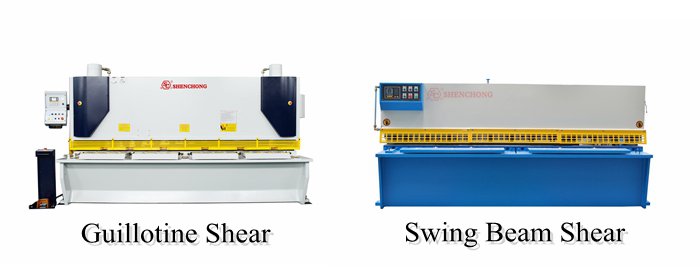

Hydraulic guillotine shears have higher accuracy than hydraulic swing beam shears

(1) Taking 16*3200 hydraulic swing beam shears and hydraulic guillotine shears as examples, the swing beam and guillotine edge.

The calculated clearance values are all less than 6 mm, but the clearance of the bearing connection between the swing arm and the swing frame body of the swing beam machine cannot be eliminated.

In addition, the accumulated shearing accuracy error of clearance and edge clearance is generally more than 10 mm, while the rear guide rail of the guillotine shear body is supported by 4 large bearings, and the front guide rail is pressed by 2 bearings with compression springs behind them. Tight, so that there is no clearance between the front and rear guide rails, and the added accuracy error of the clearance and the edge clearance is kept below 4 mm, so the sheared material is smoother and free of burrs.

(2) The tool holder of the swing beam shearing machine itself is arc-shaped, which ensures the straightness of the sheared material by the point contact of the arc, while the tool holder of the guillotine shearing machine operates relative to the lower blade. Vertical linear movement to ensure less distortion and straightness of the sheared sheet.

(3) Because the force point of the tool holder and the blade edge are not on the same line and the distance is far away, the tool holder is prone to fatigue and deformation after long-term work, which makes the knife phenomenon more serious, resulting in burrs in some cuts of the sheared material, while the guillotine shearing machine is prone to fatigue and deformation after long-term work. The shearing machine is not easy to deform because the oil cylinder, the tool holder and the blade are in the same line and move perpendicular to the lower blade.

(1) The shearing angle of the swing beam shearing machine is a fixed angle, and the shearing speed cannot be adjusted.

(2) The guillotine shearing machine realizes the angle adjustment by adjusting the oil volume of the closed cavity connected in series between the two engineering oil cylinders. Working time, the bending of the sheet is effectively reduced.

(1) Because the blade point of the swing beam shearing machine tool holder moves in an arc when working, only the diamond-shaped blade with two edges can be used; while the guillotine shearing machine tool holder moves in a straight line perpendicular to the lower edge, directly The use of rectangular inserts with four-sided cutting edges doubles the life of the cutting edge.

(2) The diamond-shaped blade shears the sheet, which is easy to cause twist-like distortion of the sheet. The narrower the cut material, the more serious it is, while the rectangular blade can avoid this defect.

Know More About CNC Hydraulic Shearing Machine

The semi-circular block of the built-in oil cylinder used in the swing beam shearing machine is difficult to lubricate and repair, while the upper and lower chambers of the oil cylinder of the guillotine shearing machine project do not need additional lubrication, thus greatly improving the service life.

1) The second generation CNC hydraulic guillotine shearing machine is an ideal replacement product of hydraulic swing beam shearing machine.

2) The frame adopts a closed integral steel plate welded structure, and the stress is eliminated by vibration (good precision retention).

3) Adopt advanced integrated hydraulic system (less faults, easy maintenance), high pressure oil pipe (easy maintenance, easy replacement), simple layout, good reliability and beautiful appearance.

4) Three-point support rolling guide is adopted to eliminate the support gap and improve the shearing accuracy.

5) The cutting edge gap is electrically adjusted quickly, and the liquid crystal display is accurate and convenient.

6) Shearing angle hydraulic and electric control stepless adjustment: increase the shearing angle to increase the shearing capacity (suitable for overload shearing), decrease the shearing angle to increase the shearing speed (up to 8~20 strokes per minute when shearing thin plates).

7) Electric back gauge, LCD digital display, single micro-tuning.

(1) The shear angle of the hydraulic swing beam shearing machine is fixed and cannot be adjusted, and the efficiency of shearing thin plates and thick plates is the same, which means that a lot of power resources and operating hours. For example: the motor power of a QC12Y-10X2500 hydraulic shearing machine is 55KW, and the 10mm thick sheet is cut 8 times/min. Because the shearing angle cannot be adjusted, the same 5mm thick sheet is cut 8 times/min.

(2) In order to reduce the deformation of the frame and reduce the power of the machine, the shearing angle of the swing beam shearing machine usually takes the maximum value, but the larger shearing angle when shearing thin plates will make the shearing The workpiece has a large bending deformation.