The core component of the pipe laser cutting machine is the laser. The power of the laser determines the range of cutting thickness of the equipment. Usually when purchase pipe laser cutting machines, the corresponding power will be matched according to the material to be processed. Faced with the various specifications of power on the market, how should we choose the appropriate power?

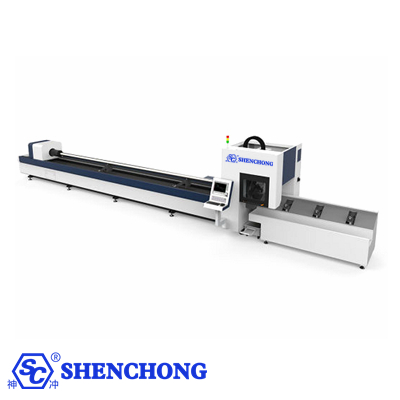

Pipe laser cutting machine is an efficient and precise pipe processing equipment, which widely used in industrial fields. Pipe laser cutting machine adopts laser technology to cut pipes, can achieve high-speed, high-precision cutting effects.

Laser cutting refers to a processing method that uses laser beam to cut objects. Laser beam has the advantage of high energy density and small heat-affected zone. The Pipe laser cutting machine is designed based on the principle of laser cutting.

The pipe laser cutting machine mainly consists of the following components:

- Laser: used to generate high-energy, high-concentration laser beam.

- Optical system: used to focus and guide the laser beam.

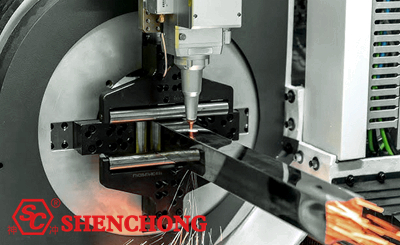

- Cutting head: used to focus and irradiate the laser beam onto the pipe.

- Control system: used to control pipe laser cutting machine movement and cutting parameters.

The pipe laser cutting machine working process can be divided into the following steps:

Set appropriate cutting speed, power and other parameters according to pipe material and cutting requirements.

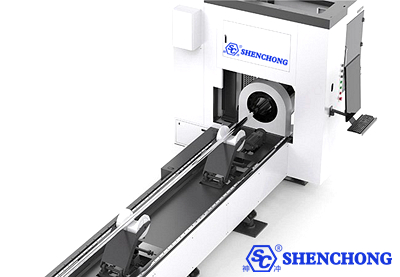

Place the pipe on the workbench of the pipe laser cutting machine, and fix it.

Start the pipe laser cutting machine. The laser produces laser beam, after focusing and guiding by the optical system, the laser beam irradiates onto the cutting head, which is focused into a high-energy laser beam.

The laser beam irradiates the pipe, the surface of the pipe instantly melts and vaporizes due to the high-energy laser beam, forming a molten pool and ejecting gas.

The control system of the pipe laser cutting machine controls the cutting head movement on the pipe, cuts the pipe by the laser beam moving.

After the pipe is completely cut, the pipe laser cutting machine stops and the cutting is completed.

Pipe laser cutting machines have the following advantages over traditional cutting equipment:

- High precision: The diameter of the laser beam is small, enabling high-precision cutting

- High efficiency: Laser cutting speed is fast, which can greatly improve work efficiency.

- Flexibility: The pipe laser cutting machine can be adjusted according to different cutting requirements to adapt to different processing needs.

- Good cutting quality: The laser cutting surface is smooth, the heat affected zone is small, and the cutting quality is good.

- High automation: The pipe laser cutting machine is equipped with a control system, which can realize automatic operation and reduce manual intervention.

Pipe laser cutting machines are widely used in the following fields:

- Metal processing: Pipe laser cutting machine can be used for cutting, perforating and other processing of metal pipes.

- Electronic device manufacturing: Pipe laser cutting machine can be used for processing electronic devices, such as cutting circuit boards, electronic components, etc.

- Automobile manufacturing: Pipe laser cutting machines can be used for cutting pipes, exhaust pipes, etc. in automobile manufacturing.

- Architectural decoration: Pipe laser cutting machine can be used for cutting, engraving and other metal pipe processing in buildings.

The materials cut by pipe laser cutting machines are metals, mainly stainless steel, carbon steel, aluminum plates, brass, etc. The higher the power of the equipment, the thicker the cutting thickness. The power mainly depends on the laser. In the market, 6000W and above are generally called high power, the power between 3000W and 6000W is medium power, and the power below 3000W is called low power.

Judging from the current market demand, laser cutting machines with a power of 6000W and below can meet the cutting needs of most customers. These equipments are also used more. The higher the power of the equipment, the faster the cutting speed of the same material. The faster, but an important factor in measuring the price of a laser cutting machine is the power of the laser.

The core component of the pipe laser cutting machine is the laser. The power of the laser determines the range of cutting thickness of the equipment. Usually when purchasing pipe laser cutting machines, the corresponding power will be matched according to the material to be processed. Faced with the various specifications of power on the market, how should we choose the appropriate power?

There are two factors to consider when purchase pipe laser cutting machines. First, the laser cutting machine power can meet your cutting requirements. Second, whether the machine price meet our budget. The power of the laser cutting machine is one of the core parameters of the equipment.

The pipe laser cutting machine can do complex multi-step processing. Sawing, drilling, grooving, and grinding can be completed with just one machine, while eliminating intermediate logistics links and warehousing costs. Comparing with traditional cutting processing, the processing cost of pipe laser cutting machine is much lower.

The pipe laser cutting machine can design and instantly cut various complex graphics or text. It can process a variety of shapes on the surface of the pipe, triggering more new pipe design inspiration, helping us quickly complete the development of new products and reducing costs.

The pipe cutting machine has a user-friendly structural design, and the machine tool can receive signals, making loading materials easy and greatly improving production efficiency.

All kinds of pipes regardless of diameter can be switched freely without changing the clamps.

Save labor and improve efficiency.

Automatically collects long workpieces, protects the appearance of the workpieces, saves labor, and improves efficiency.

human-machine interface combined with remote control operation is simple and convenient.

When the pipe laser cutting machine cuts thin sheet metal, low-power equipment is completely sufficient. For example: stainless steel plate thickness 3mm, we can choose model 3000W and air cutting, which not only cuts quickly, the cutting quality is also very fine, can save costs.

Therefore, when we buy pipe laser cutting machines, we should make a reasonable choice based on our material, material thickness, etc., and not pursue a high power. Of course, if you process both thick and thin plates and have large production capacity requirements, a high-power laser cutting machine within the price range will be a better choice. By appropriately adjusting the cutting speed and replacing the auxiliary gas, high-power laser cutting machines can also control the cutting quality very well when cutting thinner plates.