Truss robots are mainly used for carrying or loading functions, and are commonly matched with CNC machine tools, CNC machining centers, intelligent warehouses, and so on.

With automation via gantry robots, customers can always ensure that the workpieces to be processed meet increasingly stringent quality requirements. Customers can also complete assembly and more. Customers are able to respond flexibly even as technology evolves rapidly.

By using truss robots to achieve sheet metal automated production, the production capacity of machine tools can be significantly improved. This way, you can shorten the delivery time. You can be profitable and produce even highly complex workpieces.

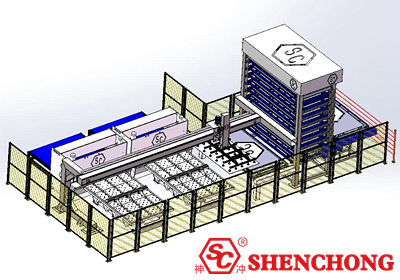

Robots can connect multiple processes. Alternatively, feeding multiple machine tools from one material source or supplying workpieces from different sources to one machine tool.

Truss robots can reduce the simple processing steps of machine tools, thereby improving their productivity. In addition, it can also replace workers in completing processing steps such as brushing or deburring, allowing workers to engage in higher requirements of work.

The truss robot can directly change tools on the machine tool. The number of cutting tools is only limited by the robot's working range. By using linear sliding rails, the working range of the robot can be arbitrarily expanded, allowing one robot to supply multiple machine tools.

The robot provides the workpiece to the machine tool and takes it out again after processing.

Truss robots can load different workpieces into containers. Collaborate with intelligent sheet metal storage systems to sort and stack raw materials or finished products.

A truss robot is a cartesian coordinate type robot that walks on a truss. Truss robots generally have three axes X, Y, and Z, and are equipped with fixtures of different structures to achieve precise machine tool clamping and loading and unloading.

The machining of multi joint truss robots can effectively reduce the transformation of reference planes. This type of processing effectively integrates processes. Not only does it improve the effectiveness of the process, but it can also achieve one-time clamping of the workpiece, making it easier to ensure machining accuracy.

In the current market, multi line truss robot processing equipment is relatively expensive, but it integrates multiple processes, reducing the number of equipment, fixtures, workshop area, and equipment maintenance costs. To some extent, it has compressed costs.

Multi line truss robots can effectively shorten the production process chain and simplify production process management. For complex workpiece processing, the advantages of multi line truss robot equipment are more obvious. The shortening of the production process chain is also beneficial for reducing production operation and management costs.

For enterprises in fields such as aerospace and automotive processing, new product parts will be relatively complex and have high precision requirements. This requires the equipment to have high-precision, high flexibility, and high integration processing capabilities. Multi line truss robots can effectively perform this task and shorten the development cycle.