In the mechanical industry, hydraulic pressing machines have various structural forms. The structural forms of hydraulic presses for different purposes are also different.

What is a hydraulic press? A hydraulic press is a kind of machine that uses hydraulic oil as the power source. Through the force of the hydraulic pump, the one-way valve makes the hydraulic oil circulate in the oil tank so as to make the cylinder/piston can do work in a cycle to complete a certain mechanical action as a productivity.

From the direction of the force: vertical and horizontal. Most hydraulic presses are vertical. The hydraulic press for extrusion is mostly horizontal.

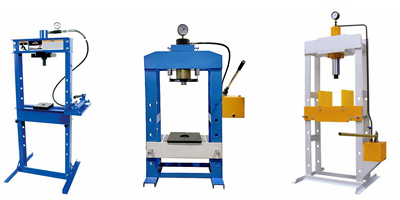

From the frame: column type, single arm type and frame type. The column type is divided into four columns, double columns, three columns and multi-columns.

From the number of working cylinders: single cylinder, triple cylinder and multi cylinder.

Hydraulic presses of different structures and tonnage are selected for different products. The same hydraulic press can also change the mold to complete the processing of different styles of products.

This is a multi-function forging machine tool. It is widely used in aerospace, nuclear power, petrochemical, auto parts, bicycle parts, hardware products, instruments, medical equipment, household appliances, household utensils, sanitary kitchenware and other manufacturing industries.

- Manual hydraulic press

This hydraulic press is used for simple, low-stress jobs that can be performed by hand.

- Hydraulic forging press

Large forging hydraulic press machinery is a forging equipment that can complete various free forging processes. It is one of the most widely used equipment in the forging industry.

At present, there are 800T, 1600T, 2000T, 2500T, 3150T, 4000T, 5000T series of forging hydraulic presses.

- Stamping hydraulic press

Used for stamping and stretching of various thin and thick plates. Among them are single-action, double-action and rubber die stamping.

- General-purpose hydraulic press

include all kinds of universal general-purpose hydraulic presses.

- Calibration and press-fitting hydraulic presses

Used for parts calibration and assembly.

- Laminating hydraulic presses

For the pressing of plywood, particleboard, fibreboard and insulation boards.

- Extrusion hydraulic presses

Used to extrude wires, pipes, rods, profiles and workpieces of various non-ferrous and ferrous metals, such as deep drawing and perforation.

- Compression hydraulic pressing machine

It is used for the compression forming of various powder products. Such as powder metallurgy, artificial diamond, refractory brick, carbon pole, pressing of plastic and rubber products, etc.

- Baling and briquetting hydraulic presses

Used for briquetting and baling metal chips and scraps, as well as baling non-metallic scraps.

If you need to know other hydraulic equipment, you can click here:

- Hydraulic CNC shearing machine

- Hydraulic CNC plate rolling machine

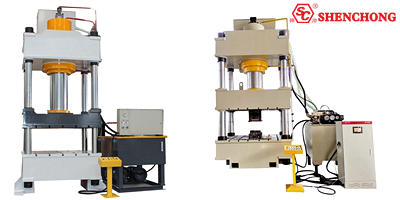

Four column hydraulic press is used for precision tool application. Four column presses provide equal pressure distribution.

The advantage of four column hydraulic press lies in its flexibility and versatility. Smooth transition. Easy to operate. Fast installation and maintenance. Low cost.

Introduction:

The main component of the four-column hydraulic machine comprises two parts host control means. Host part of the fuselage, the master cylinder, the top of the cylinder and liquid-filled devices. Power by the fuel tank, high-pressure pump, low-voltage control systems, motors and a variety of pressure valves and directional valves and other common components. The power mechanism of the four-post hydraulic machine is controlled by the electric device. It uses the pump and the cylinder and different hydraulic valves to carry out the energy conversion, adjustment and transmission, and complete the cycle of various technological actions.

Four-column hydraulic machine features:

- Activity crossbeam travel speed of the pump for liquid decision, nothing to do with the process of forging deformation resistance. If the pump supply is constant, the working speed of the four-post hydraulic press is constant.

- Hydraulic pressure and consumed power with the workpiece deformation resistance related work deformation resistance, liquid supply pressure of the pump and the power consumed is also large, the opposite is small.

- Take advantage of the moving beam travel speed and constant bending hydraulic machine hydraulic pressure changes in the characteristics as a manipulation signal distributor, to achieve automatic control column hydraulic machine.

- Four-post hydraulic machine small investment, small footprint, daily care and maintenance is simple. The hydraulic pump in the direct drive system is selected according to the maximum working speed and working pressure of the hydraulic press, and the hydraulic pump is not fully utilized when the hydraulic filling stroke, return stroke, auxiliary working procedure and required working pressure are small, Especially the large tonnage of the four-column hydraulic press, the utilization factor is very low. Therefore, the four-column hydraulic machine tends to work speed and working pressure for grading drive.

Single column hydraulic press is also called C-frame hydraulic press. Because the main body of the press is a C-type single arm structure.

The advantages of single column hydraulic press are excellent rigidity, guiding performance, speed and high precision. The automotive, electronics, home and medical industries use C-frame hydraulic presses for sheet metal forming, plastic forming, bending, deep drawing and other applications. C-frame press is convenient because of its small size. As small and medium-sized equipment, it does not occupy much space.

Introduction:

The main part of the arm hydraulic machine consists of two parts the host control means. Host part of the fuselage, the master cylinder, the top of the cylinder and liquid-filled devices. Power by the fuel tank, high-pressure pump, low-voltage control systems, motors and a variety of pressure valves and directional valves and other common components. Power mechanism arm hydraulic machine under the control of electrical devices, the use of pumps and hydraulic cylinders and valves of different energy conversion, regulation and delivery, to complete the cycle of operation of various processes.

Single-column machine features:

- Activity crossbeam travel speed of the pump for liquid decision, nothing to do with the process of forging deformation resistance. If the supply amount of the pump is constant, then the operating speed of the hydraulic arm machine is constant.

- The liquid pressure arm hydraulic machine with the power consumed with the workpiece deformation resistance related to the work of deformation resistance, liquid supply pressure of the pump and the power consumed is also large, the opposite is small.

- Take advantage of the moving beam travel speed and constant bending hydraulic machine hydraulic pressure changes in the characteristics as a manipulation signal distributor, to achieve automatic control of hydraulic machine.

- A small investment arm hydraulic machine, small footprint, daily care and maintenance is simple. Pump direct transmission system according to the maximum operating speed of the hydraulic pump and hydraulic machine operating pressure selected, and the arm hydraulic machine in filling stroke, return, auxiliary processes and the required working pressure is small, the hydraulic pumps are not fully utilized , especially large tonnage arm hydraulic machine, its utilization factor is very low. Therefore, single-arm hydraulic machine tends to work speed and working pressure rating drive.

Forging hydraulic machine main components include the host, the control of two parts. Host part of the fuselage, the master cylinder, the top of the cylinder and liquid-filled devices. Power by the fuel tank, high-pressure pump, low-voltage control systems, motors and a variety of pressure valves and directional valves and other common components. Forging hydraulic power mechanism in the control of electrical installations, the use of pumps and cylinders and different hydraulic valve for energy conversion, regulation and transportation, and the completion of a variety of process action cycle.

Forging hydraulic machine features:

- Travel speed of the beam movement of the pump for the fluid, and the process of forging deformation resistance does not matter. If the pump supply is constant, the working speed of the forging press is constant.

- Hydraulic pressure and the power consumption and the deformation resistance of the workpiece, work deformation resistance, the pump for the hydraulic pressure and the power consumption is also large, on the contrary is small.

- Use the activities of beam travel speed constant and bending hydraulic pressure changes, as a signal to manipulate the distributor in order to achieve automatic control of hydraulic press.

- Forging hydraulic press small investment, small footprint, routine maintenance and simple. Pump direct drive system in the hydraulic pump are the maximum working speed and working pressure selected, and forging hydraulic press in the filling stroke, return, auxiliary processes and the required working pressure is small, the hydraulic pump are not fully utilized, Especially for large-tonnage forging hydraulic press, the utilization factor is very low. Therefore, forging hydraulic press tends to work speed and working pressure for grading drive.

Frame pressing machine is also called a single-column hydraulic press and vertical frame hydraulic machine. In fact, oil press machine and hydraulic press is the same concept, but different names it. For example, Taiwanese businessmen call the hydraulic pressing machine "oil pressing machine", and the mainland collectively referred to as "hydraulic press".

There are two types of machine frame: integral type and combined type. It adopts the design of four corner and eight side guide rail, which has the advantages of high precision, strong anti eccentric load capacity, etc.

Vertical frame hydraulic machine is a special hydraulic oil as the working medium, the hydraulic pump as the power source, the use of pump force to hydraulic oil from the hydraulic pipe into the cylinder/piston, and then cylinder/piston in several groups with each other Seals, seals in different locations are not the same, but have played the role of sealing, so that hydraulic oil will not leak. Finally, the use of one-way valve to the hydraulic oil in the tank cycle, the cylinder/piston cycle work, thus completing a certain mechanical action as a mechanical productivity.

Vertical frame hydraulic machine advantages:

Vertical selection overall framework hydraulic machine steel welded frame chassis, the overall rigidity, high compressive strength; pressure, stroke, pressure, etc. can be adjusted according to the requirements of the pressing process; having the ejector, on the entry materials, under complex roof Material or shallow drawing, and other different derived models,

Suitable for a variety of compression molding process needs; clamping pressure from the fast, to the rated pressure only a few seconds; use the lower set-type fuel tank, the replacement and cleaning the fuel tank is very convenient.

When selecting hydraulic pressing machines, the most important and critical thing is to select reliable hydraulic pressing machine manufacturers. Because only reliable hydraulic mechanism manufacturers can provide customers with high-quality solutions and accurately analyze customers' needs. Reliable manufacturers can analyze the products molded by customers, tell users what kind of hydraulic press to use, and give customers the best solution. Of course, the after-sales service is also very guaranteed.