Power density is one of the most critical parameters in laser processing. Using a higher power density, the surface layer can be heated to the boiling point within a microsecond time range, resulting in a large amount of vaporization.

High power density is beneficial for material removal processing, such as drilling, cutting, and engraving. For lower power densities, it takes several milliseconds for the surface temperature to reach the boiling point. Before the surface layer vaporizes, the bottom layer reaches the melting point, which facilitates the formation of good fusion welding.

Therefore, in conductive metal sheet laser welding, the power density ranges from 104 to 106W/cm ².

The waveform of laser pulses is an important issue in laser welding, especially for thin plate welding.

When a high intensity laser beam is emitted onto the material surface, 60~98% of the laser energy will be reflected off the metal surface and lost, and the reflectivity will vary with the surface temperature. During the action of a laser pulse, there is a significant change in the reflectivity of the metal.

Pulse width is not only an important parameter that distinguishes material removal and material melting, but also a key parameter that determines the cost and volume of processing equipment.

Laser welding usually requires a certain degree of defocus. Because the power density at the center of the laser spot is too high, it is easy to evaporate into holes. The power density distribution is relatively uniform on each plane away from the laser focus.

There are two defocusing methods: positive defocusing and negative defocusing.

The focal plane located above the workpiece indicates positive defocusing, while the opposite indicates negative defocusing. According to the theory of geometric optics, when the work done by positive and negative ions is equal, the power density on the corresponding plane is approximately the same, but in reality, the shape of the obtained molten pool is different.

When negative defocusing occurs, greater melting depth can be obtained, which is related to the formation process of the molten pool. Experiments have shown that laser heating of 50-200us materials begins to melt, forming liquid phase metals and causing partial vaporization, forming market pressure steam, and spraying at extremely high speeds, emitting dazzling white light. At the same time, the high concentration of vapor causes the liquid phase metal to move to the edge of the molten pool, forming a depression at the center of the molten pool.

When negative defocusing occurs, the internal power density of the material is higher than the surface, leading to stronger melting and vaporization, allowing light energy to be transmitted deeper into the material. So in practical applications, negative defocusing is used when a larger melting depth is required; When welding thin materials, positive defocusing should be used.

Click here: 10 Laser Welding Problems and Solutions

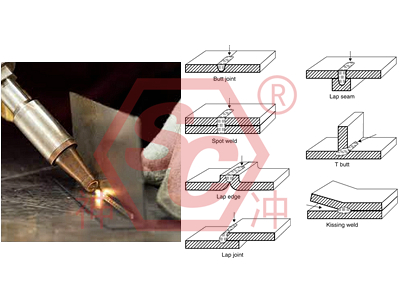

It includes four process methods: butt welding, end welding, center penetration fusion welding, and center hole fusion welding.

Including wire-to-wire butt welding, cross welding, parallel lap welding, and T-shaped welding.

Laser welding can be used to successfully connect metal wires to block components, and the block components can be of any size. Attention should be paid to the geometric dimensions of the filament components during welding.

Welding different types of metals requires solving weldability and weldability parameter ranges. Laser welding between different materials is only possible with certain material combinations.

Some components should not be connected by laser welding, but lasers can be used as heat sources to perform soft soldering and hard soldering, which also have the advantages of laser welding.

There are many methods of soldering. Among them, laser soldering is mainly used for soldering printed circuit boards, and is especially suitable for chip component assembly technology.

- Due to local heating, the components are less prone to thermal damage. The heat affected zone is small, so soft soldering can be carried out near the thermosensitive element.

- Using non-contact heating to melt the bandwidth, without the need for any auxiliary tools, it can be processed after equipping double-sided components on double-sided printed circuit boards.

- Good stability during repeated operations. The flux has little pollution to welding tools, and the laser irradiation time and output power are easy to control, resulting in a high yield of laser brazing.

- Laser beams are easy to achieve beam splitting, and optical components such as half lenses, reflectors, prisms, and scanning mirrors can be used for temporal and spatial segmentation, enabling simultaneous symmetric welding of multiple points.

- Laser brazing often uses a laser with a wavelength of 1.06um as the heat source, which can be transmitted through optical fibers. Therefore, it can be processed in areas that are not easily welded by conventional methods, with good flexibility.

- Good focus, easy to achieve automation of multi station devices.

The metallurgical process of laser deep penetration welding is very similar to that of electron beam welding, where the energy conversion mechanism is achieved through a "small hole" structure.

Under the irradiation of a sufficiently high power density beam, the material evaporates and forms small pores. This small hole filled with steam is like a blackbody, almost completely absorbing the energy of incident light, and the equilibrium temperature inside the hole cavity reaches around 25000 degrees. Heat is transferred from the outer wall of this high-temperature cavity, causing the metal surrounding the cavity to melt.

The small hole is filled with high-temperature steam generated by the continuous evaporation of the wall material under the irradiation of a beam of light. The four walls of the small hole are surrounded by molten metal, and the liquid metal is surrounded by solid material. The liquid flow outside the hole wall and the surface tension of the wall layer are in dynamic equilibrium with the steam pressure continuously generated in the hole cavity.

The beam continuously enters the small hole, and the material outside the hole continuously flows. As the beam moves, the small hole remains in a stable state of flow. That is to say, the small hole and the molten metal surrounding the hole wall move forward with the forward speed of the leading beam, and the molten metal fills the gaps left after the small hole is removed and condenses accordingly, forming the weld seam.

The factors that affect laser deep penetration welding include: laser power, laser beam diameter, material absorption rate, welding speed, shielding gas, lens focal length, focal point position, laser beam position, laser power gradually increasing and decreasing control at the starting and ending points of welding.

- High aspect ratio. Because molten metal forms around a cylindrical high-temperature steam chamber and extends towards the workpiece, the weld seam becomes deep and narrow.

- Minimum heat input. Due to the high temperature of the source cavity, the melting process occurs very quickly, the input heat of the workpiece is extremely low, and the thermal deformation and heat affected zone are very small.

- High density. Because the small holes filled with high-temperature steam are conducive to the stirring of the fusion pool and the escape of gas, resulting in the formation of non porous penetration welding. The high cooling rate after welding can easily refine the microstructure of the weld seam.

- Strong weld seam.

- Precise control.

- Non contact, atmospheric welding process.

- Because the focused laser beam has a much higher power density than conventional methods, it results in fast welding speed, smaller heat-affected zone and smaller deformation, and can also weld difficult-to-weld materials such as titanium and quartz.

- Because the beam is easy to transmit and control, and there is no need to frequently replace the welding torch and nozzle, which significantly reduces the downtime auxiliary time, the load factor and production efficiency are both high.

- Due to the purification effect and high cooling rate, the weld is strong and the overall performance is high.

- Due to low equilibrium heat input and high processing accuracy, reprocessing costs can be reduced. In addition, the rotation cost of laser welding is also relatively low, which can reduce production costs.

- It is easy to realize automation and can effectively control the beam intensity and fine positioning.

Laser deep penetration welding usually uses continuous wave CO2 laser. This type of laser can maintain a high enough output power to produce a "pinhole" effect, penetrating the entire workpiece cross-section and forming a strong welded joint.

As far as the laser itself is concerned, it is just a device that can produce a well-directed parallel beam that can be used as a heat source. If it is guided and effectively processed and then shot towards the workpiece, its input power will have strong compatibility, making it better adapted to the automation process.

In order to effectively implement welding, the laser and other necessary optical, mechanical and control components together form a large welding system. This system includes the laser, beam delivery components, workpiece loading and unloading and moving devices, and control devices

This system can simply allow the operator to manually transport and fix workpieces, or it can include automatic loading, unloading, fixation, welding, and inspection of workpieces. The overall requirement for the design and implementation of this system is to achieve satisfactory welding quality and high production efficiency.

In general, the metal sheet laser welding effect of carbon steel is good, and its welding quality depends on the impurity content.

Just like other welding processes, sulfur and phosphorus are sensitive factors that cause welding cracks. In order to obtain satisfactory welding quality, preheating is required when the carbon content exceeds 0.25%.

When steels with different carbon contents are welded to each other, the welding torch can be slightly biased toward the low-carbon material to ensure joint quality.

Low carbon boiling steel is not suitable for laser welding due to its high sulfur and phosphorus content. Low carbon killed steel has good welding effects due to its low impurity content.

Both medium and high carbon steels and ordinary alloy steels can be well laser welded, but preheating and post-welding treatment are required to relieve stress and avoid crack formation.

In general, stainless steel metal sheet laser welding is easier to obtain high-quality joints than conventional welding. Due to the small heat-affected zone at high welding speeds, sensitization is not a significant problem. Compared with carbon steel, the low thermal conductivity of stainless steel makes it easier to obtain deep-penetration narrow welds.

The extremely high cooling rate and small heat-affected zone of laser welding create favorable conditions for the compatibility of materials with different structures after melting many different metals.

It has been proven that the following metals can be successfully welded by laser deep penetration: stainless steel ~ low carbon steel, 416 stainless steel ~ 310 stainless steel, 347 stainless steel ~ HASTALLY nickel alloy, nickel electrode ~ cold forged steel, bimetallic strips with different nickel contents.