With the advancement of the times and the increase of labor costs, the efficiency has not improved much compared to before. Under such circumstances, in order to improve efficiency, customers will also ask about the method of loading and unloading when purchasing laser cutting machines, and some factories currently have had laser cutting machines will also consider automatic loading and unloading systems.

And now, let's explain the features and types of the laser cutting loading system briefly.

- From production scheduling, type setting programming to raw material storage, raw material loading, cutting, transfer of workpieces and waste after cutting, automatic and planned processing.

- Realize automatic loading and unloading transfer from plate thickness 110mm. The processed plates can be stored centrally.

- Equipped with an automatic loading device/unloading device; use a vacuum suction cup to move in materials, and use a fork to move out the cut plates, which can realize the docking with the production system, execute the production plan, and realize production management.

- Equipped with high and low double-layer sorting tables to achieve a stacked weight of 5t after cutting and blanking; the sorting table can be moved to the sorting area to facilitate manual centralized sorting. Equipped with 2 or more sorting tables to avoid centralized output material, resulting in a long waiting time.

- Ensure that the start-up ratio of the laser cutting machine is greater than 85%; the cutting time in one day is greater than 20h.

- Equipped with safety fence and various safety interlock switches to ensure the safe use of the machine. When a laser cutting machine in the entire system fails, the automatic loading and unloading system can perform loading and unloading operations for a laser cutting machine that is not faulty, and ensures the safety of maintenance personnel in the manual work area.

- After the system is started, the laser cutting machine can realize a series of cyclic actions such as table exchange, edge finding, cutting, etc., and realize the automatic operation of the machine tool. The operation mode can be selected as automatic mode, and the cutting cycle is carried out automatically, or manual mode, and only one cutting cycle is completed.

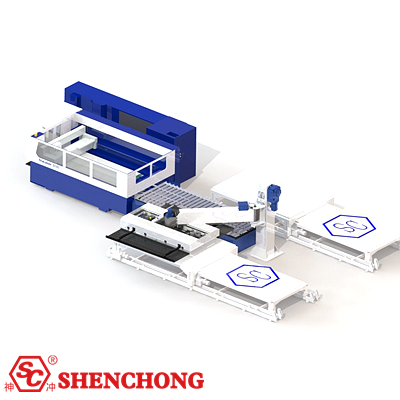

- Cantilever type laser cutting loading and unloading system (limited space): Its main advantage is that it is convenient to transport, more flexible, and can be installed at any point as your need.

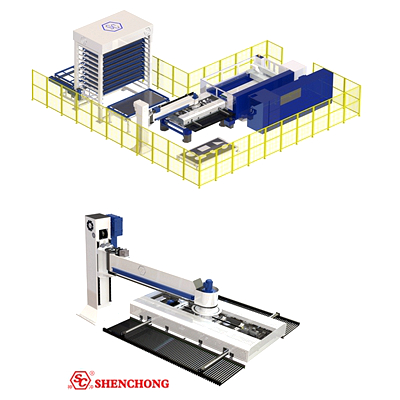

- Truss type laser cutting loading and unloading system (unlimited space): Its main advantages are higher visibility, faster moving speed in a straight line distance, and will not be limited by the weight of the plate.

Cantilever type loading & unloading system and truss type loading & unloading system with the mobile exchange trolley can also be added during the unloading process. After the laser machine cuts the plate, all the finished materials are unloaded to the trolley by holding the fork, and the trolley moves to a safe position for manual sorting. The trolley travels to the unloading station, so that repetitive work is performed.

Wuxi Shenchong always make corresponding laser cutting machine loading and unloading solutions according to customers' specific needs. So, if there is a need for laser cutting loading system, please feel free to contact us for specific proposal as a reference.