undetermined area. After the robot finishes this action, it returns to the position of the part to be processed. The manipulator descends, clamps the part, and places the part in the machine tool. The manipulator returns to the initial position. PLC stops pulse output. Machine tool is processing the work pieces. The robot completes the movement. The truss manipulator does the above movements back and forth.

The driving mode of truss manipulator can be divided into rotary type and mobile type. This is distinguished by grasping.

This control method is to control the manipulator through the solenoid valve. It uses the airflow control valve to control the movement speed of the manipulator. The cost of this drive is relatively low.

In the design of truss manipulator, this driving mode is used most frequently. Because the machine tool needs electricity. This kind of drive system can achieve speed control only by using the motor.

The hydraulic drive mode is controlled by the hydraulic system. Its advantage is that it can realize continuous position control. At the same time, the transmission stiffness is also large. Hydraulic motor is generally selected as the power source for hydraulic drive.

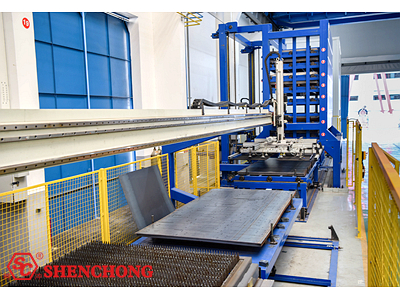

With the continuous development of the manufacturing industry, the labor cost is also in a rising trend. The popularity of machine tool automation has also increased.

But at the same time, we should also improve the supporting facilities of the machine tool, especially for the production of large quantities of parts. Manipulators are also used more and more widely.

For the development of modern industry, the development speed of manipulator is not very fast. It is very convenient to use PLC control for manipulator control. The development of the manipulator should be continuously developed. Automation equipment manufacturers need to objectively analyze the actual situation to design and organically combine multiple elements.

Automation can help enterprises realize digital transformation. At present, the traditional manufacturing and machinery industries are facing a wave of disruptive transformation.

We have to deal with various challenges. We should not only provide support for employees and partners, but also develop new customers. We should also provide innovative products and services at a faster speed. It is imperative to become a subverter of the industry.

We are devoted to improving the efficiency of manufacturing and its upstream & downstream processes. Through further development and research of automation technology, Shenchong machines will be more efficient, accurate and future-proof. Our goal is to make automation equipment available to everyone. Promote production and lead the future into Industry 4.0!