Nowadays, the manufacturing factory has started to upgrade the intelligent workshop to improve productivity and safety. So how should the factory automate sheet metal production?

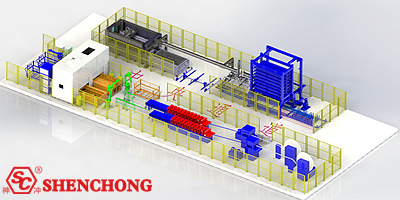

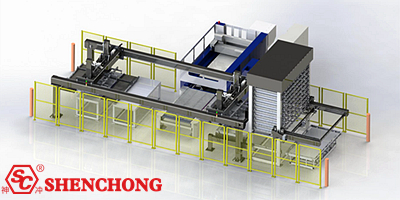

The realization of flexible production line mainly starts from two key points: the new automation system and the CNC machine tools that have been put into use. The factory should be reformed and upgraded from these two aspects.

With the popularization of robots and automation technology in sheet metal manufacturing, we should be prepared for the influx of these new technologies. Before realizing the automation upgrade, the factory must take the following three key points.

Realizing the automation of sheet metal production does not necessarily mean completely abandoning the original equipment and production line. It is unrealistic to completely replace the entire production line with new machines.

This is not only an extremely expensive project, but also the procurement and transportation of new equipment will cause certain downtime. This will cause certain economic losses and adverse effects to the factory.

Therefore, we suggest you’d better to start the automatic transformation slowly. Step by step, benefit from it and repeat. And, you should invest at a specific pain point and leverage the benefits of these investments for further automated development.

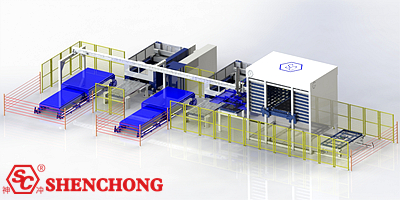

- The correct layout of new equipment is crucial for safety, ergonomics and efficient production.

If the floor plan of the whole workshop is not considered before installing the new machine, it is likely to cause large losses, delayed production and wrong shutdown.

Whether adding new assembly lines or single equipment, it is easy for users to ignore the impact of the new sheet metal automation machine on the original production.

- Handling and transportation of raw materials should be given due attention.

- In addition, when adding a new CNC machine tool or robot, it is also very important to determine their position or order on the production line.

Reasonable arrangement and layout can reduce the total production time and reduce the risk of material transportation in the workshop.

Although it is not easy to draw the factory layout, there are a large number of simulation software packages available for layout planning before purchase and installation. This digital spatial simulation enables users to see the impact of the new machine on the entire workshop.

Automating sheet metal production does not mean completely replacing labor. Although automation can eliminate some manual procedures, the focus and advantage of automation is actually to improve productivity, consistency and efficiency.

This is the paradox of automation. Because when you use sheet metal automation efficiently, the importance of human intervention will increase, but the frequency will decrease.

In fact, automatic production is not the magic weapon to reduce workload. It is aimed at enabling more experienced employees to focus on more important problems and solutions, rather than being trapped in trivial daily tasks that are repeated.

- Balance labor force

We can find that employees in the workshop are composed of groups with different ages, different skills and different ideas. The diversity of employees leads to their inability to adapt to automation.

When automate sheet metal production, we cannot ignore the cooperation of human.

Young employees may have used similar robotic sheet metal processing equipment. But older employees who are accustomed to traditional equipment may feel left behind.

Therefore, it is very important to carry out differentiated training for different employees without reserving knowledge in advance. In an organically developed factory, a good way to improve everyone's skills is to cultivate a spirit of knowledge sharing and material rewards.

Remember that manpower is always critical in the automation process of maintenance, implementation and monitoring. Business owners should remain sober when introducing new things!

In some industries, manual processing will always occupy a place. However, CNC machine tools and automatic sheet metal production lines are expanding the labor force to a new level of knowledge and paving the way for the new development of the factory.

Learning to set up or program automatic machines can free employees from daily trivial work, so as to focus on more professional and higher-level problems rather than low-level manual labor. Flexible automation will not make employees redundant, and employees can also benefit from it. The ideal state is that manual and automatic equipment work together, which can improve efficiency and profit to a new level!

Artificial intelligence has quietly entered our lives and is changing the world in a profound and exciting way. With the prevalence of knowledge sharing, AI has developed rapidly in recent years. The factories should start to automate sheet metal production as soon as possible and continue to advance in an orderly manner.

Wuxi Shenchong Forging Machine Co., Ltd. is an enterprise specializing in production of press brakes, shearing machines, rolling machines and sheet metal automation. We have built a sustainable production advantage in the field of sheet metal automation. With further development and research of automation technology, it will be more efficient, accurate and future-proof. Belive that “Intelligent Manufacturing Redefines Your Future”!