The hydraulic plate rolling machine is a kind of equipment that uses working rollers to bend the sheet metal. It can form parts of different shapes such as cylindrical parts and cones. It is a very important processing equipment for metal processing industries.

The working principle of the hydraulic plate roll bending machine is to move the work roll through the external force of hydraulic pressure, so that the plate is bent or rolled into shape.

According to the rotation movement and position changes of working rollers of different shapes, parts such as oval, arc, and cylindrical parts can be processed.

The upper roller of this machine can be vertically raised and lowered, and the vertical lifting hydraulic transmission is obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod.

The lower roller is driven to rotate, and the output gear meshes through the reducer to provide torque for the rolling plate.

The lower roller has a support roller, and can be adjusted. The upper roller is in the shape of a drum, which improves the straightness of the product and is suitable for various cross-sectional shapes of ultra-long specifications.

The rolling process of the hydraulic plate rolling machine is mainly divided into the following steps:

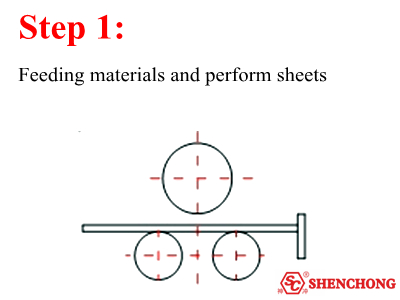

1) Feed the sheet material and perform the material matching

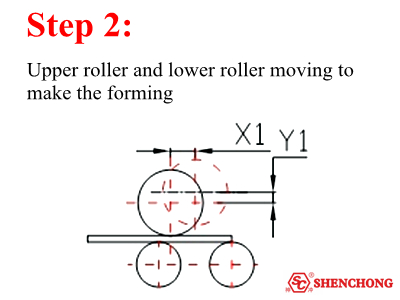

2) The upper roller moves horizontally to the X1 position, then descends to the Y1 position, and the lower roller reverses to make the steel plate to the forming position;

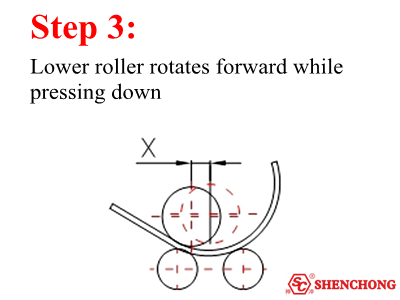

3) The lower roller rotates forward while pressing down;

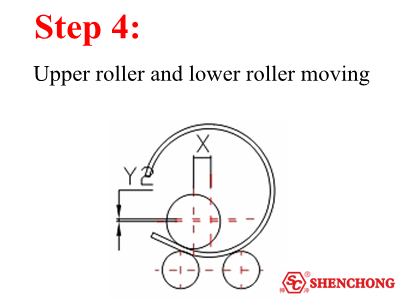

4) The plate bending roll machine upper roller presses down to the Y2 position, and the lower roller continuously rotates forward;

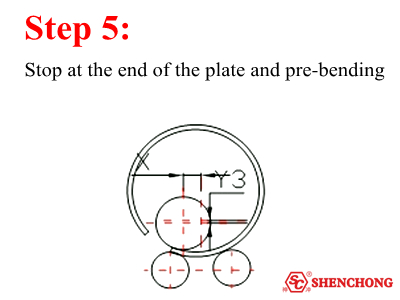

5) Stop at the end of the plate, stop by pressing Y3 on the upper roll, and directly press and pre-bend the end of the plate;

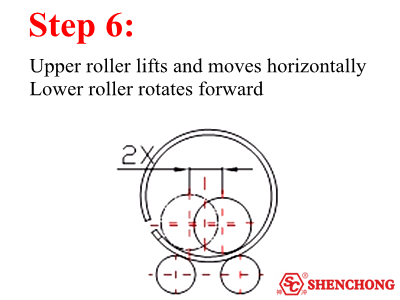

6) The upper roller is lifted to Y2, moved horizontally to the X position, and the same position Y2 is pressed down, and the lower roller rotates forward;

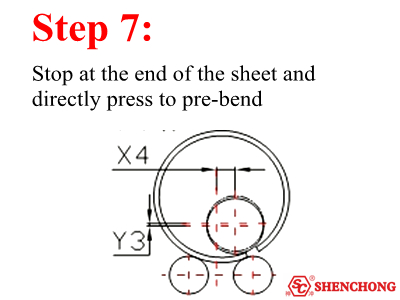

7) Stop at the end of the sheet, stop at Y3 position by pressing with the upper roller, and directly press and pre-bend the end of the sheet;

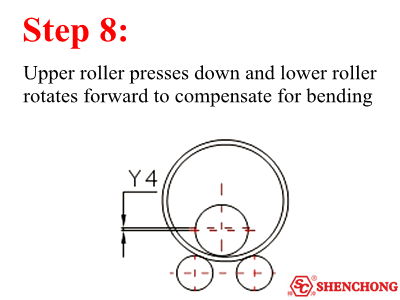

8) Move the upper roller to the X position, press down to the Y4 position, and the lower roller rotates forward and backward to compensate for bending.

In general, the Shenchong hydraulic plate rolling machine adopts the upper roller lifting hydraulic transmission and horizontal movement, driven by the lower roller, and the electric centralized control operating system, which can complete the pre-bending of the two ends of the plate and roll the cylindrical and arc-shaped workpieces at one time. It can also perform certain shaping and leveling of the metal sheet, which has the effects of direct pre-bending, saving trouble and saving materials, and is equipped with NC system control to improve the degree of automation.