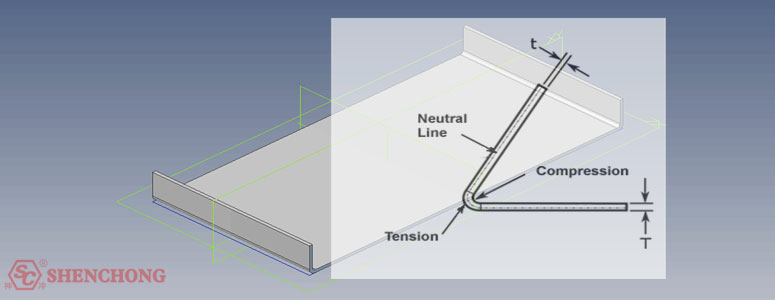

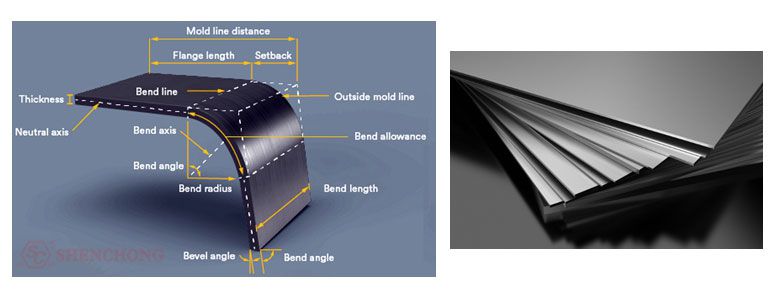

Bending refers to the forming method of processing plate, bar, tube, pipe or profile into parts with a certain angle and shape. This is a common process in sheet metal stamping.

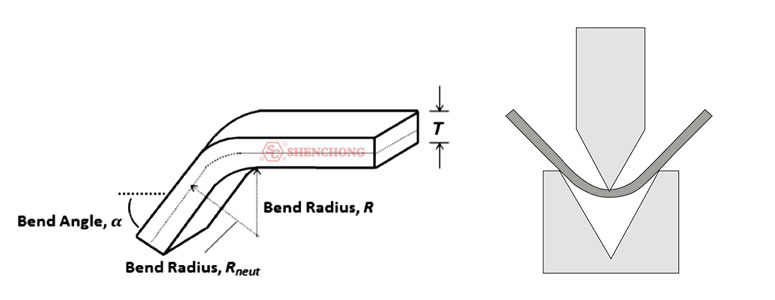

Generally speaking, the bending process needs to ensure the fillet radius of the bending part, the structure, shape and size of the part.

In practice, the most common quality problem of sheet metal bending is spring back, then is crack, and others include warping, twisting, dimensional offset, hole offset and other problems.

Taking the two most common materials of stainless steel and aluminum as examples, this paper mainly analyzes the problems of spring back and cracks produced by processing, and gives quality control measures.

Stainless steel is a kind of material with high yield point and hardness. This material is easy to produce cold work hardening effect.

Therefore, when bending it, the problem of controlling the quality of the work piece is also very troublesome!

When bending, stainless steel has the following characteristics:

- Because stainless steel belongs to high carbon steel, its thermal conductivity and ductility are relatively low. So the bending deformation process requires greater external force and greater rebound.

- The lower ductility makes the bending radius R of stainless steel parts must be greater than that of ordinary carbon steel materials. Otherwise, cracks are easy to occur at the bend.

- As the stainless steel material itself is easy to produce cold work hardening, the tool with high hardnessshould be used during bending. Tool steel is generally selected as tool material. Carry out quenching heat treatment before use to ensure that the hardness of the tool is above 60HRC. And the surface roughness should be guaranteed within 2μm.

The key points of quality control of stainless steel plate bending are as follows:

1) Crack

Under the unit size of the crack , the larger the thickness of the stainless steel plate, the bending angle should be increased as much as possible.

The required bending force is also greater. The bending allowance on one side is also increased. In this way, quality problems such as cracks can be prevented during bending.

2) Accuracy

According to the material thickness, bending radius and bending angle given in the drawing, we can calculate the unfolded size of the stainless steel plate accurately.

Pay more attention to the thickness tolerance range of the material to ensure that the bent product can meet the final bending accuracy requirements, thereby improving the one-time forming rate of bending.

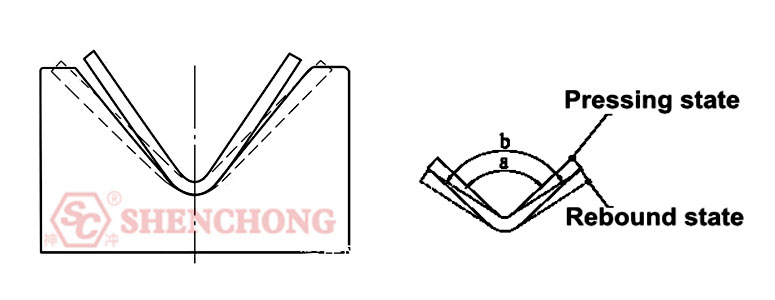

3) Spring back

Due to the high yield strength of stainless steel, the rebound is also large. The spring back of stainless steel is indeed a difficult problem in production.

In view of this phenomenon, if the angle is in place in the bending process, the tool angle used in bending should be less than the actual bending angle.

The second is the hardness of the material. The greater the hardness, the greater the rebound.

In addition, it is also related to the ratio of bending radius to material thickness. The greater the ratio, the greater the rebound.

The springback of different grades of stainless steel is also different, among which 301 has greater springback than 304. Under the same premise, the rebound of 304 is 2 degrees smaller than that of 301.

Finally, the difference of forming methods will also lead to the difference of springback. The springback of one-step forming is larger than that of multiple forming

The rebound value can be corrected after mold test. Note that each springback has angle springback and radius springback.

In actual production, we should analyze the specific situation to ensure the bending quality.

Other stainless steel information:

Stainless Steel Surface Treatment And Processing Technology

The springback of aluminum plate after bending will not be repeated. However, if the cracking problem is obvious during the bending process, or it bursts after the anodized surface treatment after bending, the cracking problem must be solved.

1) Hardness

This is related to the hardness of the aluminum plate. If the hardness of the aluminum plate is too high, it is easy to crack.

For example, our commonly used T-state aluminum plate:

Then it is necessary to heat treat to O state in advance. The heat treatment methods include annealing and quenching.

The difference between annealing and quenching:

The quenched part needs to be bent within four hours. Otherwise, aging in air will restore the material to a hard state. The annealed material is always in a soft state.

In addition, in terms of processing technology, quenching is more difficult than annealing.

2) Thickness

Next, is the influence of the thickness of the aluminum plate. The thicker the material, the more difficult it is to bend. Should try to use thinner aluminum plate.

3) Bending angle

In addition, the size of bending R is also affected by it. The larger the R angle is, the less difficult it is to process.

Therefore, on the premise of meeting the assembly requirements, we can appropriately increase the R value.

4) Texture direction

Finally, the grain direction of the aluminum plate is what we usually call the fiber direction.

The bending direction should be consistent with the fiber direction, not parallel.

Aluminum parts requiring wire drawing should be bent and then drawn on the premise that the process allows. The probability of cracking will be increased otherwise.

In a word, there are still many places to pay attention to in the quality control of sheet metal press brake bending. In the actual processing, we should make reasonable analysis according to the actual situation and standards, so as to make qualified parts.