Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. Shearing is a process that separates metal sheets into the required size and shape. During the shearing process, the force exerted by the tool on the metal sheet separates the material along the cutting line. The shear cutting force depends on several factors: material strength, material thickness, shear tool sharpness, shearing speed, and tool gap.

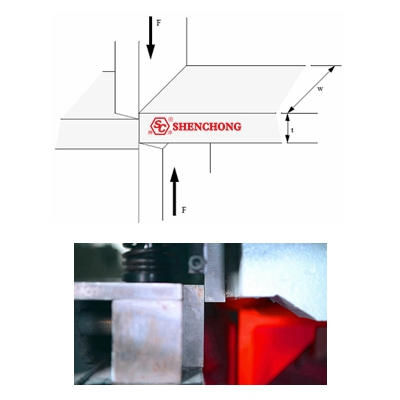

"Shear cutting force" refers to the relative dislocation and deformation of the cross-section of the material along the direction of action of the external force under the action of a pair of lateral external forces (that is, the force perpendicular to the action surface) that are very close to each other and have the same magnitude and opposite directions. The force that can cause shear deformation of a material is called shear force or shear force. The section where shear deformation occurs is called the shear plane. The key to judging whether it is a "shear force" is whether the cross-section of the material is relatively dislocated.

The cutting process is the process of separating a sheet of metal by applying enough force to cause the material to fail. The most common cutting process is performed by applying a shearing force, so it is sometimes referred to as a shearing process. When enough shear force is applied, the shear stress in the material will exceed the ultimate shear strength and the material will fail and separate at the cut location. The shearing process is carried out on shears, commonly called square shears or power shears, which can be operated manually or hydraulically, pneumatically or electrically.

A typical shearing machine includes a table with support arms to hold the sheet, stops or guides for holding the sheet, upper and lower straight edge blades, and a measuring device for precise positioning of the sheet. Place the sheet between the upper and lower blades and press them together on the sheet, cutting the material. In most devices, the lower blade remains stationary while the upper blade is forced down. The upper blade is slightly offset from the lower blade, approximately 5-10% of the sheet thickness. In addition, the upper blade is usually angled so that the cut is made from one end to the other, reducing the force required. The blades used in these machines often have square edges rather than cutting edges, and are available in different materials such as low-alloy and high-carbon steels.

WUXI SHENCHONG shearing machine is hydraulic guillotine shearing machine and can work with high precision and high efficiency, it can effectively improve the production efficiency and product quality of the factory.

- Plate Tensile Strength Limit: Tensile strength refers to the maximum stress that a material can withstand before breaking, so, the greater the tensile strength of the sheet, the greater the shear cutting force it needs.

- Plate thickness: Under the premise of the same tensile strength, the greater the thickness of the sheet, the greater the shear cutting force will be.

- Shearing angle: The shearing angle of the shearing machine refers to the angle between the upper and lower blades of the shearing machine, which is generally controlled at 0.5 degrees to 2 degrees. Not all shears can be adjusted. Shenchong specializes in hydraulic guillotine shearing machine, which can adjust the shearing angle manually or electrically.

Generally speaking, the larger the shear angle, the larger the shear cutting force. But it does not mean that the bigger the angle, the better. It needs to be adjusted to the most suitable angle according to the thickness and material of the plate, and the precision of the cutting plate is the highest.

Material strength: The higher the shear strength of the material, the greater the shear force required.

Material thickness: The thicker the plate, the greater the shear force required.

Sharpness of the shearing blade: The sharper the tool, the lower the shear force.

Shearing speed: The faster the shearing speed, the greater the instantaneous shear force required.

Shearing blade gap: The smaller the gap between the tools, the better the shearing effect, but the required shear force may increase.

Click here to know more about: Shearing Machine Blade Clearance

F=τ⋅A

Among them:

- F is the shear force

- τ is the shear strength of the material

- A is the shear area (usually the plate thickness multiplied by the shear length)

By understanding and calculating the shearing force, you can choose the appropriate shearing equipment and process parameters to ensure a smooth shearing process and guarantee the quality of the final product.

The shearing force of a guillotine sheadr machine refers to the force that the machine needs to apply when shearing metal sheets. A guillotine plate shearing machine is a device used to shear metal sheets, which cuts the sheet through the relative movement of the upper and lower blades.

The shear cutting force calculation of inclined blade shear with blade support in straight motion mainly use the Norshari Formula by the former Soviet scholar:

σb – Plate Tensile Strength Limit(N/mm);

δx—Plate Elongation Ratio;

h—Plate Thickness(mm);

α— Cutting Angle(°);

X、Y、Z – Respectively refer to bending force coefficient, the relative value of the blade lateral clearance, pressing material coefficient.

Obviously, the shear relief angle change during shearing is not considered in the formula, and the shear gap is also considered as a one-time value. Due to the coexistence of shearing action and tensile force in the shearing process, the larger the shearing gap, the larger the proportion of the tensile force, and the worse the corresponding shearing quality.

When the shear gap is larger than the empirical value, it will inevitably cause a change in the shear force. According to formula (1), the increase of the shear gap will lead to an increase in the relative value of the shear lateral gap, and finally increase the shear force caused by the shearing process. required force. Therefore, when using the above formula to calculate the cutting force of the rotary shear, a larger relative value of the shear blade side clearance and the blade passivation coefficient should be selected to compensate for the above factors.

In short, the calculation of the shear cutting force of the shearing machine is a calculation formula within the technical field. Most of them are calculated by ordinary Q235 steel plate. When Q345 is calculated in millimeters, it is calculated by 1.4 times, and 304 stainless steel is calculated by 2 times.

For example: Q235 plate length 4000mm, thickness 6mm, the shear cutting force is 4000*6*23.5=564000N=56.4T. If for Q345 plate, the shear cutting force is 56.4*1.4=78.96T; for stainless steel plate, the shear cutting force is 56.4*2=112.8T.

When designing and selecting a metal sheet shearing machine, the shear force needs to be considered to ensure that the equipment can operate under safe and efficient conditions. By correctly calculating the shear force, the appropriate shearing machine model and specifications can be selected to ensure the smooth progress of the shearing process and the quality of the final product.

Click here to know:

Shear Machine Advantages & Price Analysis