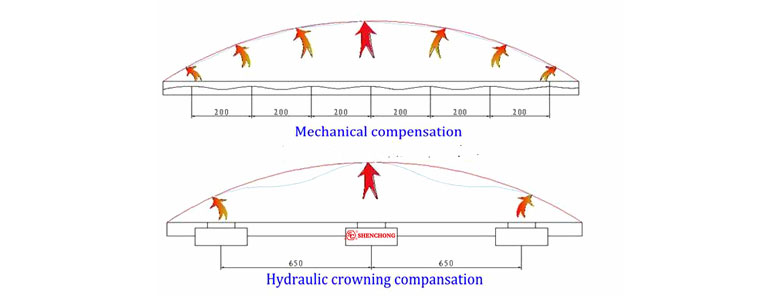

In the bending process, when the CNC press brake machines make force on the plate, the plate will also react force on the machine. This reaction force will cause the machine to deform, which will affect the bending accuracy. Therefore, in order to improve the bending accuracy, mechanical compensation and hydraulic compensation, two press brake crowning compensation are widely used in the plate bending process.

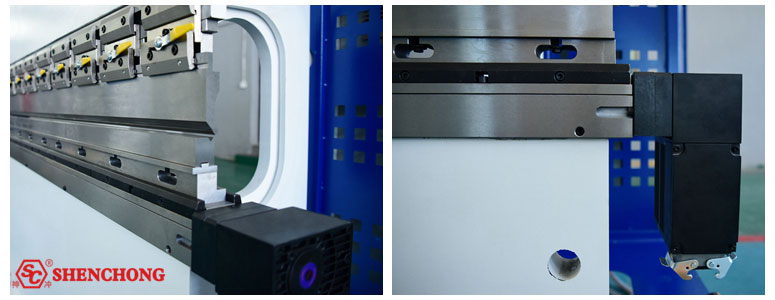

The protruding wedges are composed of a group of protruding oblique wedges with inclined surfaces. Each protruding wedges is designed according to the deflection curve of the sliding block and the working table by the finite element analysis.

The CNC controller system calculates the required compensation amount according to the load force. This force will cause the deflection and deformation of the slider and the table vertical plate. And automatically controls the relative movement of the convex wedge, thereby effectively compensate the deflection deformation produced by the sliding block and the vertical plate of the worktable, and can obtain the ideal bending workpiece.

The curve of the actual deflection coincides with the same, so that the gap between the upper and lower tools is consistent during bending, and the angle of the bending workpiece in the length direction is consistent.

Mechanical crowning can obtain accurate deflection compensation over the full length of the worktable. Mechanical deflection compensation has long-lasting stability, reduces the maintenance frequency of hydraulic compensation (such as oil leakage), and is maintenance-free during the life of the machine tool.

Mechanical deflection compensation because there are more compensation points, so that the bending machine can achieve linear compensation when bending the workpiece while working, and can improve the bending effect of the workpiece. Mechanical compensation is driven by a motor as a CNC controlled axis, which realizes CNC control and makes the compensation more accurate.

The work table automatic hydraulic deflection compensation is composed of a set of oil cylinders installed in the lower workbench. The position and size of each compensation cylinder are designed according to the deflection compensation curve of the slider and the finite element analysis of the workbench.

The hydraulic crowning is to realize the convex compensation of the neutral version through the relative displacement between the front, middle and rear three vertical plates. The principle is to realize the protrusion through the elastic deformation of the steel plate itself, so the compensation amount can be adjusted within the elastic range of the worktable.

Because the two press brake crowning compensation methods are different on operators requirements and product accuracy, so selecting correct bending compensation is very important.

Hydraulic compensation means that several small oil cylinders are placed under the workbench. When the machine deforms, additional force is applied through these small oil cylinders to compensate, thereby reducing the influence of machine deformation on the folded plate.

The CNC controlled hydraulic compensation: we set the bending parameters in the cnc controller, like plate thickness, plate length, material. CNC controller will calculate the required compensation value automatically, then transmit the command to the compensation amplifier. The compensation amplifier sent the signals to hydraulic compensation proportional valve, which will control the small oil cylinder under the workbench to bulge and reduce the deflection deformation of the plate.

However, the compensation value of hydraulic crowning is affected by many factors, such as whether the hydraulic oil leaks, loose joints, etc., which will affect the amount of hydraulic compensation each time, resulting in inconsistencies and differences in the processing of plates each time.

The hydraulic crowning system is more complicated, and problems such as oil leakage and loose sealing rings may occur. The advantage of hydraulic crowning is: as the use time increases, the machine will not have wear problems, while mechanical compensation will have wear problems.

Compared with mechanical compensation, the machine with hydraulic compensation is simple to operate, so it can help bending with higher precision. Moreover, the machine has higher durability.

Hydraulic crowning compensation adopts small oil cylinders to compensate the worktable, while mechanical compensation uses a wedge block to compensate the worktable. The oblique wedge can be divided into single oblique wedge and multiple sets of oblique wedges.

The multiple sets of oblique wedges mechanical compensation has more compensation points than the hydraulic crowning compensation, which only has 3 compensation points for ordinary hydraulic crowning, there is no compensation blind zone, the precision of the folded workpiece is higher, and the difference between the processing plate is small each time, which is suitable for mass production.

Compared with the hydraulic crowning compensation system, the mechanical compensation system is simpler, will not cause oil leakage and other conditions, has a low failure rate and is environmentally friendly.

However, after long time using, the oblique wedge of mechanical crowning will wear out, which will affect the compensation effect. Mechanical compensation has higher requirements for operation. If the workpiece need be bent multiple steps, workers need to make real-time adjustments.

If the workpiece only need to be bent single step, and our workers have high skill. We can select mechanical compensation from the perspective of the workpiece accuracy. In actual production, we have to consider the ability of workers, the cost of high skill workers and etc.

In summary, both hydraulic compensation and mechanical crowning compensation have their own advantages. We can consider configuring the worktable compensation of our press brake machine based on the above aspects.