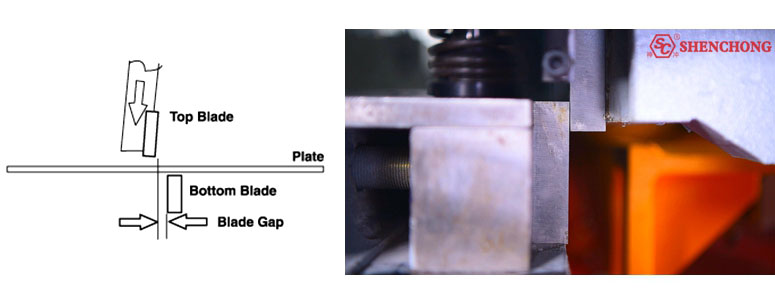

The shearing machine blade gap refers to the distance between the upper and lower blades on the shearing machine. This gap has an important impact on the shearing quality. Too large a gap will cause the shearing surface to be uneven and have too many burrs. Too small a gap will increase the shearing resistance, causing the blade to wear faster or be damaged. Reasonable blade gap can improve the shearing effect and extend the service life of the blade.

Shearing Machines are powerful devices used to cut sheets of metal. The process is simple, two knives are positioned at an angle relative to one another, the lower knife is stationary and rigidly attached to the table, the upper knife is attached to a ram assembly and moves. The two blades are separated by a clearance measured in thousands of an inch.

Blade clearance is the distance between the upper and lower blade of the shear as they pass each other during the shearing process. It is defined as the separation between the blades, measured at the point where the cutting action takes place and perpendicular to the direction of blade movement.

The clearance of the blades is the key aspect to producing a quality cut and to keeping the shearing machine in working order.

Improper blade clearance will affect the machine’s power consumption and the finish of the cut. The quality of cut and edge quality will be reduced if the cutting clearance is too large. When the clearance is larger than the proper alignment, the material is drawn between the two blades. This improper alignment will lead to undesirable results and will not reflect the capability of the machine.

For the plate shears to be as efficient as possible, the blade clearance must remain at the optimal adjustment. This step is the biggest key factor to providing a quality cut. Eliminating burr and turn over is accomplished by keeping a proper adjustment of the blade gap of the shearing machine. Adjusting the gap to adapt to the cutting of various places produces the best results. The blade clearance is not standardized across all cuts and must be readjusted to accommodate for new cuts needed.

The adjustment of the shearing machine blade gap needs to consider many factors, including the thickness of the sheared material, the material and the shearing requirements. Under normal circumstances, the adjustment range of the blade gap is 5%-10% of the thickness of the sheared material.

Maintaining proper blade clearance is crucial to the operation and performance of a shearing machine. Without the standard of operation being met, the machine will not produce the high-quality results it is capable of. To ensure that the shearing machine blade clearance is at the optimal point for peak production, several steps must be met.

The specific adjustment method and steps are as follows:

When adjusting the shearing machine blade gap, it is recommended to refer to the shearing machine's instruction manual or consult a professional technician to ensure correct adjustment and safe operation.

Shutdown and power off: Make sure the shearing machine is in a completely stopped state and cut off the power supply to ensure safety. First, turn the key switch to the adjustment position. Make sure it is in the proper place.

Loosen the locking device: Find and loosen the locking device that controls the blade gap.

Adjust the gap: Adjust the distance between the upper and lower blades according to the thickness of the sheared material. This can be achieved by adjusting bolts, handwheels or other adjustment devices.

Check the gap: Check the adjusted gap with a feeler gauge or professional measuring tool to ensure that it is within a reasonable range. Double-check the clearance to ensure that it is correct.

Locking device: Re-lock the device that controls the gap to ensure that the blade will not loosen during use.

Trial cutting and inspection: Perform a trial cut to check the cutting effect and make fine adjustments if necessary.

Once you have completed the previous steps, the shearing blade machine should be set optimally to deliver the best quality cuts. Turn the key switch to the cutting position to begin the plate shearing process.

The most important component of the shearing process is the clearance between the blades. Without proper clearance, the quality of the cut is affected. The machine can be affected by this as well. Negative results lead to improper use of the machine and extra wear and tear that is unnecessary.

The blade gap of the shearing machine is of great significance to the quality of the shearing process and the service life of the equipment. The following is the importance of blade gap:

Shearing surface finish: Reasonable blade gap can ensure smooth and flat shearing surface, reduce burrs and irregular edges.

Reduce deformation: Appropriate gap can reduce deformation and tearing of materials, and improve the neatness and precision of shearing.

Reduce wear: Too large a gap will increase the impact force during shearing, making the blade prone to cracks and chipping. Too small a gap will increase the friction of the blade, causing the blade to wear more.

Extend service life: Reasonable blade gap can effectively reduce blade wear and damage, extend the service life of the blade, and reduce maintenance costs.

Prevent equipment damage: Unreasonable blade gap may increase the load of the equipment, causing damage or failure of mechanical parts.

Ensure operational safety: Too small a gap may cause the blade to jam, or even cause mechanical failure and operational accidents.

Shearing machine blade clearance is an issue of safety and production. Safety becomes a major concern when a machine, or any product, is used improperly. When a machine is not kept at the expected operating standard, malfunction and break down of the machine is more likely. These safety concerns extend beyond the machine itself. The user is more prone to injury when a machine is not being operated properly.

Improve production efficiency: Appropriate blade gap can increase shearing speed and efficiency, reduce downtime and adjustment time.

Reducing costs: By reducing blade wear and maintenance frequency, production and maintenance costs can be reduced.

The steps involved in adjusting the clearance must be adhered to for each different angle or type of cut needed. If the blades are not readjusted for new cuts, then the intended result will not be met. Blades that are not readjusted will continue to perform the previously set measure of cut.

The safety of the user is a primary concern when employing the use of any heavy machinery. If safety conditions are not met, and proper procedures are not followed, the safety of the user is at risk. It is important to be thorough in adjustments and measurements. The quality of the machine and the blades is at risk when intended procedures are skipped or ignored. The CNC plate shearing machine blade clearance can and should be adjusted incrementally for each different desired cut.

Therefore, when using the shearing machine, it is very important to adjust and maintain the appropriate blade gap, which not only affects the shearing quality and efficiency, but is also directly related to the safety and service life of the equipment.

Click here to know:

How To Select Hydraulic Shear Blades

How to Remove and Install Plate Shear Blade