The client of this project is an intelligent machinery manufacturing company. The customer's requirement is to bend a piece of stainless steel plate 5.2m long, 3m wide and 200kg in weight. A total of six bends are required.

1. Customer's production requirements and related problems

If the operation is completely manual, 8 skilled operators and 2 cranes are required for auxiliary hoisting. Only 8 plates can be processed in one day. It is also very easy to drop the sheet. Therefore, the customer chose to use robot bending instead of manual operation.

2. Introduction: Robot Bending Cell and Processing Flow

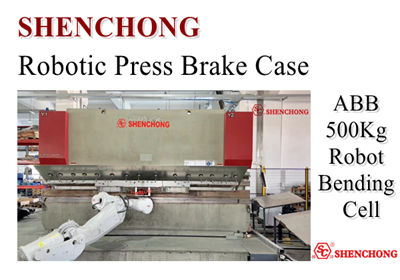

After a month of adjustment, the ABB robotic press brake bending cell, in the charge of Wuxi Shenchong Forging Machine Co., Ltd., has been put into production.

1) Composition of Robot Bending Unit

The whole bending unit includes:

- 400 ton 6m CNC Press Brake Machine

- 500kg robot

- Feeding table

- Centering platform

- Turning table

- Finished product transportation line

2) Processing Flow

The whole bending process takes 8 minutes:

- 30 seconds for loading

- 30 seconds for centering

- 5 minutes and 50 seconds for 6 step bends

- 50 seconds for turning

- 20 seconds for storage

Click here to know more about the project:

ABB 500Kg Robot Bending Cell Put Into Operation

3. Advantages of Robotic Bending Unit Process

The previous manual bending speed is one hour to complete a plate. In comparison, the efficiency has been improved significantly.

In addition, only one worker is required to operate the whole bending production cell, which greatly reduces the company's labor cost.

Safety guardrails are installed outside the whole robot bending cell. Once a worker enters the operation area by mistake, the robot will stop working. During the whole bending process, the operator only needs to stand outside the guardrail and complete the control of the whole bending unit through the teaching device, thus ensuring the safety of personnel in the production process.

Automatic production is the general trend of manufacturing industry. Using robots to replace manpower for sheet metal processing greatly improves efficiency, ensures personnel safety, and saves manpower and material resources in the long run.