Intelligent manufacturing is a human-machine integrated intelligent system composed of intelligent robots and human experts. It can carry out intelligent activities in the manufacturing process, such as analysis, reasoning, judgment, conception and decision-making.

To amplify, extend and partially replace the mental work of human experts in the manufacturing process through the cooperative work of humans and intelligent robots.

It updates and expands the concept of manufacturing automation to flexibility, intelligence and high integration. Intelligent manufacturing includes intelligent manufacturing system (IMS) and intelligent manufacturing technology (IMT).

- Self organizing ability

- Self discipline ability

- Intelligent integration of the whole manufacturing system

- Self learning and self maintenance ability

- Virtual reality

- Man machine integrated intelligent system

- Artificial intelligence technology

- Concurrent engineering technology

- Virtual manufacturing technology

- Information network technology

In a broad sense, computer integrated manufacturing system and flexible manufacturing can be regarded as examples of intelligent manufacturing applications.

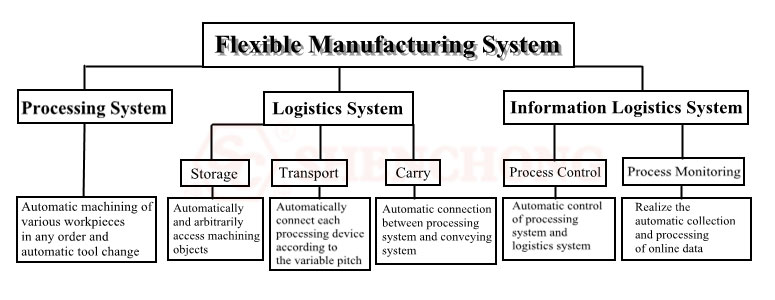

- Flexible manufacturing system (FMS)

- Several CNC machining systems

- Material handling system

- Loading and unloading system (rotary pallet and industrial robot)

- Three dimensional warehouse (intelligent storage system)

- Optimize dispatching management (information control)

Integrate the above to form a relatively complete system of processing, loading and unloading, transportation and management. It has the functions of monitoring, diagnosis, repair and automatic conversion of processed product varieties.

FMS composition diagram

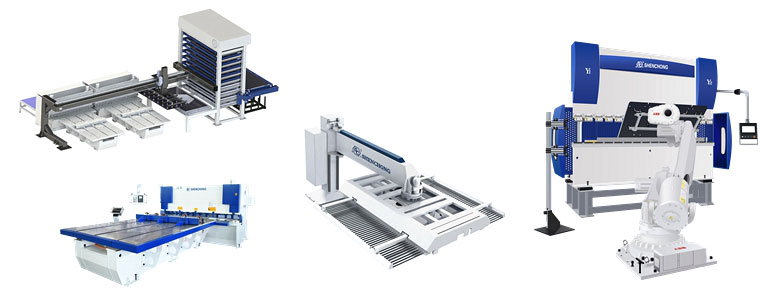

High-precision CNC machine tool

Automated manufacturing system is very important in flexible manufacturing.

Automatic guided car AGV

Robot arm

Automated three-dimensional storage system

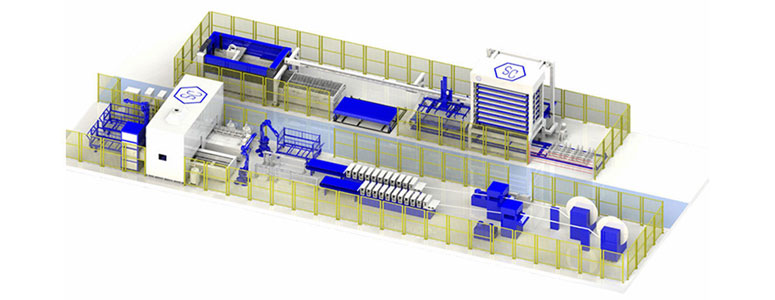

Integrating various production technologies into one system forms an automatic production system. This production system or production line can improve quality, shorten cycle time, save manufacturing cost and manpower, and increase safety.

Intelligent manufacturing technology can be applied to process monitoring and intelligent fault diagnosis of flexible manufacturing system.

Intelligent process monitoring and intelligent fault diagnosis:

- Tool working status detection and early warning

- Machining workpiece quality detection and error compensation

- Processing equipment turntable monitoring and fault diagnosis

- Machining process status monitoring and fault diagnosis

Advantages of flexible manufacturing system

- Decision expert system

It can make the flexible manufacturing system in the design meet the expected performance indexes, and prevent the scale design of the system from being too high or too low, so as to avoid wasting funds and leading to the failure of system planning.

- Intelligent equipment

It makes the task complete more quickly, accurately, efficiently and saves manpower.

- Intelligent production scheduling

It can quickly and funny complete its production scheduling task by allocating the task of each work piece flowing between various devices.

- Intelligent process monitoring and intelligent fault diagnosis

It can timely find the faults of equipment and processing process in the production process, and make rapid compensation adjustment. Improve production efficiency and save manpower.

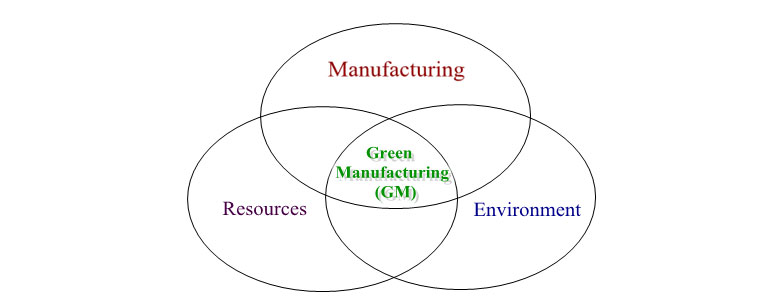

Green Manufacturing (GM) is a modern manufacturing mode that comprehensively considers environmental impact and resource consumption.

Its goal is to minimize the negative impact on the environment and maximize the utilization of resources in the whole life cycle of product design, manufacturing, packaging, transportation and recycling.

Its features are as follows:

- Resource utilization – Max

- Waste resources- Min

- Environmental pollution – Min

Green manufacturing is the intersection of three areas:

- Manufacturing

- Environment

- Resources

At present, there is no recognized authoritative definition of green products, but green products should meet the following aspects:

- In its life cycle, it meets specific environmental protection requirements and has no or minimal impact on human body and environment.

- The product structure shall be as simple as possible without reducing functions, so as to save materials and energy.

- At the end of its service life, its parts can be refurbished, recycled, reused or safely disposed of.

A typical example of responding to the concept of green manufacturing is the increasingly popular new energy vehicles. In the sheet metal bending industry, there are oil electric hybrid press brakes, which have the characteristics of high efficiency and energy saving, low noise and environmental protection.

Green and intelligence have always been the two major trends in today’s manufacturing industry. In the future, the manufacturing industry will continue to develop towards more intelligent, energy-saving and environmental protection. Let’s continue to pay attention to intelligent manufacturing and green manufacturing!