Guillotine Shear Controller ELGO P40 is 1 or 2 axes position controller control system for sheet metal machines. It has one or two axis version by LCD display. It has the advantages of easy handling, multi-lingual menu navigation, option PID analog output available, reference run, and manual, single program mode.

Guillotine Shear Controller ELGO P40 position controller for 1 or 2 axes for metal machines:

- One or two axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual, single and program mode

- Positioning of back gauge, gap and angle.

- Manual inching, single or program operation

- 16 freely configurable inputs and outputs

- Programme memory with 500 blocks

- LCD display with four menu languages

- Optionally with 12 bit analog output(selectively PID or unregulated)

- Material depending voltage output

- Simple and intuitive handling

- Integrated diagnosis mode

- Easy panel installation

The guillotine shear controller P40 was designed for simple positioning applications on cnc hydraulic guillotine shears. The focus is on the easy, convenient and fast input of a target value, optionally a number of pieces as well as a cutting angle (auxiliary axis) or a cutting gap (auxiliary axis). The actual value, target value and quantity are displayed on the control panel via an easy-to-read LCD display. The target value as well as the desired quantity can be entered via the keypad and positioning can be started and stopped via front start button.

The guillotine shear cutting angle or cutting gap can be displayed and positioned via the second encoder input. This encoder input can optionally be designed for analog measuring systems (see "Drive signals for positioning" below).

In addition to manual inching and single operation, the guillotine shear ELGO P40 controller has a program mode that can be activated directly by the program key on the front panel. The program memory is designed for a maximum of 500 blocks.

- Adjustable positioning output signals (3 different speeds)

- Visualization of the actual and the programmed position

- Absolute or incremental measurement positioning

- Reference value and gauging

- mm/inch - switchover

- Impulse factor and multi edge counter

- Tolerance window

- Software end limit monitoring

- Loop operation

- Program memory with up to 500 blocks

- Tool compensation

- Encoder monitoring

- Batch counter

- Manual inching mode

- Stroke control

- 20 offsets

- Retract function

- Actual position memory

- Positioning oft the backgauge axis

- Cutting gap / cutting angle control

- Material table for the auxiliary axes cutting angle and cutting gap

- Metal shear specific parameters e.g. knife length, cutting time, knife lowering time

Depending on the encoder or measuring system used, the inputs for 1 or 2 axes can be configured individually. Conventional square wave inputs with HTL or differential TTL characteristics are available. When using analog measuring systems for the auxiliary axes cutting angle and cutting gap, the controller can also be equipped with 1 or 2 analog inputs. Combinations of digital and analog inputs are also possible. However, the restrictions listed in the type code should be taken into account.

Three different versions of output signals are available for positioning:

1) Switch-off positioning with up to 3 speeds via digital outputs.

The assignment and logic (active HIGH/LOW) can be parametrized.

2) Optionally via unregulated 12 bit analog output (±10 V)

3) Optionally via regulated 12 bit PID analog output (±10 V)

(order codes see type designation)

For diverse control commands, the P40-002 controller is equipped with 16 digital PNP inputs and outputs whose pin assignment and switching logic are freely configurable via parameters.

Click here to know other shearing machine controller:

DELEM DAC 360 CNC shearing machine guide

Housing | panel housing |

Housing material | front plate: aluminium Housing: galvanized steel sheet |

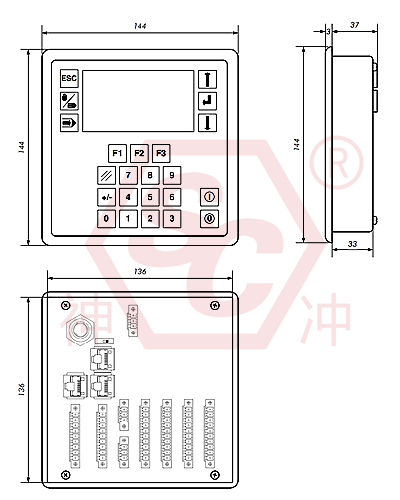

Front plate dimensions | WxH=144x144 mm |

Panel cut out | WxH =138x138 mm |

Keyboard | foil, short stroke keys |

Installation depth | 37 mm (without connectors) 75 mm (with connectors) |

Display | LCD dot matrix120x 80 pixels with white background lighting |

Hardware | 32 bit microcontroller with 1 MByte Flash and 56 KByte RAM |

Program memory | up to 500 blocks (more on request) |

System accuracy | ±1 increment |

Power supply voltage | 24 VDC +10/-20% |

Current consumption | max.150 mA (unloaded); permitted tot. current incl. self-consumption:1A |

Encoder supply voltage | 24 VDC or 5 VDC |

Load by measuring system | max.130 mA |

Input signals (encoder) | HTL,TTL,analog (order dependent) |

Signal channels | A,B,Z resp.A,A',B,B',Z,Z'or analog 0 ... 3.3 V (order designation) |

External inputs | 16 x digital PNP inputs with freely programmable assignment and logic |

Input current / pin | max.10 mA |

Pulse time for inputs | min.300 ms |

Max.input frequency | 100kHz (higher on request) |

Analog inputs | optional 1 or 2 analog inputs (12 bit) at 3.3 VDC sensor supply |

Output signals | 16 digital PNP outputs with freely programmable assignment and logic(active high/low) |

Output current | max.150 mA per output/500 mA total current across all outputs; the outputs are durable short circuit proof(no multiple short circuits) |

Freewheel clutch / outputs | for inductive loads integrated (clamping voltage at the output max.-45V) |

Analog outputs | optional:± 10 V PID or ±10V unregulated (each 12 bit) |

Connections | industry standard connectors (3.81mm grid, lockable) and additional RJ45 sockets (depending on version) |

Power down memory | E2Prom (service life:1.000.000 switching on/off cydes or 40 years) |

Further options | 8 = only 8 instead of 16 1/Os |

Operating temperature | 0.. +45℃ |

Storage temperature | -20... +50℃ |

Humidity | max. 80 %, non-condensing |

Protection class (front) | IP43 (installed state) |

Protection class (rear) | IPO0 |

P40 - _ _ _ - _ _ _ - _ _ - _ _ - _ _ _ _

AAA - BBB - CC - DD - EEEE

- A: Version

002= special version for cnc hydraulic guillotine shears

- B: Power Supply

024= 24VDC (+10/-20%)

- C: Encoder Inputs

X = input is not available

1 = A,B, Z (PNP) 24 V supply / HTL, 100 kHz

2 = A,A‘, B, B',Z,Z' 24V supply /TTL 100 kHz

3 = A,A', B, B‘,Z, Z' 5 V supply / TTL 100 kHz

4= 1 analog input 3.3 V supply / 0 ... 3.3 V (12 Bit)'

5= 2 analog inputs 3.3 V supply / 0 ... 3.3 V (12 Bit)'

- D: Outputs (drive signal per axis)

X = no output available

0 = digital transistor outputs, PNP

1 = 12 bit analog output ±10V (PID regulated)2

2 = 12 bit analog output ±10V (unregulated)

- E: Options (multiple indications possible)

X = no further options C=screw terminals

8 = 8 digital inputs / 8 digital outputs3

Restrictions:

1) not for axis 1 (only for auxiliary axes)

2) not available, when analog measuring systems are used (D = 4 or 5)

3) 3 not available in combination with an analog output

P40 - 002 - 024 - 15 - 10 - CXXX

AAA - BBB - CC - DD - EEEE

P40 special version for CNC guillotine shears with 24 VDC power supply, 1 HTL input for encoder channels (A, B, Z,) 2 analog inputs for auxiliary axes (angle and gap), 1 regulated PID output for positioning the first axis, digital PNP transistor outputs for positioning the second axis and connections by optional screw terminals.

Order Designation | Description |

NG13 | Power pack for AC-supply (primary: 115/230 VAC,secondary:24 VDC/600 mA) |

RP8 | Relay card with 8 changeover relays (28 VDC/250 VAC/12 A) |

P40 Interface Cable | Interface cable for PC connection (withRJ45plug and female 9-pin SUB-D) |