Springback is always a difficult problem when bending sheet metal parts. What is it? Why does spring back occur in bending operation? How to reduce? The following is a detailed explanation.

We all know that springback occurs during sheet metal forming. So, do you know how the springback of bending is formed? Next, we will give you a detailed answer.

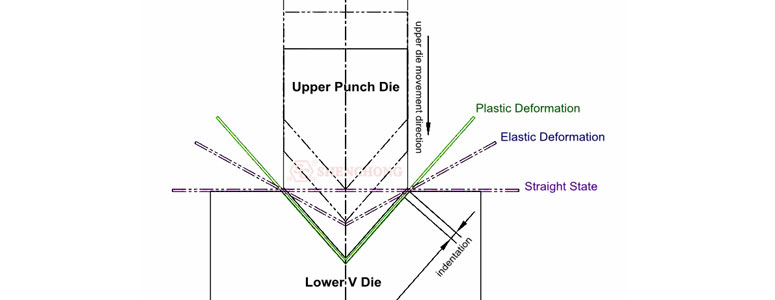

In the process of bending forming, the blank will produce plastic and elastic deformation under the action of external load.

Once the external load removed, the elastic deformation will disappear immediately, while the plastic deformation can continue.

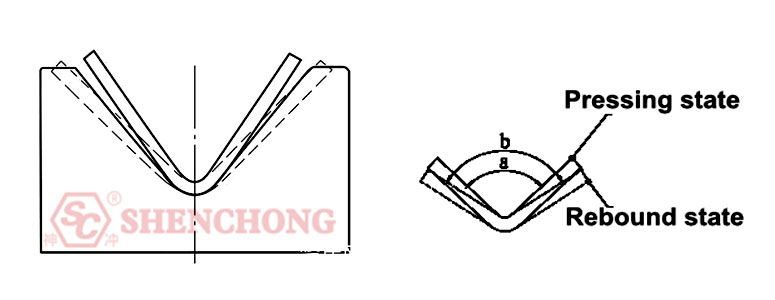

Due to the existence of elastic deformation, the shape, position and size of parts will produce deformation opposite to the loading direction, which is rebound.

Especially in recent years, the requirements for product precision have become higher and higher, and the prediction and control of springback have become more important and difficult.

The influence factors of springback are complex. To ensure the quality control in the springback process, it is necessary to analyze its influencing factors.

Spring back is the most difficult to control in bending process. When the sheet metal unloaded, it will produce elastic deformation and affect the shape accuracy of sheet metal parts.

When springback occurs, we need to constantly test and repair the mold, resulting in an increase in the cost of production. This is our urgent need to take effective measures to overcome or improve.

Cause analysis and corresponding measures are as follows:

Material selection depends on the mechanical properties of the material.

That is, the higher the yield limit of the material and the smaller the elastic modulus, the greater the rebound after bending. The more serious the work hardening phenomenon, the greater the spring back.

Therefore, in order to prevent the influence of the material on the springback, the process designer should try to choose a material with a small yield point, a large elastic modulus and a small hardening index.

Servo Hybrid Press Brake For Sale

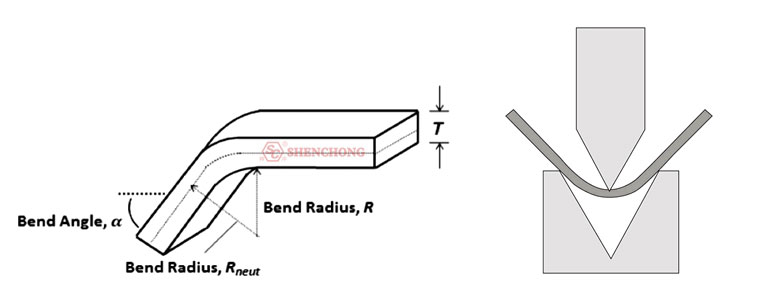

When the sheet metal bent, the relative bending radius R/T:

When this value is small, the total strain of the tangential deformation of the inner and outer surfaces of the part is large, and the resulting elastic strain decreases accordingly. In this case, the rebound amount is small, otherwise it is large.

Therefore, when bending sheet metal parts, the relative radius must exceed the scale factor, but the smaller coefficient value should be selected as far as possible.

In addition, on the premise of ensuring the use of sheet metal parts, we can press stiffeners in the bending area. This can increase the inertia moment of the part interface to restrain the springback.

When bending, the greater the bending angle, the greater the length of the deformation zone and the greater the springback angle.

In actual production, the greater the applied bending force, the greater the deformation, and the smaller the springback.

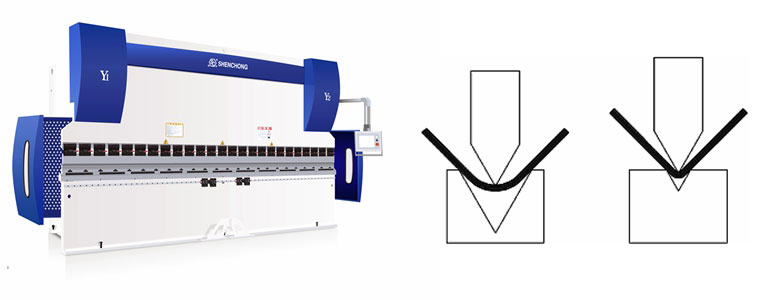

Finally, when the bottomless die is used for free bending, the amount of springback is large.

Conversely, when correcting the bending, the mold is corrected with a V-shaped piece, and the springback is small.

In view of the above factors, the process can use the law of rebound angle:

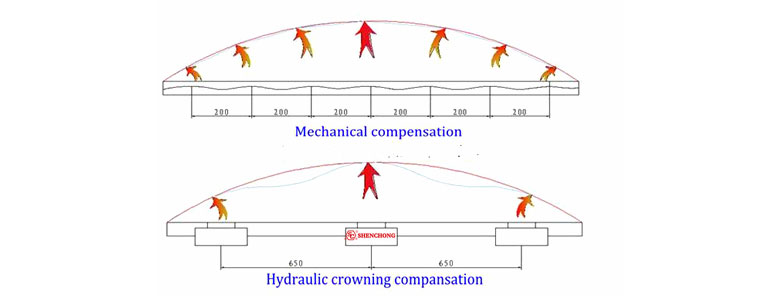

In the mold design, we can calculate the compensation. After debugging the die, the springback of the bending part is compensated. On the CNC press brake, the common compensation methods are hydraulic compensation and mechanical compensation.

In addition, we can adopt the following measures in the structural design of the mold:

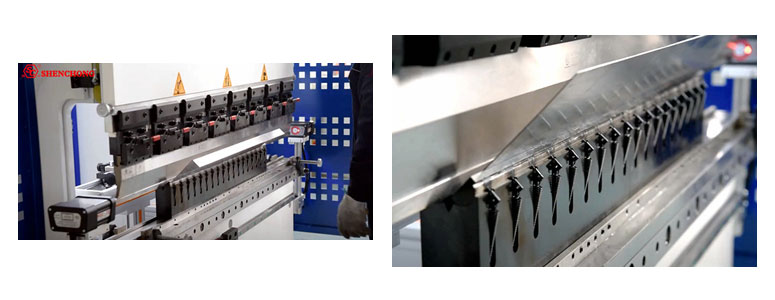

① For the root foot part of the punch of the bending mold, a convex structure can be designed. This part can make the force of the punch better concentrate on the bending part after the bending finished. And tangential deformation will occur inside the extruded part to alleviate the problem of spring back.

② For the concave part of the bending die, a soft rubber material or polyurethane material can be used instead of the original material. Thereby, the pressing depth of the punch is adjusted to ensure spring back. In the press brake tooling, we can customize special molds.

The springback of a bent part is also affected by various factors such as part shape, sheet thickness deviation, sheet performance fluctuations, die gap and die fillet radius.

In actual processing, springback is the most common quality problem of sheet-metal bending. The above is factors analysis and control methods of reducing spring back during sheet metal bending. Controlling this problem is helpful to improve the quality of bending work piece. We should pay more attention to it in production!